If you work with projects and are new to CNC machines, you might be curious about how these high-tech tools can help your manufacturing. In this guide, we’ll explore the top 10 practical uses of CNC machines in a simple and easy-to-understand way.

We’ll break down these game-changing technologies, making it simple for you to grasp and use them in your projects.

What is a CNC Machine?

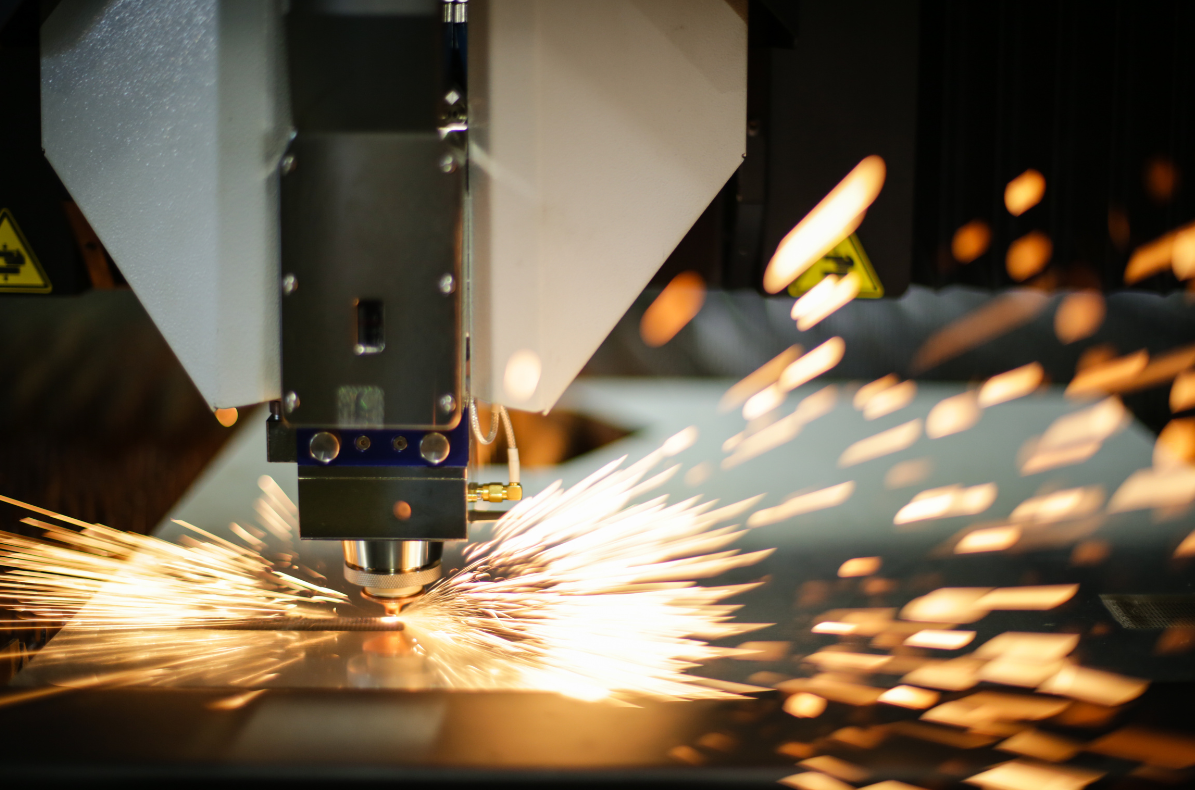

A CNC machine is a smart tool that follows computer instructions to do tasks with great accuracy. It can cut, shape, and make things exactly as planned. Unlike older machines operated by people, CNC machines work by themselves, making manufacturing more efficient and error-free.

10 Common Materials Suitable for CNC Machining:

CNC machines are versatile and can work with many different materials. The type of material used depends on the job, but here are some common ones:

1. Metals:

CNC machines can cut and shape metals like aluminum, steel, and brass. These metals are used in things like cars and planes.

2. Plastics:

CNC machines also work with plastics, like acrylic and PVC. These are used in signs and electronics.

3. Wood:

For woodworking, CNC routers handle wood materials such as hardwoods and plywood.

4. Composite Materials:

In aerospace and marine industries, CNC machines work with materials like fiberglass and carbon fiber, which are strong and lightweight.

5. Foam:

CNC machines can cut foam, used for packaging and insulation.

6. Stone:

CNC machines can engrave or carve stone, used for monuments and countertops.

7. Glass:

For artistic designs on glass, CNC machines are used for engraving and cutting.

8. Ceramics:

In electronics and advanced ceramics manufacturing, CNC machines can precisely shape ceramics.

9. Textiles:

CNC machines cut textiles for making clothes and upholstery.

10. Rubber:

CNC machines cut and shape rubber for gaskets and seals.

CNC machines are flexible and can be adjusted to work with different materials, making them helpful tools in various industries.

10 CNC Machine Applications:

Now, let’s delve into the top 10 practical applications of CNC machines in straightforward terms.

1. Precision Cutting:

CNC machines are incredibly good at cutting things very accurately. This makes them super important in factories and workshops. They can cut materials like metal, plastic, and wood very precisely, ensuring that the things made are of high quality and fit together perfectly. Think of it as a master cutter that never goes wrong.

2. Automated Milling:

With CNC machines, milling becomes much easier. The machine does it all by itself, so the results are always the same, with very few mistakes. Whether you need to make a few prototypes or a lot of parts, CNC milling helps you get the job done faster and better. It’s like having a skilled helper in your workshop.

3. Drilling:

CNC machines are experts at making holes with great precision. Whether you need simple holes or more complicated patterns, the machine can do it all automatically. This saves time and resources, making your work more efficient. Imagine it as a super-precise hole maker.

4. Customized 3D Engraving:

CNC machines can create detailed 3D engravings. This means you can personalize your products, add logos, or make unique designs easily. This ability allows you to make your products special and stand out from the rest. It’s like having an artist that can etch designs on anything you want.

5. High-Speed Routing:

CNC routers are a big help in factories. They work quickly and can do tasks like cutting, shaping, and engraving at high speeds. This boosts overall productivity and helps products get made faster. Think of them as speedy workers that never get tired.

6. Prototyping Made Simple:

Making prototypes is an important step when developing new products. CNC machines let you turn your design ideas into real prototypes fast. This speeds up testing and helps you improve your designs more effectively. It’s like having a magic machine that turns your ideas into real things in no time.

7. Automated Welding:

Adding CNC machines to welding tasks makes things smoother. The machine does the welding very precisely, so there are fewer mistakes. This improves the quality of welded items and saves time. Think of it as a super-precise welder that never misses a spot.

8. Intricate Textile Production:

CNC machines aren’t just for metal and plastic. They’re great with fabrics too. Whether you need to cut complex patterns or make custom clothes, CNC machines bring precision to textile work. It’s like having a master tailor that can cut and sew fabrics with amazing accuracy.

9. Woodworking:

For those who work with wood, CNC machines are a blessing. They cut, carve, and shape wood with incredible precision. Whether you’re making furniture or detailed wooden designs, CNC technology makes woodworking projects much better. Think of it as having a woodworker with the steadiest hands in the world.

10. Medical Component Manufacturing:

In the medical field, everything must be precise. CNC machines play a big role in making detailed parts for medical devices. This ensures that medical equipment is of the highest quality, which is crucial for healthcare. It’s like having a medical instrument maker who never makes mistakes.

Conclusion:

In conclusion, CNC machines are versatile and important tools in various industries. They excel at tasks like cutting and milling, making them valuable for producing high-quality items. When you use CNC technology in your work, you’re not just keeping up with others – you’re making your work better and more accurate, which is a big step forward. These machines are like skilled workers that never get tired and always do a perfect job. So, if you’re looking to improve your manufacturing, CNC machines are the way to go.

To learn more about CNC Machines.

Are You Looking For A Systems Integrator?

Visit Qviro'