Polishing and grinding cobots are smart robots making polishing and grinding applications smoother, safer, and way more efficient. Plus, they’re all about keeping your team safe and cutting down on costs. In a nutshell, cobot polishing and grinding are your ticket to upping your production line’s game without the headache.

Let’s dive into the top 10 benefits they bring to the table.

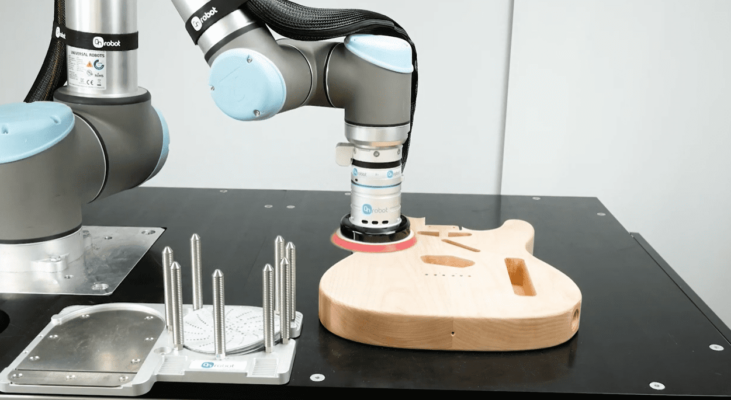

Understanding Cobots:

Cobots are robots that work safely next to you and your team. You don’t have to worry about them; they’re designed to be aware of people around them and stop or slow down to keep everyone safe.

These robots are incredibly adaptable. They can switch from polishing to grinding in no time, making them a versatile addition to your workspace. Plus, you won’t need a tech degree to use them. Setting them up and getting them to start working is straightforward.

Cobots are also big time and money savers. They handle the repetitive tasks, freeing up your team to do the work that requires a human touch. This not only speeds up your production line but also makes your workplace a better place to be.

The Importance of Polishing and Grinding:

Polishing and Grinding: Why It Matters

Every Detail Counts:

In manufacturing, the final look of your product is everything. Polishing and grinding makes sure your products shine and feel smooth to the touch. This isn’t just about looking good; it’s about making products that your customers can trust.

Long-Lasting Products:

A well-polished and ground product doesn’t just catch the eye; it lasts longer too. These processes remove imperfections and prevent damage that can happen over time. It’s like giving your product a protective shield, making sure it stands the test of time.

Efficiency is Key:

Polishing and grinding are not just about the end product. They also make your manufacturing process more efficient. By smoothing out rough edges, your products are easier to assemble, paint, and finish. This means you can produce more high-quality products in less time.

Why You Should Care:

Customer Satisfaction:

When your products look and feel high-quality, your customers notice. A smooth, polished finish makes your product stand out. It’s a sign of quality and care, something customers are willing to pay a premium for.

Standing Out:

In a crowded market, every little detail can set you apart from the competition. Polishing and grinding are your secret weapons. They transform your products from good to exceptional, giving you an edge over others.

Saving Costs in the Long Run:

Investing time in polishing and grinding can save you money down the line. Products that last longer mean happier customers and fewer returns. Plus, efficient processes reduce waste and speed up production, cutting costs and boosting your bottom line.

Which Industry Utilise Cobots for Polishing & Grinding Applications:

In many factories, cobots are now doing jobs that were once done by people. This change has brought many benefits. Cobots don’t get tired, and they can do the same task many times without making mistakes.

For Your Car:

In car making, cobots are a big deal. They polish and grind car parts, making sure everything from the body to the smallest knob looks great and works well. They’re why your car looks shiny and new.

Metal Works:

If you’re in metal manufacturing, cobots are your go-to. They smooth out metal pieces, making them look good and fit just right. This is how tools, machines, and even kitchen sinks end up looking flawless.

Furniture Making:

Cobots also help make furniture. They work on wood and metal, ensuring your chairs, tables, and lamps are not just strong but also nice to look at. It’s all about that smooth finish and polished look.

Aerospace:

For those building planes or space gear, precision is everything. Cobots help by polishing and grinding parts to perfection. They make sure everything from engines to door handles can handle the skies and beyond.

Electronics:

In electronics manufacturing, cobots keep things neat. They polish phone cases and smooth out computer parts, making sure your gadgets are not just cool but also comfortable to hold and use.

10 Benefits of Using Cobot Polishing & Grinding:

1. Very Precise & Consistent:

Cobots are your go-to for tasks where there’s no room for error. In polishing and grinding, even a tiny mistake can ruin a product’s look or how well it works. Cobots get it right every time. They’re built to do the same job again and again without slipping up or getting tired, unlike us humans who might make a mistake if we’re tired or just having an off day. This makes cobots super reliable for those jobs where every detail has to be perfect.

2. They Can Do Many Different Jobs:

Cobots are real game-changers, especially in factories where versatility is key. They’re not stuck doing just one job; you can quickly switch them from polishing car parts to working on airplane components without a fuss. Need to shake things up and start making something new? Cobots can adapt to new tasks fast, making them perfect for both big and small businesses. Whether you’re handling tiny gadgets or large machinery, cobots can be adjusted to fit the job, offering a helping hand no matter the size of your project.

3: Safe to Work With:

Safety in factories is a big deal, and that’s where cobots come in. They’re built with safety in mind, equipped with sensors that help them work closely with people without any accidents. Cobots can take on the risky jobs, dealing with things that are too hot, sharp, or heavy, which reduces the chances of injuries at work. This allows you and your team to focus on the more complex tasks, with cobots handling the repetitive work.

4: Cost-Effective and Efficient:

Using cobots in your factory can help you save money and increase efficiency in several ways. Firstly, cobots can operate continuously, day and night, allowing them to complete tasks more quickly than human workers, which reduces the need for additional staffing and saves on labor costs. Secondly, their precision means they make fewer errors, leading to less waste of materials and further cost savings. Lastly, cobots are designed to be user-friendly and require minimal adjustments to your existing setup, allowing for a swift and efficient integration into your production line. This makes them an economically smart choice for boosting your factory’s performance.

5: Easy of Use:

Integrating cobots into your workplace is easy and hassle-free. Their design is user-friendly, allowing your workers to quickly learn how to program them with minimal training needed. This not only simplifies your daily operations but also lowers stress levels among your team. Moreover, cobots are highly adaptable and can be introduced into various work environments without the need for significant alterations. This flexibility makes it straightforward for your business to adopt cobot technology, enhancing efficiency without the complexity.

6. Increased Productivity:

Cobots enable you to accomplish more work in less time, boosting your productivity significantly. They can operate around the clock without breaks, allowing for a higher output compared to human workers, which means you can produce more goods quicker. Since cobots maintain a constant speed without slowing down or getting tired, you’re guaranteed a steady flow of work. Furthermore, their ability to quickly handle tasks such as polishing and grinding speeds up the entire production process, making it more efficient.

7: Quality Control:

Cobots excel in ensuring your products are made with top-notch quality. They perform tasks like polishing and grinding with incredible precision, significantly reducing errors and boosting the overall quality of your products. Because of their accuracy, the quality of work cobots produce is consistently high, ensuring all your products meet your strict standards. Additionally, cobots can be outfitted with sensors that monitor the quality of work in real-time, allowing for immediate detection and correction of any issues.

8: Improved Working Environment:

Cobots make your workplace better and safer in several ways. They take on the tough, repetitive tasks, cutting down on the physical strain for human workers, which lowers the risk of injuries and fatigue. When cobots work side by side with your team, they help foster a collaborative atmosphere, making employees feel more connected and less isolated. Additionally, thanks to their precise movements and safety features, cobots help to significantly reduce workplace accidents by handling the more hazardous jobs.

9: Skill Development:

Working with cobots not only enhances your production line but also helps your employees develop new and valuable skills. By learning to program and operate cobots, they gain technical skills crucial for today’s manufacturing world. This experience also sharpens their problem-solving abilities as they find ways to optimize processes with cobot assistance. Additionally, the flexible nature of cobots teaches employees to quickly adapt to new technologies and methods, making them more versatile and valuable in any industry.

10. Future-Proofing Your Business:

Incorporating cobots into your business keeps you at the forefront of technology, ensuring you stay competitive. Cobots offer the flexibility to scale your operations smoothly, allowing you to adjust and expand according to market demands without significant investment. They also prepare your business for future technological shifts and evolving market needs, securing your relevance and success in the long term.

Conclusion:

Cobots are transforming the way we handle polishing and grinding tasks, making these processes more precise, safer, and cost-effective. By integrating cobots into your operations, you can achieve higher quality products, enhance workplace safety, and enjoy significant savings. These robots are not just tools; they are your partners in streamlining production and fostering a culture of innovation and collaboration. With their help, you can not only improve your current processes but also prepare your business for future challenges and opportunities. If you’re looking to take your manufacturing to the next level, exploring cobot technology could be the key to unlocking new potentials and staying competitive in today’s market.

Do You Need to Compare Different Polishing & Grinding Cobots?