Sanding is tough. It’s repetitive, dusty, and hard on your body. Finding workers for the job is getting harder. But what if you didn’t have to?

AI-powered robots can take over sanding for you. They work faster, create less dust, and deliver consistent results. Performance Composites, a manufacturer like you, made the switch. They now have cleaner air, better quality, and trained robot operators in just one day.

In this blog, you’ll understand how AI and robotics can solve your sanding challenges—helping you work smarter, not harder.

How AI-Powered Sanding Robots Work:

AI-powered sanding robots are built for high-volume, industrial production. They handle repetitive, labor-intensive sanding tasks with speed and precision, reducing costs and improving efficiency. These robots operate autonomously in dedicated work areas, ensuring consistent results across large batches.

Smart Vision & Automated Programming:

Unlike traditional robots, AI-powered sanding robots don’t need complex programming. They use 3D vision and AI to scan each part, map its shape, and determine the best sanding approach. This eliminates the need for expensive fixtures or lengthy setups—making them ideal for mass production.

High-Speed, High-Precision Performance:

These robots apply consistent pressure, work in wet or dry environments, and handle large, complex parts with ease. They eliminate up to 95% of sanding dust, creating a safer factory environment.

Best for Large-Scale Automation:

If you need a fully automated sanding process that runs independently for long hours, AI-powered robots are your best option. They maximize efficiency, reduce waste, and improve surface quality at an industrial scale.

How an AI-Powered Cobot Sands with Precision:

AI-powered sanding cobots are designed for flexibility and human collaboration. They work alongside your team, automating sanding without requiring a major workflow change. Unlike industrial robots, cobots are easier to deployand operate in shared spaces.

Scans & Learns Instantly:

Cobots use 3D vision and AI to scan parts, recognize shapes, and generate sanding paths—without complex programming. This makes them perfect for low- to mid-volume production, where parts frequently change.

Adapts in Real Time:

Unlike traditional automation, cobots adjust on the fly. They apply the right sanding force, detect material differences, and follow precise movements to ensure a flawless finish. Whether you’re sanding small, delicate parts or large, irregular surfaces, cobots adapt with ease.

Safe & Easy to Use:

Cobots are designed to work safely with people. They reduce dust exposure, minimize repetitive strain injuries, and create a cleaner, healthier workspace. Training your team to operate a cobot takes just one day, making automation more accessible.

Best for Flexible, Human-Friendly Automation:

If you need automation that integrates seamlessly into your existing process, AI-powered cobots are the way to go. They’re ideal for high-mix, low-volume production and companies looking for a cost-effective, easy-to-use sanding solution.

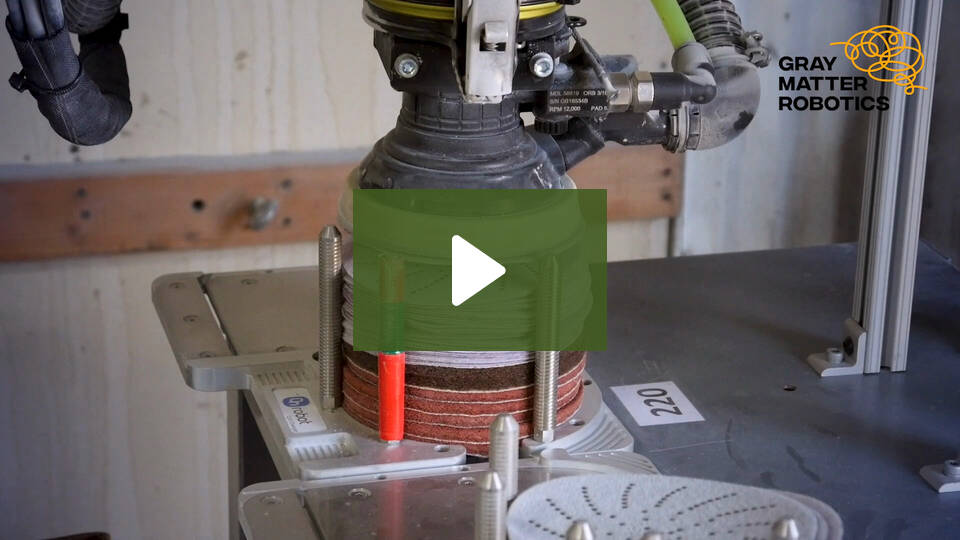

This video showcases the Robotiq Sanding Kit integrated with a Universal Robot, demonstrating its automated sanding capabilities for efficient and consistent surface finishing.

Traditional Sanding vs. AI-Powered Robotic Sanding:

| Features | Traditional Sanding | AI-Powered Robotic Sanding |

| Labor Requirement | Requires skilled workers for consistent results | Automates sanding, reducing the need for manual labor |

| Consistency | Quality varies due to human fatigue and skill | Delivers uniform sanding with precise control |

| Speed & Efficiency | Slower, depends on worker stamina | Works faster with optimized sanding paths |

| Dust Control | High dust generation, health risk for workers | Eliminates up to 95% of dust, improving air quality |

| Adaptability | Limited; requires manual adjustments for different parts | Uses AI to adjust to various shapes, sizes, and materials |

| Setup & Programming | Requires jigs, fixtures, and manual expertise | Self-programs using 3D vision and AI |

| Work Environment | Can be physically demanding and hazardous | Reduces strain on workers, improving workplace safety |

| Operating Cost | High labor and material costs due to waste and inefficiency | Reduces material waste and labor expenses |

| Training Time | Workers need experience to master sanding | Operators can learn to use robots in a day |

The Case of Performance Composites:

A Leader in Composite Manufacturing:

Performance Composites, Inc. specializes in manufacturing composite parts for the transportation industry, supplying high-quality components for various applications. As demand grew, they faced a common industry challenge—keeping up with production while maintaining consistency and quality.

The Challenge: Labor Shortages & Automation Hesitation

Sanding is a critical yet demanding part of their production process. Finding skilled workers for this repetitive, dusty task became increasingly difficult. High turnover and labor shortages made it hard to maintain efficiency.

While automation seemed like a solution, Performance Composites was concerned about the complexity of robotic sanding. Traditional automation required extensive programming, expensive fixtures, and long setup times—barriers that made manufacturers hesitant to switch.

To stay competitive, they needed a smarter, easier-to-use solution that could deliver consistent quality without disrupting operations.

Adoption of AI-Powered Robotic Solutions:

Partnering with GrayMatter Robotics:

To overcome labor shortages and improve efficiency, Performance Composites turned to GrayMatter Robotics, a leader in AI-driven automation. Specializing in smart robotic solutions, GrayMatter Robotics develops intelligent systems that self-program and adapt in real time, making automation more accessible for manufacturers of all sizes.

The Solution: AI + Cobot Precision:

GrayMatter Robotics deployed GMR-AI technology with a FANUC CRX-10iA/L, creating a fully automated sanding system. This solution combined advanced 3D vision and AI-powered adaptability, allowing the cobot to scan parts, determine the optimal sanding path, and execute precise movements—all without complex programming.

Unlike traditional robots, this system self-adjusts to different materials, shapes, and surface conditions in real time. It eliminated the need for costly fixtures and lengthy setups, making automation faster, smarter, and easier to deploy.

By integrating AI-powered robotic sanding, Performance Composites streamlined production, improved consistency, and created a safer, cleaner work environment—all while training operators in just one day.

The video by GrayMatter Robotics showcases the Fanuc CRX robotic system performing automated sanding using advanced scanning technology.

Benefits Realized:

Cleaner Air, Safer Workplace:

Manual sanding generates large amounts of dust, creating health risks for workers and requiring extensive cleanup. With the AI-powered FANUC CRX-10iA/L, Performance Composites reduced dust by 90-95%, dramatically improving air quality. The automated system kept dust contained at the source, creating a cleaner, safer environment for employees.

Fast, Simple Training:

Automation can seem complex, but with AI-driven technology, it doesn’t have to be. Performance Composites’ employees learned to operate the sanding cobot in just one day—no advanced programming skills required. The system’s intuitive AI and self-programming capabilities made it easy for operators to set up and run, removing barriers to adoption.

Consistent, High-Quality Finishing:

Sanding quality often varies due to worker fatigue and skill differences. With AI-powered automation, Performance Composites achieved consistent, precise sanding on every part. The cobot applied uniform pressure, followed optimized sanding paths, and adjusted in real time, ensuring a flawless finish across all components.

By automating sanding, Performance Composites improved efficiency, quality, and workplace safety—while empowering their team with cutting-edge technology.

To learn more about this case study, check out the video:

CRX Cobot & AI Solve Sanding Challenges for Performance Composites

Key Features of the Robotic System:

AI-Powered Self-Programming:

Traditional robots require complex programming and setup. The GMR-AI system eliminates this hassle by self-programming in real time. Using 3D vision and AI, the robotic system scans each part, maps its surface, and determines the optimal sanding path—no manual coding or expensive fixtures needed.

Handles Large & Complex Parts:

Manufacturers often work with varied part sizes and intricate geometries. The FANUC CRX-10iA/L, powered by GMR-AI, can sand large and complex components with precision. It applies the right force, follows detailed contours, and ensures consistent surface finishing, even on irregular shapes.

Versatile Across Materials & Applications:

Whether sanding fiberglass, composites, plastics, or metals, this system delivers smooth, high-quality results. Its AI-driven adaptability makes it suitable for a wide range of sanding and polishing tasks, enhancing productivity across different applications.

Adapts to New Materials & Reduces Waste:

The system automatically adjusts to new materials, optimizing sanding parameters without requiring manual intervention. This minimizes material waste, extends the life of sanding tools, and reduces overall consumable costs, making production more efficient and cost-effective.

Broader Implications for Manufacturing:

Solving Labor Shortages & Enhancing Workplace Safety:

Finding skilled workers for manual sanding is a growing challenge. AI-powered robotics bridge the labor gap by automating repetitive, physically demanding tasks. This allows manufacturers to reallocate workers to higher-value roles while reducing injuries from prolonged exposure to dust and vibration. A safer, healthier work environment leads to higher job satisfaction and retention.

Scaling Production with Greater Flexibility:

Traditional automation often requires fixed setups and extensive programming, making it difficult to adapt to changing production needs. AI-powered sanding systems provide built-in flexibility, allowing manufacturers to scale production up or down without complex reconfigurations. Whether handling high-volume batches or custom, low-volume orders, these robots seamlessly integrate into existing workflows.

Consistent Quality, Less Rework:

Variability in manual sanding leads to inconsistent finishes and costly rework. AI-powered robots deliver precision and repeatability, ensuring uniform surface quality across every part. By eliminating human fatigue and skill variation, manufacturers achieve higher first-pass yields, reduced scrap, and improved overall efficiency.

By adopting AI-powered sanding, manufacturers can increase output, enhance product quality, and future-proof operations—all while creating a cleaner, more efficient workplace.

Conclusion:

AI-powered robotic sanding eliminates dust, improves consistency, and solves labor shortages—helping you work smarter, not harder. Performance Composites made the switch and now enjoys cleaner air, flawless finishes, and trained robot operators in just one day. With self-programming AI, real-time adjustments, and precise sanding paths, these robots take the complexity out of automation. Whether you need high-speed production or a flexible, human-friendly solution, AI-driven sanding boosts efficiency and quality while keeping your team safe. The future of sanding is here—faster, cleaner, and easier. Are you ready to make the change?

References:

- FANUC America. (n.d.). Performance Composites: AI and Robotics Solve Sanding Challenges. Retrieved on 7th February 2025, from https://www.fanucamerica.com/case-studies/performance-composites