When exploring cobot costs, it’s important to look beyond the initial price tag and consider the overall value. Initial investments can vary widely. However, the real expense lies in integrating all the components to work seamlessly. Smart automation shoppers focus on the benefits and increased productivity rather than just the cost.

In this article, we will break down the different aspects of cobot costs, including startup, maintenance, and ongoing expenses, to help you understand the true value of investing in collaborative robots.

What is a Cobot?

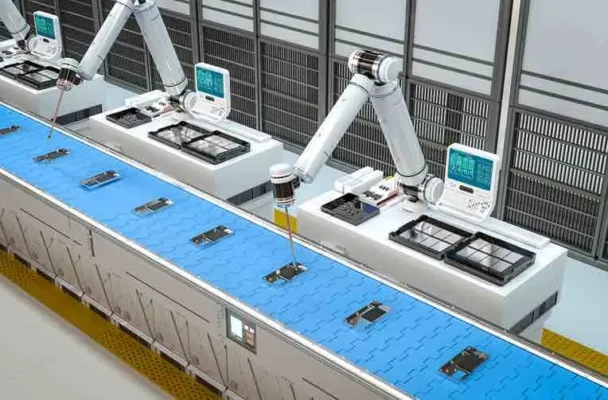

A cobot, or collaborative robot, is a type of robot designed to work alongside humans safely and efficiently. Unlike traditional robots that operate in isolated areas, cobots can share the same workspace with people, helping with tasks that are repetitive, dangerous, or require precision. They are equipped with advanced sensors and safety features to avoid accidents. Cobots are easy to program and can be quickly adapted to different tasks, making them ideal for various industries, including manufacturing, healthcare, and logistics. Their flexibility and user-friendly design help businesses improve productivity and reduce operational costs.

Cobot Costs:

When it comes to cobot automation, one of the first things people want to know is how much it costs. Let’s take a closer look at different cobot models and their starting prices:

The most expensive part of automation is making all the pieces work together, not just how much each piece costs.

When you’re a smart shopper for automation, it’s best to think more about what you get for your money than just the price tag.

You can figure this out by looking at how much more work you can do with automation and if it’s worth the money. Instead of only thinking about how much a robot costs, the people who make robots should talk about how much more work they can help you do.

Qviro.com lists over 300 cobots, offering businesses a variety of choices. This underscores how accessible and adaptable cobot automation is.

Breaking Down Automation Costs:

Here’s the important thing to know: When you use an automated machine to do a specific job, it’s only as good as the job it can do. For example, if you buy a machine for $200,000 and then realize you don’t need it a few months later, you can probably only sell it for $20,000 to $40,000, which is a lot less than what you paid.

In our article, Average Price of a Cobot [Study on 56 Cobots], we explore these costs in more detail.

Startup Costs for Automation:

When a business starts with automation, it needs to budget for several things:

- The cobot itself.

- Grippers for grabbing things.

- Frames for support.

- Sensors for feedback and safety.

- Safety devices to protect workers.

- Design and training time.

These costs can vary depending on your specific automation needs.

Maintenance Costs:

Once you have a cobot working for you, ongoing maintenance becomes crucial. Maintenance costs can include:

- Parts replacement to keep the cobot running well.

- Software support and updates.

- Labour hours for maintenance.

- Power usage.

- Preventive maintenance to ensure the cobot runs efficiently.

These costs are essential to keep your automation system running smoothly.

What You Get with Your Cobot:

When you buy a cobot, you usually get a package that includes:

- The robot arm.

- A power supply.

- A programming interface.

- A sturdy mounting stand.

- Cables for connecting to other equipment.

- External tools and sensors.

- Delivery, support, and maintenance services.

Checking what’s in your package helps you understand the total costs.

Ongoing Costs:

Besides the initial purchase, businesses need to budget for ongoing expenses like:

- Regular maintenance and servicing.

- Extra tools for specific tasks.

- Training for operators and maintenance staff.

- Software updates and support.

These expenses ensure your cobot continues to work efficiently.

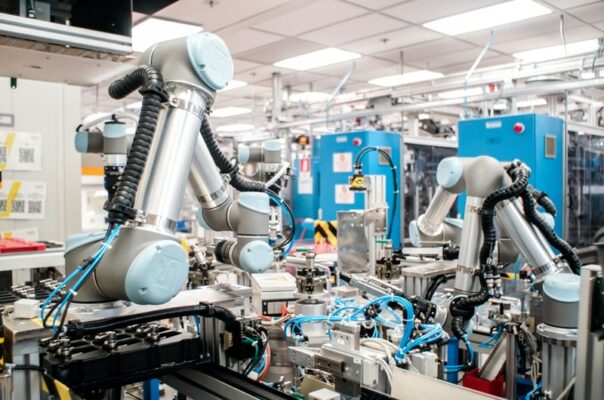

Industrial Robot Costs:

When it comes to industrial robots, the cost can vary significantly depending on factors like size, complexity, and brand. On average, industrial robots can range from approximately $35,000 to $120,000. These are rough estimates, and the actual prices can be higher or lower based on specific requirements and features.

What You Get with Your Industrial Robot:

When you buy an industrial robot, you usually receive the robot arm and its controller. However, you might need extra components for your specific tasks.

Additional Costs:

Additional costs for industrial robots may include:

- Safety measures to protect human workers.

- Tools and fixtures for specific tasks.

- Conveyor systems for moving materials.

- Cameras, sensors, and vision systems for quality control.

- Integration and programming to customise the robot for your needs.

Looking Beyond the Price Tag:

When thinking about automation, it’s essential to consider factors beyond the initial cost. These factors include:

- Integration costs, like programming and customization.

- Downtime during the transition to automation.

- Calculating the return on investment (ROI) to know when automation becomes profitable.

Conclusion:

In conclusion, cobot automation may seem costly at first, but it ultimately leads to enhanced productivity and savings in the long term. Therefore, it is crucial for businesses to evaluate their requirements for both immediate and future success. Collaborative robots bring transformation and a competitive edge as industries go increasingly automated. As industries evolve and embrace automation, investing in collaborative robots becomes a must for businesses aiming to thrive in our rapidly changing world.

Do You Need To Compare Different Cobots Models?

Join the Qviro community to discuss and understand the true cost and benefits of cobot automation with industry experts. Join the Qviro Community