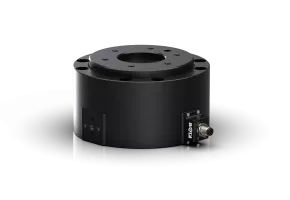

SCHUNK SWS-L Specifications

Ranked Nr. 34 of 116 End of Arm Tools

Pneumatic tool change system with patented locking system for heavy loads

| Type |

|

| Repeatability | mm |

| Product mass | 2.6-19.3 kg |

| Payload | 300-1350 kg |

| Extra info | Patented fail-safe locking mechanism for secure connection between the quick-change master and adapter / Manual emergency unlocking possible no counter-forces from springs / All functional components made from hardened steel for high mechanical resilience of the changing system / The same feed-through modules for all sizes that permits the use of standard parts in the production line / Possibility of transmission of electric media for a safe power supply of the handling modules and tools / As standard, many feed-through modules can be attached for highest flexibility of your application / Adapter side coding via plug connector possible / Suitable storage racks for all sizes to ensure the optimum adaption to each application / ISO mounting pattern for easy assembly to most types of robots without needing additional adapter plates |

SWS-L Downloads

IM0018188

You need to

register

to download this file.