Cobots, or collaborative robots, are reshaping how you approach automation. Unlike traditional industrial robots that require isolation, cobots are designed to safely work side-by-side with you and your team. They’re flexible, easy to program, and cost-effective, making them a practical choice even if you’re operating on a smaller scale. With a growing presence in industries from manufacturing to healthcare, cobots are tackling repetitive and complex tasks, freeing up your time for critical decision-making and problem-solving.

This guide dives into what cobots are, how they work, and why they might be the right automation solution for your business needs.

What is a Cobot?

A cobot, short for “collaborative robot,” is a type of robot designed to work alongside you and your team in a shared workspace. Unlike traditional robots that need to be isolated for safety, cobots are built with advanced sensors and safety features to detect your presence and avoid accidents. They’re easy to program, adaptable to various tasks, and can be set up quickly to handle anything from assembly and packaging to machine tending and quality inspection.

Because of their flexibility, cobots suit businesses of all sizes and are particularly valuable if you’re looking to automate without heavy upfront costs or complex setups. They take over repetitive or physically demanding tasks, freeing you to focus on higher-level work that requires human insight and decision-making. Cobots bring automation within reach for many industries, helping you improve productivity, maintain safety, and increase the efficiency of your operations.

How Does a Cobot Work?

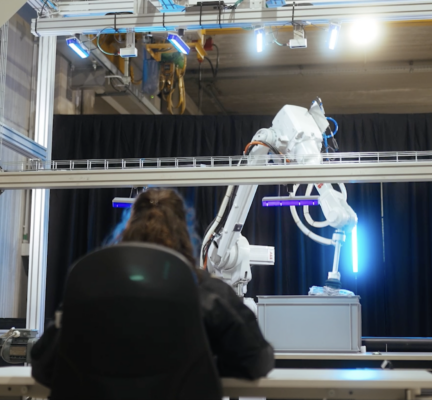

A cobot works by using sensors, cameras, and software to operate safely alongside you and your team. It’s designed to detect human presence and adjust its movements to avoid any collisions. For instance, if you or a coworker gets too close, the cobot can slow down, pause, or stop completely. This makes it safe for direct interaction.

Cobots are also designed for easy programming. You can set them up through simple software interfaces, which means no advanced coding is needed. Many cobots even allow you to “teach” them by guiding their arm through a task manually. This way, they learn specific movements and positions directly from you.

Cobots are often lightweight and can be moved between workstations to handle different tasks as needed. They’re flexible, so you can quickly reprogram them for various jobs, whether it’s assembly, packaging, or quality inspection, making them an adaptable tool in your operations.

How Do You Program a Cobot?

Choose Your Interface:

Most cobots come with an easy-to-use interface. You don’t need advanced programming skills—simply use a graphical interface to set up tasks. This visual layout makes programming intuitive and accessible for you and your team.

Drag-and-Drop Programming:

To start, select tasks from a menu and drag them into sequence. The software translates these steps into cobot actions automatically. This process speeds up setup and minimizes complexity, so you can get your cobot ready quickly.

Test & Optimize:

Before running tasks on the cobot, test them in a simulation. This helps you catch potential errors and fine-tune the sequence. Adjust tasks as needed in the interface to ensure the cobot performs as expected.

Maintain Flexibility:

Cobots are designed to be flexible. Reprogramming them is simple, so you can update tasks as your production needs change. This saves you time and reduces costs in the long run.

With these steps, you can program your cobot effectively, eliminating the need for specialized skills or extra technical support.

If you want to learn more about Cobot Programming:

How Much Does a Cobot Cost?

When you’re choosing a cobot, cost is an important factor. Based on Qviro’s research on 56 cobots, the average price is about €27,158. Generally, cobots with higher payload capacities cost more. So, if you need a cobot to handle heavier tasks, expect to pay a bit extra.

For a detailed look at cobot pricing, read our article, “Average Price of a Cobot [Study on 56 Cobots].” This guide breaks down the costs clearly, so you can make a decision that fits both your budget and production needs. With this information, you’ll be prepared to invest in a cobot that delivers value for your specific requirements.

Why Choose Cobots?

Safety for Your Team:

Cobots are designed to work safely right alongside you and your team. Unlike traditional robots, they don’t need to be isolated. With built-in sensors, cobots can detect people nearby and adjust their speed or stop to avoid accidents. This means you can add cobots to your workspace without making big changes to your layout.

Quick & Simple Setup:

Setting up a cobot is straightforward. You don’t need special programming skills—most cobots have easy drag-and-drop programming tools. This lets you get them up and running quickly. If you need to change tasks, you can reprogram your cobot with minimal downtime, keeping your operations flexible.

Affordable for Any Business:

Cobots are generally more budget-friendly than traditional robots. They’re a good choice if you’re looking to automate without overspending. With lower costs and simple maintenance, cobots provide a faster return on investment, making automation accessible to businesses of all sizes.

Increases Productivity & Reduces Repetition:

By taking on repetitive or physically demanding tasks, cobots free up your team for work that needs human focus and judgment. This not only boosts productivity but also makes your team’s work more engaging.

| Why Choose Cobots? | Details |

|---|---|

| Safety for Your Team | Cobots are designed to work safely with your team. Built-in sensors detect people nearby, adjusting speed or stopping to prevent accidents. You can integrate cobots without needing major workspace changes. |

| Quick & Simple Setup | Setting up a cobot is straightforward, with easy drag-and-drop programming tools. No special programming skills are needed. Reprogramming for new tasks is fast, minimizing downtime and maximizing flexibility. |

| Affordable for Any Business | Cobots are budget-friendly compared to traditional robots. They offer lower upfront and maintenance costs, providing a fast return on investment. This makes them ideal for businesses of all sizes. |

| Increases Productivity & Reduces Repetition | Cobots handle repetitive and physically demanding tasks, freeing your team to focus on work requiring human skills. This increases productivity and keeps work more engaging for your team. |

What are the Different Types of Cobots?

There are four main types of cobots, each designed for specific needs, as defined by the ISO 10218 standard:

ISO 10218 ensures safe human-robot interaction, reducing accident risks in workplaces with robots.

Power & Force Limiting Cobots:

These cobots prioritize safety. They have sensors to detect any contact with people and immediately adjust their force to prevent injury. They’re ideal if you need close human interaction during tasks.

Safety-Rated Monitored Stop Cobots:

These cobots stop automatically when someone enters their workspace. Built-in sensors detect people nearby and pause operations, making them suitable if your team frequently needs to work around the cobot.

Hand Guiding Cobots:

With hand-guiding cobots, you control the movements by hand. This makes them easy to adjust directly on the job, reducing downtime and increasing flexibility when you need to change tasks.

Speed & Separation Monitoring Cobots:

These cobots use sensors to maintain a safe distance from people. They slow down or stop when someone approaches, giving you a safe and reliable option in dynamic work environments.

There are about 300+ Cobots in the market, all listed on Qviro.com.

What is the Difference Between an Industrial Robot & a Cobot?

1. Adaptability:

Cobots are designed to easily adapt to changing environments. They can adjust to different tasks and work conditions without major modifications. In contrast, industrial robots require a consistent and stable setting to operate effectively. Any changes in their environment can disrupt their performance, necessitating time-consuming adjustments and recalibrations.

2. Flexibility:

Cobots are highly flexible and can quickly switch between tasks. They are designed to be versatile, handling a variety of jobs with minimal reprogramming. This makes them ideal for dynamic work environments. On the other hand, industrial robots need significant reprogramming to accommodate any new tasks or changes in the workflow, making them less adaptable to evolving production needs.

3. Cost-Effectiveness:

Cobots are generally more cost-effective than industrial robots. They are cheaper to purchase and integrate into existing workflows. Cobots require less setup time and fewer modifications to the workspace, which translates to lower overall costs. Industrial robots, while powerful, often involve higher initial investments and ongoing maintenance costs, making them a more expensive option for businesses.

4. Human Collaboration:

Cobots are built to work safely alongside humans. They come equipped with sensors and safety features that allow for close interaction without risk. This makes them suitable for environments where humans and robots need to work together closely. Industrial robots, however, usually operate in separate, enclosed areas to ensure safety. They lack the necessary safety features for direct human interaction, requiring additional safety measures like fences or cages.

| Features | Cobots | Industrial Robots |

|---|---|---|

| Adaptability | Cobots adapt easily to changing environments. They can adjust to new tasks and conditions with minimal modifications. | Industrial robots need a stable, consistent setting to work effectively. Changes in their environment may require time-consuming adjustments and recalibration. |

| Flexibility | Highly flexible, cobots can quickly switch between tasks with minimal reprogramming, making them ideal for dynamic work environments. | Industrial robots require significant reprogramming for new tasks or workflow changes, making them less adaptable to evolving needs. |

| Cost-Effectiveness | Generally more cost-effective, cobots are cheaper to purchase and easier to integrate with existing systems, resulting in lower setup and workspace modification costs. | Industrial robots usually have higher initial and maintenance costs, requiring more investment in setup and modifications, which can be expensive for businesses. |

| Human Collaboration | Cobots are designed to work safely alongside humans, with sensors and safety features allowing close interaction without risk. | Industrial robots operate separately, typically in enclosed areas. They lack built-in safety features for direct human interaction and require additional safety measures like fences or cages. |

What are the Applications of Cobots?

1. Assembly:

Assembly cobots are excellent at assembling parts in industries like electronics and automotive. They improve product quality and reduce errors. Easy to program and flexible, cobots handle repetitive tasks efficiently, ensuring precision and consistency. By working alongside human workers, cobots boost productivity and maintain high standards in the assembly process.

2. Quality Inspection:

Quality inspection cobots use cameras to check your products for defects. They ensure you only sell top-quality items. These robots spot flaws accurately, improving your inspection process. By consistently checking each product, cobots help you maintain high standards, reduce waste, and keep your customers happy. They are essential in industries where quality matters most.

3. Material Handling:

Material handling cobots efficiently move items around your workspace. They help with sorting and packing, reducing the workload on you and your team. By handling these tasks, cobots increase productivity and ensure smooth operations. This makes them valuable in any industry where moving materials is essential.

4. Machine Tending:

Cobots manage machines efficiently. They handle tasks like loading and unloading materials, freeing you to focus on more complex work. By taking over repetitive tasks, cobots increase productivity and ensure consistency. They are easy to program and can adapt to different machines, making them valuable in various industries.

5. Packaging:

In packaging, cobots place and prepare goods for shipping accurately. They help prevent damage during delivery by handling items carefully and consistently. By taking over these tasks, cobots reduce errors and increase efficiency. This ensures your products reach customers in perfect condition, enhancing satisfaction and trust in your brand.

6. Welding:

Welding cobots make welding safer and more precise. They handle repetitive welding tasks, ensuring consistent quality and reducing human error. With built-in safety features, cobots protect workers from hazardous welding fumes and sparks. They are easy to program for different welding jobs, making them adaptable to various projects. By taking on the heavy lifting, cobots free you to focus on more complex tasks, improving overall productivity and safety in your workspace.

Top 5 Benefits of Using a Cobot:

1. Safety:

Cobots are designed with safety in mind, reducing the risk of injuries. They come equipped with advanced sensors and safety features that ensure they can operate safely around humans. This is especially important during hazardous tasks where human workers might be at risk. By using cobots, you can create a safer work environment and minimize the chances of workplace accidents.

2. Flexibility:

Cobots can easily switch between tasks, making your workflow smoother and more efficient. They are designed to be versatile and can adapt to different tasks with minimal reprogramming. This flexibility means less downtime and more productive use of your resources. Cobots can quickly adjust to new processes or changes in production, ensuring continuous and efficient operations.

3. Precision:

Cobots perform tasks with high precision, which improves the quality of your products. They can execute repetitive tasks with consistent accuracy, reducing the margin of error. This level of precision ensures that each product meets the required standards, leading to better quality control and higher customer satisfaction.

4. Increased Productivity:

Cobots can work non-stop, significantly increasing productivity. Unlike human workers, cobots do not need breaks, rest, or shift changes. This continuous operation means that cobots can produce more and complete tasks faster. By integrating cobots into your workflow, you can enhance your production capacity and meet tight deadlines more effectively.

5. Savings:

Cobots help reduce costs and improve your bottom line. They are generally more affordable to purchase and maintain than traditional industrial robots. Cobots also lower labor costs by automating repetitive and time-consuming tasks. Additionally, by increasing efficiency and reducing errors, cobots help businesses stay competitive in the market. Overall, cobots offer a cost-effective solution to enhance your operations and drive business growth.

| Benefits of Using a Cobot | Details |

|---|---|

| Safety | Cobots are designed with safety as a priority. Equipped with advanced sensors, they can operate safely around humans, reducing the risk of injuries, especially during hazardous tasks. By using cobots, you create a safer work environment and minimize workplace accidents. |

| Flexibility | Cobots can switch between tasks easily, streamlining your workflow. Their versatility allows them to adapt quickly to new processes with minimal reprogramming, reducing downtime and making efficient use of resources. |

| Precision | Cobots perform tasks with high accuracy, enhancing product quality. They handle repetitive tasks consistently, reducing errors and ensuring each product meets required standards, improving quality control and customer satisfaction. |

| Increased Productivity | Cobots work continuously without breaks, increasing productivity. Unlike human workers, they don’t require rest, enabling faster task completion. Integrating cobots boosts your production capacity and helps meet tight deadlines effectively. |

| Savings | Cobots reduce costs and improve your bottom line. They are affordable to purchase and maintain compared to traditional robots, lower labor costs, and increase efficiency, offering a cost-effective solution that drives business growth. |

Need Free Robot Project Advice?

5 Limitations of Using a Cobot:

1. Limited Payloads:

Cobots are built for lighter tasks. If you need heavy lifting, traditional industrial robots are more effective. Cobots aren’t designed for high-weight demands.

2. Need for Human Supervision:

Cobots still need human supervision, especially in settings where tasks can change or be unpredictable. You’ll need to monitor them to keep everything running smoothly and safely.

3. Lower Speed:

Cobots work slower than traditional robots. Their focus on safety and accuracy means they may not keep up with high-speed production needs.

4. Strict Safety Standards:

Cobots must meet strict safety requirements. This ensures safety but can limit what tasks they can handle. Make sure your application fits within these guidelines.

5. Complex Integration:

Integrating a cobot with your existing systems can be challenging. Setup and customization may take extra time and resources. You might need additional expertise to get everything working as needed.

| Limitations of Using a Cobot | Details |

|---|---|

| Limited Payloads | Cobots are built for lighter tasks. If you need heavy lifting, traditional industrial robots are more effective. Cobots aren’t designed for high-weight demands. |

| Need for Human Supervision | Cobots still need human supervision, especially in settings where tasks can change or be unpredictable. You’ll need to monitor them to keep everything running smoothly and safely. |

| Lower Speed | Cobots work slower than traditional robots. Their focus on safety and accuracy means they may not keep up with high-speed production needs. |

| Strict Safety Standards | Cobots must meet strict safety requirements. This ensures safety but can limit what tasks they can handle. Make sure your application fits within these guidelines. |

| Complex Integration | Integrating a cobot with your existing systems can be challenging. Setup and customization may take extra time and resources. You might need additional expertise to get everything working as needed. |

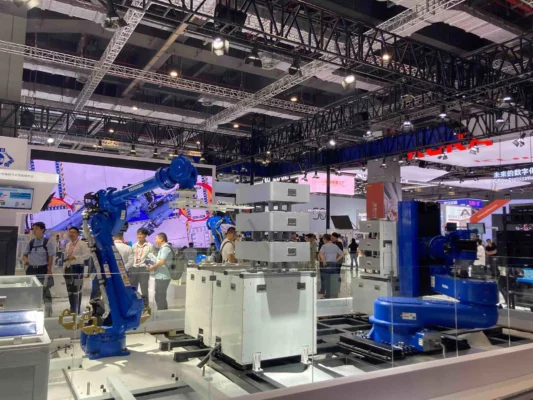

5 Popular Cobot Brands:

Many top companies have made big progress in the world of collaborative robotics, changing the way industrial automation works. Let’s take a look at some outstanding cobot brands:

1. Universal Robots:

As the most reviewed and market leader, UR is renowned for its flexible and user-friendly cobots. Their range includes models like UR3e, UR5e, UR10e, UR16e, and UR20, suitable for a wide array of applications.

2. ABB:

With extensive robot experience and outstanding support, ABB Robotics is a trusted choice. Their expertise adds depth to your automation endeavors.

3. Doosan Robotics:

Doosan has a lot of different robots that can do many jobs. They are flexible and work well, which is good for many industries.

4. Kinova Robotics:

Kinova Robotics makes robots that are lightweight and can do lots of different tasks without costing too much. Their robots are fast and can change jobs easily.

5. FANUC:

FANUC is a big name in making machines for businesses. Their cobots are good because they are very exact and reliable. They work well for industries like making cars, electronics, and planes.

Want to find a suitable cobot for your application? Check out the best cobots of 2025:

Implementation Challenges & Tips:

Challenge 1: Integrating with Your Current Systems

Cobots need to work smoothly with your existing equipment, which may require adjustments.

Tip: Start by checking if your cobot is compatible with your current setup. Make sure it can connect easily to your machinery and processes to avoid issues during setup.

Challenge 2: Training Your Team

Your team will need training to use the cobot effectively, even though it’s designed to be user-friendly.

Tip: Focus on essential skills like basic programming and safety procedures. Clear, hands-on training helps your team feel confident and ready to work with the cobot.

Challenge 3: Ensuring Consistent Performance

Cobots can struggle with tasks that change often or have many variables.

Tip: Regularly monitor your cobot’s performance and adjust its programming if needed. Keep tasks clear and check in often to ensure it’s delivering reliable results.

By tackling these challenges head-on and following these tips, you can set up your cobot smoothly and improve both safety and efficiency in your operations.

To learn more about Challenges When Implemnting Cobots:

Conclusion:

Cobots are changing how you work, making automation more accessible and safe. They’re designed to work alongside you and your team, taking on repetitive tasks that free up your time for more complex work. Cobots are flexible, easy to program, and affordable, fitting seamlessly into companies of all sizes. As technology advances, cobots are expected to become even smarter and safer, giving you more options to streamline your operations. Whether you want to boost productivity, enhance safety, or reduce costs, cobots offer a practical solution to help you stay competitive and efficient in today’s fast-paced environment.

Are You Looking to Compare Different Cobots?