Vansichen SVP-V Specifications

Ranked Nr. 82 of 98 Robot Accessories

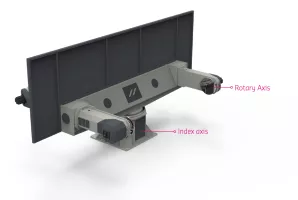

The SVP-V is a highly efficient and reliable single axis turn table positioner that can handle heavy payloads up to 30,000 kg. This positioner is specifically designed for heavy-duty applications and is suitable for large diameter workpieces. It is also available in an extra high accuracy version for machining type applications.

The SVP-V is constructed with a high strength welded steel structure, providing the necessary rigidity for the heavy payloads it can handle. Additionally, the design of the positioner ensures that it can be manufactured at a low cost, enabling Vansichen to offer a competitively priced product to customers.

Vansichen uses state-of-the-art reduction gearboxes, X bearings, and gear solutions in the construction of the SVP-V, ensuring its reliability and high performance. The positioner also comes with several available options to meet specific customer needs. These options include a ground bushing with sliding copper blocks, a swivel unit for air and signals, an extra high accuracy version, a home/safe position sensor, servo motor integration, and a special color of paint.

Customers can rest assured that the SVP-V comes with the same level of quality and attention to detail as all of Vansichen's products. All products come with CE-conform documentation, and customers can request drawings in 2D and 3D format, as well as all descriptions and maintenance schedules.

In addition to offering high-quality products, Vansichen provides professional on-site assembly and complete service. The company also offers customers the option to start up their system at Vansichen's premises. These services ensure that customers can trust Vansichen to provide a complete solution for their automation needs, from design to installation and beyond.