3D vision technology will transform your production line. It’s about turning cameras and sensors into the eyes for your machines, allowing them to see and understand depth. With this tech, your robots can measure, recognize, and handle objects on their own. It’s transforming how work gets done by making machines smarter and tasks faster. If you’re looking to boost your manufacturing efficiency, getting to know 3D vision is key.

Let’s explore how this technology can be a crucial asset for your business.

What Are 3D Vision Systems?

3D vision systems let your machines see the world like you do, in three dimensions. They give robots the ability to spot, measure, and recognize objects, transforming how tasks are done in your factory.

How They Work?

Capturing the Scene

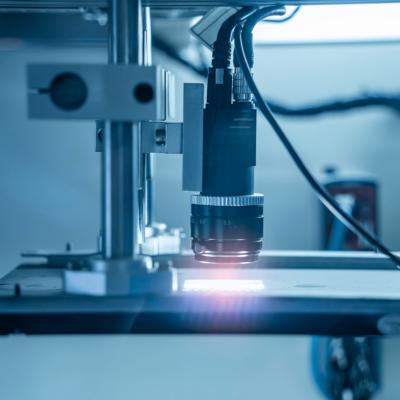

These systems start by taking a good look around. Using special cameras or lasers, they grab images or scans from different angles. This is like gathering puzzle pieces to see the whole picture.

Making a 3D Model

With those pieces, the system builds a 3D model. This model is a digital version of the object, showing its height, width, and depth. It’s like having a mini, virtual copy of the real thing.

Understanding the Object

Next, the system uses this model to figure things out. What’s the object? Where’s it located? The system processes this info, readying robots for action.

Action Time for Robots

Armed with this knowledge, robots get to work. They can pick, place, and inspect items with incredible accuracy. This is all about letting your robots handle tasks smarter and safer.

Why It’s a Big Deal?

3D vision boosts your line’s speed and cuts down on errors. Plus, it can take on dangerous jobs, keeping people safe. By adding 3D vision to your setup, you’re setting your business up for more success, making sure every task is done just right.

The Core of 3D Vision Applications:

3D vision technology isn’t just fancy; it’s a versatile tool that’s reshaping how industries operate. From making cars to packing your favorite snacks, 3D vision helps ensure everything is done just right.

1. Quality Control and Inspection:

Spotting the Imperfect

In manufacturing, even a tiny error can be a big deal. 3D vision systems are like the ultimate quality checkers. They can spot defects you might not see with your eyes, checking the size, shape, and even the texture of products. This means they can catch a scratch on a car part or a dent in a metal sheet before it becomes a problem.

Measuring Up

Accuracy is everything. 3D vision systems measure objects down to the millimeter, ensuring each product meets strict standards. Whether it’s a plastic bottle or an engine part, these systems make sure every item is just the right size and shape.

Seeing the Difference

Some defects are hard to spot, especially on complex surfaces. 3D vision excels here, distinguishing between normal variations and true flaws. It’s like having a super-powered inspector that never gets tired or misses a detail.

Final Check

Before products ship out, 3D vision gives them one last look-over. This final inspection ensures that only the best products make it to customers, helping maintain your reputation for quality.

2. Robotic Guidance and Automation:

Smart Robots, Smarter Workflows

In the heart of your factory, robots are the heavy lifters. But with 3D vision, they become brainy too. This technology guides them to pick, place, and even assemble parts with precision. It gives your robots a map and a set of eyes, so they know exactly where to go and what to do.

Precision in Every Move

Imagine robots that can select the right tool for a job or adjust their grip on objects of all shapes and sizes. That’s what 3D vision brings to the table. It allows robots to identify the best approach for handling materials, ensuring they do it right the first time.

Adapting on the Move

Your production line is always changing, and 3D vision helps robots keep up. They can adapt to new tasks quickly, whether it’s assembling a new product or packing items differently. This flexibility means you can switch things up without slowing down.

Collaborating Safely

Safety is a top priority, especially when robots and humans work side by side. 3D vision systems ensure robots know where their human coworkers are, avoiding accidents and creating a safer workplace. It’s about making sure everyone — machines and people — can work together harmoniously.

3. Logistics and Material Handling:

Streamlining the Supply Chain

In warehouses and distribution centers, 3D vision technology keeps everything moving smoothly, from the arrival of raw materials to the shipping of final products. By guiding robots to sort, stack, and transport goods, 3D vision ensures that every item is in the right place at the right time.

Speed and Accuracy Combined

Mistakes in logistics can be costly. 3D vision reduces these errors by giving robots the ability to recognize and handle items with unmatched precision. Whether it’s placing a fragile item on a high shelf or sorting packages by size and destination, these systems make sure it’s done quickly and correctly.

Adapting to Change

Every day brings a new challenge in logistics. With 3D vision, robots can adjust to changing demands without missing a beat. They can switch from handling bulky boxes to delicate parcels in an instant, making your operations more flexible and responsive.

A Safer Workplace

Safety is crucial, especially in fast-paced environments. 3D vision helps prevent accidents by ensuring robots are aware of their surroundings, including people moving around them. This technology creates a safer workspace, where humans and machines work together without stepping on each other’s toes.

4. Advanced Applications:

Autonomous Vehicles

Autonomous vehicles are more than just cars that drive themselves. They’re about creating a safer, more efficient way to travel. 3D vision is at the heart of this innovation, helping vehicles understand and navigate their environment. By accurately identifying obstacles, other vehicles, and pedestrians, 3D vision systems ensure these futuristic cars can make decisions in real-time, promising a revolution in how we move from place to place.

Drone Navigation

Drones are taking to the skies for everything from delivery services to emergency response. With 3D vision, drones can fly more safely and efficiently, avoiding obstacles and navigating complex environments. This technology allows them to accurately deliver packages, even in crowded urban areas, and provide critical support during natural disasters without putting human lives at risk.

Medical Imaging

In healthcare, 3D vision is opening new doors for diagnosis and treatment. By providing detailed three-dimensional images of the human body, doctors can detect and understand medical conditions more accurately than ever before. This insight is crucial for planning surgeries, monitoring diseases, and offering personalized care, making medicine more effective and less invasive.

5. Security and Surveillance:

Making Spaces Safer

With 3D vision, you’re bringing a new level of safety to your space. These systems don’t just watch; they understand depth and movement, offering a clearer picture of what’s happening around you. Whether it’s a busy mall or a private facility, 3D vision helps keep an eye out for anything out of the ordinary.

Seeing More Than Before

Ever wonder how security misses something right in front of it? That’s often because traditional cameras lack depth. 3D vision changes that by giving security teams the ability to see and measure distances, sizes, and movements in real-time. This means being able to tell if someone is just hanging around or if an object shouldn’t be there.

Stopping Trouble Before It Starts

What if you could stop an incident before it even happens? 3D vision gives you that power. By understanding the usual flow of people and objects, these systems can spot when something doesn’t fit the pattern. It’s about keeping your place safe by catching risks early.

Smarter with AI

Pair 3D vision with AI, and you’ve got a smart security guard that gets better over time. AI learns from everything 3D vision sees, improving how it spots and responds to potential threats. This combination means faster, more accurate decisions to keep everyone safe.

Conclusion:

3D vision technology is changing the game across industries, from manufacturing to security. It’s making processes smarter, safer, and more efficient. If you want to stay ahead, now’s the time to get on board with 3D vision. It’s not just an upgrade; it’s a way to transform how you work, ensuring you remain competitive and innovative.

Do You Want to Compare Different 3D Vision Systems?