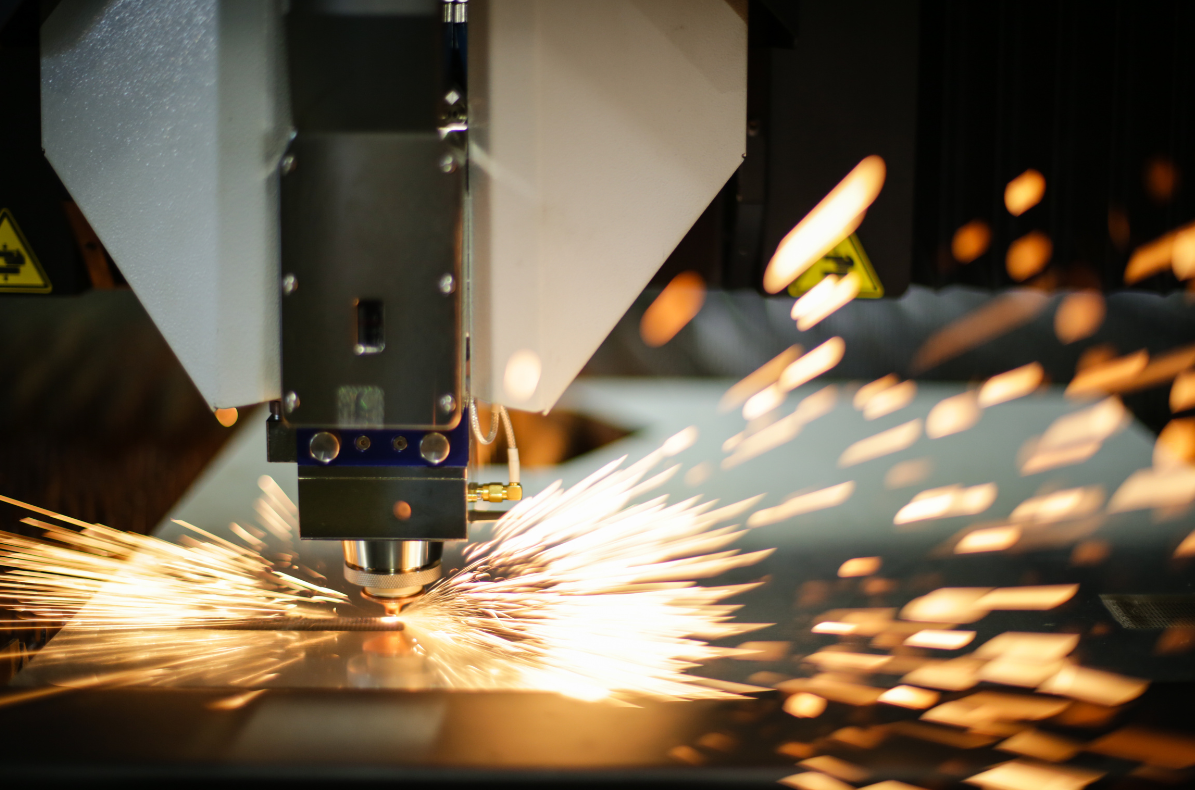

CNC programming is the key to automating manufacturing machines with precision. In this beginner’s guide, we’ll explore four types of CNC programming and what CNC machines are.

What is a CNC Machine?

CNC machines are automated tools used in manufacturing. They include milling machines, lathes, routers, or 3D printers. What makes them special is their ability to follow precise instructions, like a robot.

Instead of people manually controlling the machine, a computer guides it. This computer control ensures accurate and consistent cutting or shaping. CNC machines are crucial when precision and consistency matter.

For instance, in the automotive industry, CNC machines create engine parts with exact measurements to ensure a perfect fit. In aerospace, they make complex components like turbine blades. Even in smaller businesses like woodworking, CNC machines simplify the creation of detailed designs.

Now, let’s explore the different types of CNC programming.

1. Manual Programming:

“It’s simple for basic jobs and small-scale production, but you need to learn a specific language. This method is commonly used in jewelry making, woodworking, and custom manufacturing”

Manual programming is similar to giving directions to a robot using a special language. It’s used for simple tasks and small-scale production.

This method might be a bit challenging for beginners because it involves learning a specific language, like learning a new language. However, it’s valuable for making prototypes or custom items. It’s like using a map to provide step-by-step instructions to reach a destination.

Industries such as jewelry making, woodworking, and custom manufacturing still use manual programming. For example, a jewelry designer might use it to create precise metal designs. In woodworking, it’s used to make unique custom furniture pieces with exact measurements.

If you want to learn more about Manual Programming, this video is great in explaining it in full detail!

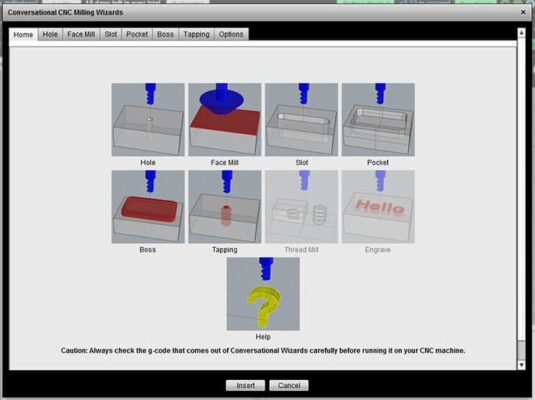

2. Conversational Programming:

“It’s beginner-friendly and perfect for simple tasks and quick setups. It’s used in job shops, small-scale manufacturing, and education,”

Conversational programming is easy to use. Instead of working with complicated codes, users talk to the machine using simple language.

This approach is great for beginners because it doesn’t need you to learn a specific programming language. It’s similar to having a conversation with a friend and explaining what you need.

Conversational programming is especially useful for setting up quickly and for smaller production runs. It might not be the best choice for very complicated tasks, but it works well for jobs that are relatively simple to moderately complex. Job shops, small-scale manufacturing, and educational institutions often prefer conversational programming because it’s easy and doesn’t take much time to set up.

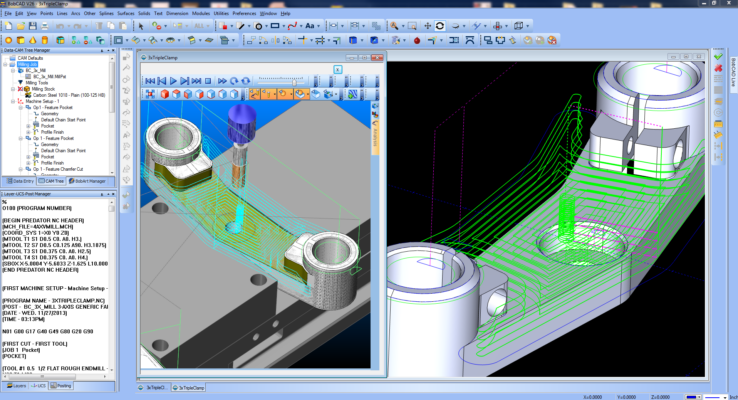

3. CAM Programming:

“Offers precision but requires learning. Common in aerospace, automotive, and medical device manufacturing for complex and precise parts.”

CAM, or Computer-Aided Manufacturing, is an important part of CNC programming. CAM programming uses computer software to help machines work without people having to do everything.

Think of it as having a smart helper who runs the machine very precisely – that’s what CAM programming is like. It makes sure the machine follows exact instructions without any mistakes from humans.

CAM programming is great for jobs that need to be very exact and the same every time. Industries like aerospace, car making, and making medical devices use it a lot. In aerospace, CAM programming helps make parts with tricky shapes and very strict measurements. In car making, it makes sure the engine parts are made very accurately, which makes the cars work better and use less fuel.

4. Parametric Programming:

“Complex but adaptable. Used in automotive manufacturing, mass production, and robotics for efficiency and adaptability.”

Parametric programming makes CNC machines more adaptable. It involves creating rules or conditions that guide the machine, allowing it to change its actions based on specific situations.

This method is helpful for complex tasks that require flexibility. While learning it may be a bit challenging, the ability to handle complicated jobs makes it worthwhile.

Parametric programming is suitable for industries like car manufacturing, mass production, and robotics. It’s beneficial for businesses that need to switch tasks quickly and efficiently.

For example, in car manufacturing, parametric programming can produce various car models on the same assembly line, adapting to different specifications effortlessly. In mass production, it enables machines to switch between different product types without manual adjustments, saving time and resources. In robotics, parametric programming helps robots adapt their movements to changing conditions, improving efficiency and safety.

A great read especially if you want to delve a little deeper into Parametric Programming: Quick Intro to Parametric Programming

Conclusion:

To sum up, CNC programming is really important for making things accurately and efficiently. The type you choose depends on how complicated the job is and how much you know. If you’re new, start with conversational programming. For more complicated and exact work, think about CAM or parametric programming. Knowing about these options helps people in manufacturing make things right.

To learn more about CNC Machines.

It’s a shame you don’t have a donate button! I’d certainly donate to this outstanding blog! I suppose for now i’ll settle for book-marking and adding your RSS feed to my Google account. I look forward to fresh updates and will share this blog with my Facebook group.