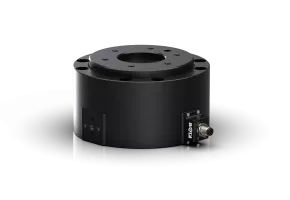

Robotiq Sanding Kit Specifications

Ranked Nr. 131 of 116 End of Arm Tools

- Reduce programming time from hours to minutes

- Automate sanding tasks the easy way

- The only hardware and software sanding solution for Universal Robots

- Increase quality and productivity

- Reduce worker injuries

| Type |

|

| Extra info | Kit includes: 1. Orbital Tool / 2. Bracket / 3. Sanding Media / 4. Finishing Copilot / 5. Quick Start Guide / 6. Air control Accessories |

Sanding Kit Downloads

SANDING KIT product sheet MR2019

You need to

register

to download this file.