In manufacturing and engineering, CNC machines have changed how we make detailed and accurate parts. These machines use computers to control cutting tools, making production precise and efficient. This article will look at 12 types of CNC machines that are crucial in different industries.

But before we begin,

What is a CNC Machine?

A CNC (Computer Numerical Control) machine is a fancy tool used in making stuff like metal or wood parts. It works by following computer instructions to cut or shape the material. The machine has a brain called a controller that reads the instructions and tells the tools where to move. This makes the cutting really accurate.

CNC machines are used in many industries to make things with lots of details. They’re good because they do the job the same way every time, making less mistakes. This helps in making things quickly and precisely. So, CNC machines are like smart workers in factories.

Here are the 12 main types of CNC machines:

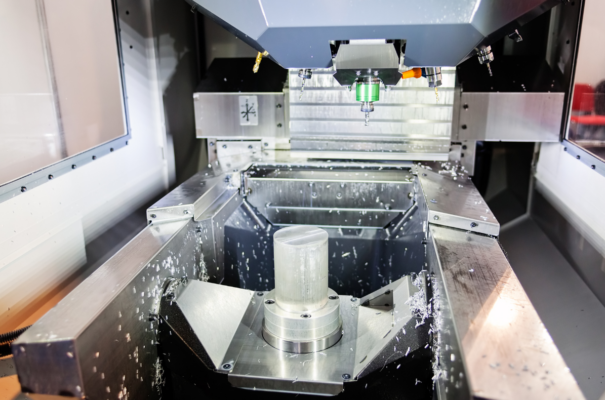

1. CNC Mills:

CNC mills are special machines used in making things. They cut, shape, and finish materials like metal. These machines are like smart workers because they follow computer instructions to do the job very accurately. They use different tools for cutting, such as end mills and drills, which have specific jobs. Industries, like car-making and aerospace, use CNC mills a lot to make precise and complex parts.

Here’s how they work: First, the material is secured, and then the computer controls the milling tool to move and cut. This makes the final shape needed for the part. CNC mills are very important in modern manufacturing because they make things with lots of details. As technology gets better, these machines continue to improve, making them even more useful in making complex and accurate parts.

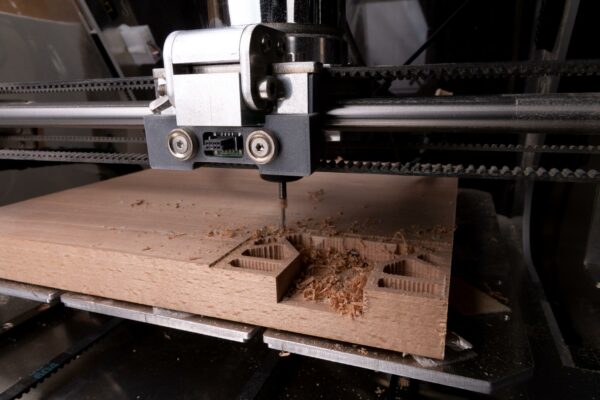

2. CNC Routers:

CNC routers are machines that are quite handy for cutting and shaping materials like wood and plastic. These machines have a spinning tool that moves in various directions to make detailed designs. They are super important in woodworking, sign-making, and creating prototypes.

Here’s how they work: The spinning tool follows instructions from a computer to cut and shape materials precisely. CNC routers are crucial for achieving accurate designs and models.

3. CNC Plasma Cutting Machines:

CNC plasma cutting machines are essential tools in manufacturing. They use a speedy jet of gas to cut through materials like steel. This is especially important in creating precise metal cuts required in industries like car manufacturing.

Here’s how they work: The machine guides a high-speed jet of gas to cut through materials that conduct electricity, such as steel. This produces precise shapes needed for various parts. CNC plasma cutting machines play a significant role in manufacturing items with metal in various industries.

4. CNC Lathes:

CNC lathes are machines employed for shaping materials. They operate by spinning the material against a cutting tool. This is quite important, especially when making cylindrical or conical parts required in industries like aerospace and medical manufacturing.

Here’s how they work: The material rotates, and a cutting tool shapes it. CNC lathes are essential for turning operations, creating parts with precision. Industries like aerospace heavily rely on these machines for producing accurate and complex components.

5. CNC Laser Cutters:

CNC laser cutters are machines that use lasers for precise material cutting. They find use in industries that need delicate cuts, such as crafting jewellery and electronic components.

Here’s how they work: The machine directs a laser beam to cut materials accurately. CNC laser cutters are critical in achieving precise cuts for intricate parts across various industries.

6. CNC Water-jet Cutters:

CNC water-jet cutters are machines that use a strong stream of water with particles to cut through materials. They are versatile and can cut a wide range of materials, including metal, glass, and stone.

Here’s how they work: The machine pushes powerful water along with small, rough particles, and it uses this mix to slice through things. What’s really neat is that these CNC water-jet cutters can cut different things with ease because they are good at adjusting to what they’re cutting.

Think of it like a powerful water hose with sand that carves shapes into different materials. It’s helpful for making precise cuts in all sorts of things like metal, glass, or stone. So, if you need to cut different materials accurately, CNC water-jet cutters are the way to go!

7. CNC Drilling Machines:

CNC drilling machines are essential for creating holes in materials with precision and efficiency. They are used in industries requiring accurate hole patterns, such as the aerospace and construction sectors.

Here’s how they work: These machines use electricity to remove tiny bits of material, making shapes with great accuracy. CNC EDM machines are vital in creating intricate shapes in industries where precision matters a lot. They can work with different metals and make things like car parts or airplane components.

8. CNC Electrical Discharge Machines (EDM):

CNC EDM machines are important tools used to shape materials accurately. They are used in industries that need precision, like making tools and molds.

Here’s how they work: The machine uses electrical discharges to shape materials accurately. CNC EDM machines are vital in achieving intricate shapes needed in industries where precision is crucial.

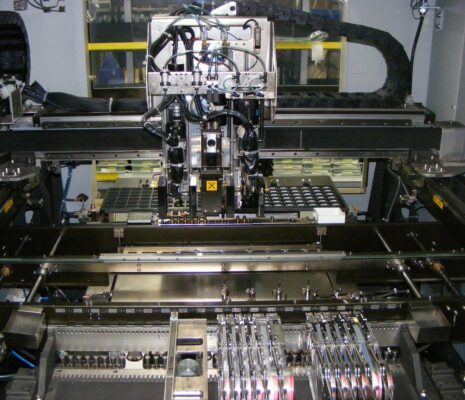

9. CNC Pick & Place Machines:

CNC Pick & Place Machines play a crucial role in the electronics industry. They help put electronic parts on printed circuit boards (PCBs), making it faster and more efficient to create electronic devices.

Here’s how they work: They carefully pick up electronic pieces and put them on the PCBs with precision. This process is essential for quickly and effectively producing electronic devices.

CNC Pick & Place Machines are used in factories that make things like phones, computers, and other gadgets. These machines speed up the work and make sure everything is put in the right place.

10. CNC 3D Printers:

CNC 3D printers are machines that build 3D objects one layer at a time using additive manufacturing. These machines have many uses, such as creating prototypes, making custom items, and even producing special implants for medical purposes.

Here’s how they work: The machine adds material layer by layer to form a 3D object. This process is changing the way things are made in different industries. It enables the production of unique and intricate parts tailored to specific needs.

11. CNC 2-Axis, 3-Axis, 4-Axis, & 5-Axis Machines:

CNC machines can move in different directions. The more directions they can move in, the more tasks they can handle. There are 2-axis machines that move in two directions, 3-axis machines in three directions, 4-axis in four, and 5-axis in five.

Let’s break it down:

1. 2-Axis CNC Machines: These can move in two ways, usually left-right and up-down. They’re good for basic jobs like making holes and simple cuts on flat things.

2. 3-Axis CNC Machines: These can move in three ways: left-right, up-down, and front-back. They’re used for more complicated tasks, like shaping objects in three dimensions.

3. 4-Axis CNC Machines: In addition to the three basic movements, they can also rotate things. Imagine spinning an object while shaping it. This is useful for tasks like engraving on a round surface.

4. 5-Axis CNC Machines: These can do everything the previous ones can, plus they can tilt or turn in two more ways. They’re the best for making very complex and precise things. Think of intricate shapes or parts used in industries like aerospace and medicine.

Here’s how they work: The number of axes means more in the number of directions a machine can move in affects how it works. More directions mean the machine can do more things and make more complex shapes. Machines with more directions are important for making intricate designs and shapes.

Conclusion:

CNC machines do lots of important jobs in different industries, like making things for airplanes and electronics. It’s crucial for manufacturers to know the various types of CNC machines and how they work to make things precisely, quickly, and flexibly. As technology gets better, we’ll see even cooler and more advanced CNC machines, making the manufacturing world more exciting. So, learning about CNC machines is like knowing the secrets of making things better in factories.

To learn more about CNC Machines.

Are You Looking For A Systems Integrator?

Visit Qviro'