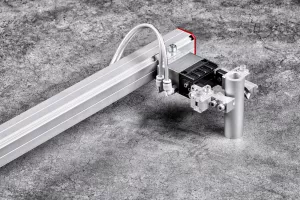

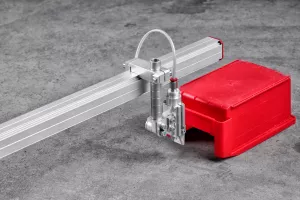

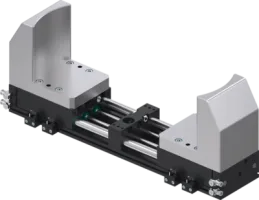

VersaBuilt MultiGrip Gripper Specifications

Ranked Nr. 503 of 235 Grippers

| Operation type |

|

| Energy source |

|

| Extra info | Eliminates the need to duplicate part workholding for both the robot gripper and CNC Allows machinist to easily create optimal part workholding in the CNC Supports more complex part shapes than traditional robot part grippers Simplified Op 1 to Op 2 part transfer Easier new part integration to the automation system Faster part change-over Increased automation reliability |

MultiGrip Gripper Downloads

Multi Grip Gripper Datasheet

You need to

register

to download this file.