Cobots robots are designed to work safely right next to your team, making tasks quicker and safer. The secret to getting the most out of your cobots? It’s all about the tools they carry. End of arm tools (EOATs) can significantly change how your cobot works, from handling tiny components to moving heavy items. By choosing the right EOAT, you transform your cobot into the most valuable player on your production floor.

Let’s dive into how selecting the perfect tools can elevate your manufacturing game.

First, What are Cobots?

To simply put, cobots are robots designed to work hand-in-hand with humans. Unlike traditional robots that require separate spaces for safety reasons, cobots are built to share your workspace safely and efficiently. Cobots effortlessly taking on repetitive or heavy tasks to free up your time for more complex work. Their built-in safety features ensure they can operate right beside you without any hiccups. In essence, cobots are your on-the-floor helpers, boosting productivity and safety in your manufacturing processes.

So Then What are End of Arm Tools?

So, now that you know about cobots, let’s talk about end of arm tools (EOATs). Think of EOATs as the hands of your cobot. Just like you use different tools or gadgets for various tasks, cobots need EOATs to do their jobs. These tools can be grippers, suction cups, or even specialized tools for tasks like welding or painting. The right EOAT turns a cobot from just a robot into a versatile member of your team, capable of handling anything from delicate assembly to moving heavy objects. Essentially, EOATs are what make cobots adaptable to a wide range of tasks on your production line.

Why Do End of Arm Tools Matter?

Why do end of arm tools (EOATs) matter so much? It’s simple. EOATs are the key to unlocking the full potential of your cobots. Without the right tool, a cobot is just a machine standing idle. But with the perfect EOAT, it becomes an invaluable asset to your team. These tools allow your cobots to adapt to different tasks, whether it’s precision assembly, quality inspection, or heavy lifting. In short, EOATs are what enable your cobots to be as versatile and efficient as your manufacturing line needs them to be. They’re not just important; they’re essential.

Types of End of Arm Tooling:

Grippers:

Grippers are the most common EOATs you’ll find on cobots. They act like robotic fingers that can grab, hold, and move items around. Depending on what you’re working with, you can choose from several types: mechanical grippers are great for solid objects, while vacuum and pneumatic grippers handle delicate or irregular items smoothly. Each type has its own superpower, whether it’s gripping strength, precision, or adaptability to different shapes and sizes.

Suction Cups:

Suction cups are perfect for when you need a gentle touch. They work wonders on smooth, non-porous surfaces, making them ideal for handling glass, metal sheets, or any item where gripping might cause damage. Suction cups use vacuum technology to stick to objects, lifting them without leaving a mark. This is your go-to EOAT for tasks that require a soft grip and precision placement.

Tool Changers:

Tool changers allow your cobot to switch between different EOATs automatically, making it a jack-of-all-trades. Imagine your cobot handling assembly with a gripper, then swapping to a screwdriver to finish the job—all without manual intervention. Tool changers are the secret behind making your cobot versatile and multi-functional, ready to tackle a variety of tasks without skipping a beat.

Specialized Tools:

Sometimes, your cobot needs to do more specialized work. That’s where custom EOATs come in: welding torches, painting guns, and even inspection cameras. These tools are tailored for specific tasks, turning your cobot into a master craftsman. Whether it’s creating a perfect weld, applying a flawless coat of paint, or conducting detailed inspections, specialized tools ensure your cobot can handle tasks with expertise and precision.

By understanding the different types of EOATs available, you can outfit your cobot for virtually any task on your production line, maximizing efficiency and productivity.

Choosing the Right EOAT for Your Cobot:

Figure Out the Job:

First up, what do you need your cobot to do? Whether it’s lifting heavy items or putting together small parts, the job decides the tool. Identifying this helps you zero in on the right EOAT.

Look at What You’re Handling:

Consider the items your cobot will work with. Are they big, small, smooth, or oddly shaped? For flat items, a suction tool works great. For everything else, you might need a gripper that can adjust.

Match Tool to Cobot:

Ensure the EOAT fits your cobot. It’s like picking the right attachment for your vacuum cleaner; not every tool fits every model. Stick to the recommended list from your cobot’s maker to avoid any mix-ups.

Think About Your Workspace:

Your workspace matters. If it’s hot or wet, your EOAT needs to handle that without trouble. Pick a tool that can keep up with your environment.

Safety is Key:

Safety can’t take a back seat. Choose tools that keep your team safe. The right EOAT should work seamlessly with your cobot’s safety features, ensuring everyone can work together without worries.

Plan for Tomorrow:

Lastly, think about the future. Will this tool grow with you? Opting for an EOAT that’s flexible for different jobs means you’re set for longer, getting more bang for your buck.

By breaking it down step by step, you’ll find the perfect EOAT that not only tackles your tasks today but is also ready for whatever comes next. This way, your cobot becomes an indispensable part of your team, ready to take on challenges with you.

6 Types of Applications:

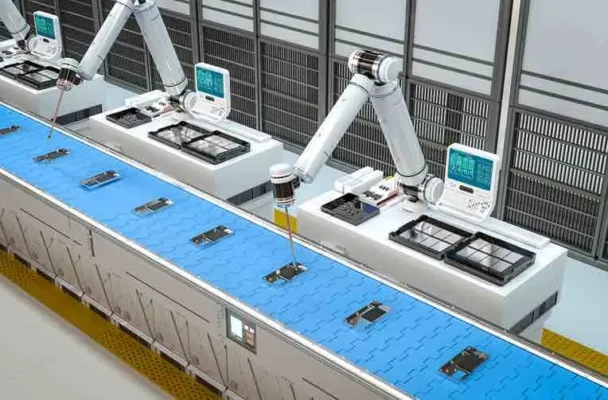

1. Pick & Place:

End-of-Arm Tools (EOAT) allow cobots to pick up and put down various parts at the same time. For example, magnetic EOAT can pick up and put down objects made of steel and iron but won’t affect non-ferrous objects.

2. Welding:

More and more companies are using welding tools for their spot-welding and arc welding tasks. It helps them make strong welds faster and keeps their workers safe. Cobots can do these jobs with little supervision, making the work quicker and safer.

3. Loading & Unloading Objects:

A company in Denmark that makes gears used a cobot and a collaborative gripper to move things in and out of its machines. They later switched to a double-grip gripper to make things even faster.

4. Material Removal:

One type of End-of-Arm-Tool (EOAT) is used to make holes and smooth materials. It’s often used in car factories.

5. Handling Delicate Objects:

Some EOATs use suction to pick up delicate items. You can adjust how strong they grip by changing the air pressure. They’re gentle and good for handling things like food.

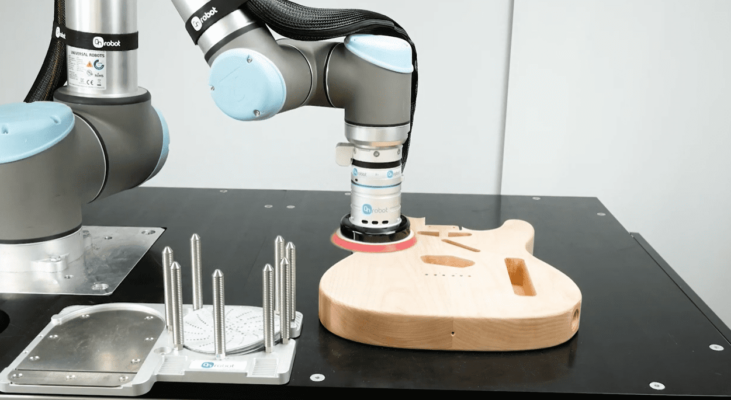

6. Polishing:

A glass company in France used a cobot with a sensor and gripper to improve glass polishing. This change made work easier, increased production, and made employees happier because they didn’t have to do the same repetitive tasks.

Conclusion:

Let’s sum it up: the real power of your cobots comes alive with the right end of arm tools (EOATs). These tools are not just accessories; they’re essential for making your cobots work hard and smart. From handling tiny components to moving big items, the right tool can drastically change what your cobots can do. Choosing the right EOAT is about matching the tool to the task, ensuring your cobots can take on any job you throw at them. It’s this choice that transforms your production line, making every task smoother and safer.

Do you want to compare different End of Arm Tooling?

Transform your cobot’s capabilities with the right tools! Join our community at Qviro Community to connect with experts and get insights on choosing the perfect end of arm tooling for your needs.