Choosing the right robot for your business can greatly impact your efficiency and safety. In this blog, you’ll learn about two main types: Cobots (collaborative robots) and traditional industrial robots. Both have specific strengths, but it’s important to understand how they differ so you can make the best decision for your needs.

We’ll break down the key points, like safety features, ease of use, cost, and how they fit into your work environment. Whether you’re focused on improving teamwork or handling heavy-duty tasks, this guide will help you decide which robot suits your business best.

What is a Cobot?

A Cobot, is a robot designed to work with people. Unlike industrial robots, Cobots are made to be safe around humans. They have sensors that help them know when a person is nearby, so they can slow down or stop to avoid accidents.

Cobots are easier to program and can be used for many different tasks. They are not as powerful or fast as industrial robots, which makes them safer to work with. People can teach Cobots what to do without being experts in robotics. These robots are great for jobs where people and robots need to work together, like assembling things or checking for quality.

What is an Industrial Robot?

An industrial robot is a specialized machine used in factories. It does tasks that need to be precise and repeatable, like welding or moving heavy things. These robots can come in different sizes and shapes. Some are big and used in car factories, while others are smaller and used in making electronics.

These robots are good at doing the same task over and over again. They are very accurate and can work fast. But they usually work separately from people because they can be dangerous. There are safety measures like fences or sensors to keep people safe when they are around industrial robots.

What are the Differences?

Cobots team up with people to make automation safer and better. They have some key differences from traditional robots:

1. Safety:

Cobots are built to safely work near people. They have sensors and smooth edges to minimize risk. Traditional robots, on the other hand, rely on physical barriers for safety and prioritize efficiency over safety features.

2. Flexibility:

You can use cobots for a wide range of tasks because they’re lightweight and versatile. They fit into different environments easily. Industrial robots are usually built for specific jobs and are harder to move or adapt.

3. Programming:

Cobots are user-friendly. You and your team can easily program and operate them without much training. Traditional robots need complex programming and specialized knowledge, which can take more time and resources to manage.

4. Costs:

Cobots are cheaper to set up and bring quicker returns on investment (ROI). They have lower startup costs. While traditional robots may cost more initially, they can offer higher ROI in large-scale, repetitive tasks over time.

To learn more about calculating ROIs, check out this article:

5. Payload & Speed:

Cobots are slower and handle lighter tasks to maintain safety. Traditional robots are faster, stronger, and built for handling heavier, more demanding jobs like large-scale manufacturing.

6. Working with People:

Cobots require human interaction for tasks such as programming and maintenance. Industrial robots can operate independently once programmed, needing less human involvement day-to-day.

7. Different Environments:

Cobots can adjust to various workspaces, making them suitable for different industries. Traditional robots need controlled environments with additional safety measures to ensure proper functioning.

8. Expertise :

Cobots are adaptable and can easily switch between tasks. Industrial robots are highly specialized and typically focus on doing one specific task very well.

9. Lifespan:

Industrial robots are built to withstand tough environments and last for a long time. Cobots are more focused on flexibility and adaptability, which may reduce their durability in harsh conditions.

10. Safety Rules:

When working with cobots, strict safety guidelines are in place since they interact directly with people. Traditional robots have fewer safety rules, especially in areas where no people are present.

Here’s a quick breakdown of how cobots differ from traditional industrial robots to help you understand which one fits your needs better:

| Features | Cobots | Industrial Robots |

|---|---|---|

| Safety | Designed to work near you. They use sensors and soft edges to reduce risk. | Require barriers to separate them from people. They focus more on efficiency than safety. |

| Flexibility | Lightweight and adaptable. You can easily move them and use them for different tasks. | Built for specific jobs. They are harder to move and less flexible. |

| Programming | You can easily program cobots without much training. They are user-friendly. | Eequire complex programming and expert knowledge. They take more time to set up. |

| Costs | Cheaper to set up and give you faster returns on investment. | Cost more upfront, but may offer better returns for large-scale tasks over time. |

| Payload & Speed | Work slower and handle lighter tasks to keep you safe. | Faster and stronger. They handle heavy-duty tasks. |

| Working with People | Require your help for programming and maintenance. | Work independently after setup, needing less attention from you. |

| Different Environments | Fit into different environments and industries. | Require controlled environments and safety measures to work properly. |

| Expertise | Versatile and can quickly switch between tasks. | Highly specialized for one task and do it with high precision. |

| Lifespan | Flexible, but may not last as long in tough conditions. | Built to last in harsh environments, making them more durable. |

| Safety Rules | Must follow strict safety rules when working with you. | Have fewer safety rules when they work in areas without people. |

Deciding Between Cobots & Industrial Robots?

When you have to choose between Cobots and traditional industrial robots, think about these important things:

1. Industry Requirements:

If you work in electronics, cobots are good for delicate assembly. In the automotive industry, industrial robots handle heavy tasks like welding more efficiently.

2. Task Type:

If your tasks change often, like packaging different products, cobots can adjust quickly. If your production is repetitive, like assembling identical items, industrial robots are better for the job.

3. Work Environment:

If you have a smaller workspace with people working nearby, cobots are safer. Industrial robots work best in larger spaces where they don’t need to interact with people.

4. Team Skills:

If your team doesn’t have programming experience, cobots are easier to use. If your team has technical skills, industrial robots offer more advanced options.

5. Automation Goals:

If your goal is to improve safety and reduce physical strain on workers, cobots are the way to go. If you need high-speed production, industrial robots will deliver better results.

Stäubli’s TX2-Series in Action

What’s the Cost Difference Between Cobots & Industrial Robots?

When you’re deciding between cobots and industrial robots, the cost is a key factor.

Cobots Cost:

Cobots are more affordable upfront. You can expect to pay between $30,000 and $50,000 depending on the model. They also cost less to install and train your team to use, meaning you get a faster return on your investment. Cobots are a good option if you want flexible automation without breaking your budget.

To learn more about Cobot Costs, check out this article:

Industrial Robots Cost:

Industrial robots are more expensive, usually costing between $50,000 and $150,000. On top of that, you’ll need to budget for setup, programming, and extra safety measures. These robots are a better fit if you’re working on large-scale production where speed and efficiency are critical.

To learn more about Industrial Robot Costs, check out this article:

Switching to Collaborative Automation:

Cobots are becoming more common because they are flexible, easy to use, and improve your workplace. They won’t replace your job but will work with you to make tasks easier.

Why Use Cobots?

Cobots are perfect for repetitive, tiring, or risky tasks. This helps you avoid physical strain and keeps your team safer, allowing you to focus on more important work.

Where Cobots Help:

You can use cobots for jobs like picking items, working on assembly lines, tending machines, packing, moving goods, and restocking. They fit into many different industries and help boost your efficiency without taking away your control over key decisions.

By switching to collaborative automation, you’ll make your operations smoother and more productive, without losing the human touch that makes your business unique.

Balancing Cobots & Traditional Robots:

Cobots are great for flexibility and safety, but industrial robots still have a big role in your automation setup. Each has specific strengths, and using both can make your operations smoother.

When You Need Industrial Robots:

Use industrial robots for jobs that need speed, precision, and strength. They’re perfect for tasks like welding, painting, moving heavy materials, and assembling products on a large scale. These robots are ideal when you need reliable, fast results in tough environments.

When You Need Cobots:

Cobots are your go-to for tasks where you need flexibility and teamwork. They handle repetitive or lighter tasks and can quickly adjust when your workflow changes. Cobots are best when safety and adaptability are top concerns.

By using both cobots and industrial robots, you can ensure your workplace is efficient, safe, and tailored to the needs of different tasks.

Future of Automation:

The automation world is changing fast, and Cobots are becoming more important.

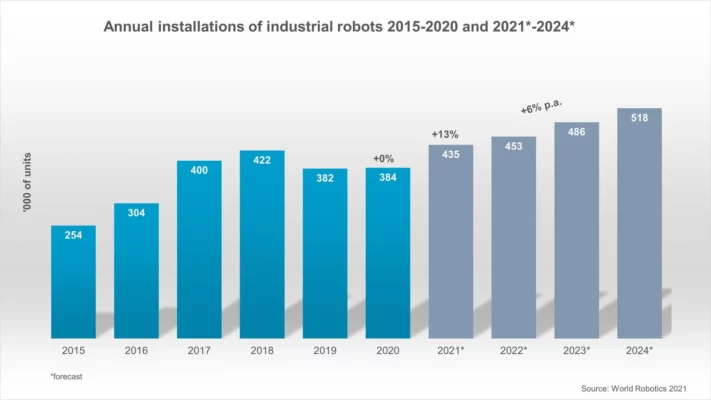

In 2020, the International Federation of Robotics (IFR) said that the number of industrial robots sold worldwide reached 420,000, which was 4% more than the year before. This growth is because more and more industries are using Cobots.

The chart shows the steady rise in annual installations of industrial robots from 2015 to 2024, with forecasts indicating continued growth beyond 2021. (IFR, 2024)

Likewise, a report from MarketsandMarkets predicts that the market for collaborative robots will keep growing at a steady rate, by 41.8% from 2021 to 2026, reaching a value of $8.4 billion. This means that more people are using Cobots in manufacturing and other fields.

Conclusion:

In your journey through automation, it’s important to understand how Cobots and traditional robots can enhance your operations. Cobots are tailored to collaborate with you, simplifying programming and boosting safety for team-oriented tasks. Traditional robots excel in precision and efficiency, ideal for repetitive or hazardous tasks that require minimal human interaction. By knowing when to use each type of robot, you can boost your productivity and ensure a safer, more innovative workplace. This knowledge is key to making informed, effective decisions in automation.

Are you looking for a System Integrator?