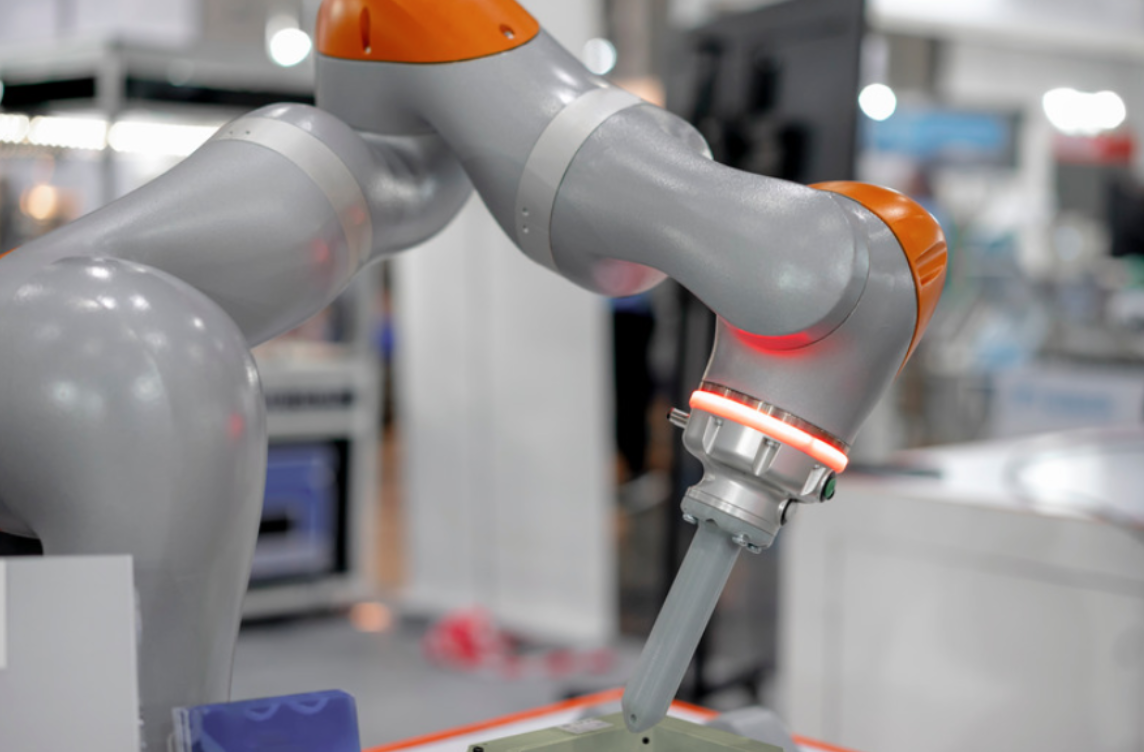

Grippers are like robot hands, and they connect to the robot’s wrist. They help the robot do tasks like picking up and holding things. The gripper is at the end of the robot’s arm, and it works like a human hand, making the robot good at many different jobs. It can handle delicate things or heavy stuff, which makes the robot work better.

Types of Grippers:

1. Hydraulic Grippers: Strong, But Watch for Oil Spills

Hydraulic grippers are powerful tools for heavy tasks due to their high-pressure pumps. They can lift items weighing 50 kilograms or more. However, there are important considerations:

Firstly, hydraulic grippers can be messy as they use oil in the pumps, which might spill. Additionally, because they exert a lot of force, they are more prone to damage. Therefore, regular maintenance is essential to keep them in good shape.

2. Electric Grippers: Precise & Easy to Use

Electric grippers, also called servo-electric grippers, use an electric motor for their fingers. They work with electricity, which makes them easy to use. While they may not be as strong as hydraulic grippers, they have their advantages, especially in tasks like machine tending and pick & place.

Electric grippers are recognized for their precision and ease of use, making them a preferred choice in many cobot setups.

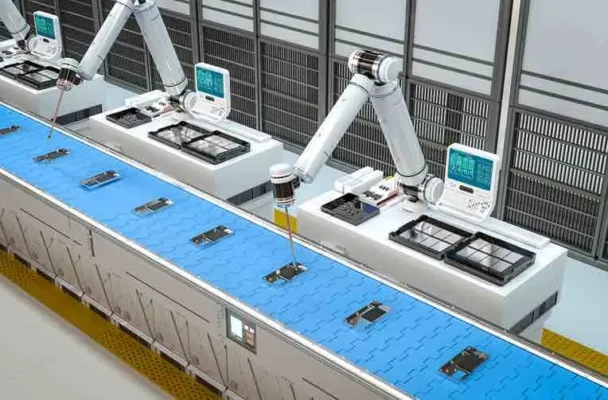

3. Pneumatic Grippers: Efficient Pick-and-Place

Pneumatic grippers use compressed air to control their fingers. These fingers work like human fingers, securely holding and releasing items. They are excellent for precise and reliable tasks, like pick-and-place jobs in manufacturing and automation.

4. Adhesive Grippers: Flexible & Cost-Effective

Adhesive grippers are flexible and cost-effective. They grip things well without needing power. They’re lightweight and can handle many objects. This makes them good for different uses. Adhesive grippers are practical when power is limited. They are versatile, convenient, and cost-effective for robot gripping.

Other gripper types include magnetized grippers, dual grippers, and sensory feedback grippers.

Gripper Components:

To pick the right gripper, think about these things:

1. Size:

Check if the gripper can reach and handle parts properly. Don’t use too long fingers to avoid straining the gripper and robot.

2. Weight:

The gripper should handle the part’s weight, including any sudden movements. Don’t use maximum force to avoid breaking things.

3. Surface:

Understand what the gripper will touch. Different surfaces might need more or less force or specific gripper materials for a good grip.

By looking at these factors, you can choose a gripper that matches your application’s size, weight, and surface needs. This way, you’ll have a strong and reliable grip without damaging the gripper or the things it holds.

Choosing the Right Gripper:

When picking a gripper, focus on your job. Here are important things to think about:

1. What You Handle:

Decide if it’s one kind of thing or many. This affects how well it can adapt.

2. Specific Job:

Think about what you’ll touch. Food, electronics, or dangerous stuff? Grippers are made for different needs.

3. How Much It Holds:

Figure out how heavy the gripper needs to lift. Make sure it can pick stuff up right.

4. Space:

Check if it fits in small places. Some are for tight spots.

5. Feedback:

Decide if you need info from the gripper. Some grippers have sensors for grip strength, position, or finding objects. This is important for quality control.

Cycle Time: How Fast It Grabs and Lets Go

Think about how fast the gripper grabs and releases things. This is called the cycle time. The speed of these actions affects how quickly tasks get done. Depending on your job, you might need a faster cycle time for better productivity.

Different grippers come with different speeds for clamping and opening/closing. Look at the gripper’s details to make sure it matches the time you need for your job. Choosing a gripper that works at the right speed can make work smoother and faster.

Advice:

1. Gripper Weight and Robot Specs: If the gripper is heavy, it can slow down the robot. So, pick a lightweight gripper for better performance.

2. Precision and Adaptability: If you need high precision, use a mechanical gripper with servo-electric motors. It’s great for assembling things accurately.

On the other hand, if you’re sorting stuff or need to handle things of different sizes, get a gripper that can adapt and move things around as needed. It helps you sort and organize items the way you want.

So, choose a gripper that matches your task. It’ll make your robot work better and get the job done the way you want it to.

Work Environments:

When choosing cobot grippers, think about where you’ll use them:

1. Food & Pharmaceutical Industries:

Avoid hydraulic grippers because they can cause oil spills and contamination. Instead, follow industry rules by using electric or pneumatic grippers.

2. Clean Room Industries:

Avoid vacuum and pneumatic grippers as they can stir up air particles. Choose grippers that emit low air or particles to keep things clean.

3. Dirty Environments:

If your gripper will be exposed to dirt and particles, make sure it’s protected. This will keep it working well and prevent damage or clogs from outside debris.

4. Corrosive or Toxic Environments:

In places with corrosive or toxic substances, like nuclear or chemical industries, you need special grippers with the right coatings or materials. This ensures stability and safety.

Matching your gripper to your work environment ensures it works well, lasts, and stays safe in your cobot tasks.

Maintenance and Durability:

Understand Your Gripper’s Needs

Each type of gripper has its own care instructions. Knowing these will help you keep your gripper working well for a long time.

Hydraulic Grippers: Check for Leaks

Hydraulic grippers are strong but can leak oil. Make sure to check the oil levels and look for leaks regularly. This keeps the gripper from breaking down.

Electric Grippers: Update and Check

Electric grippers need their software updated and their electrical parts checked. This keeps them precise and reliable.

Pneumatic Grippers: Watch the Air

With pneumatic grippers, it’s all about the air. Make sure there are no leaks and the air filters are clean. This prevents blockages and keeps the gripper moving smoothly.

Adhesive Grippers: Keep Clean

Adhesive grippers need their surfaces cleaned often. This helps them hold onto things better.

Routine Checks: A Must

No matter your gripper type, regular checks are key. Follow the maker’s advice on care to avoid surprises. This way, your gripper stays ready for work.

Why It Matters

Good maintenance means your gripper works well and lasts longer. It prevents stoppages that can slow down your work. Taking care of your gripper saves time and money in the long run.

Cost Considerations:

Initial Investment: Know the Price Tag

The first thing to look at is how much a gripper costs upfront. Prices vary widely based on the type:

- Hydraulic Grippers: These can be pricey, with costs ranging from $500 to over $2,000. They’re powerful but might stretch your budget.

- Electric Grippers: Expect to pay between $250 and $1,500. They’re a bit more affordable and offer great precision.

- Pneumatic Grippers: These are usually the most budget-friendly, ranging from $100 to $800. They’re simple and effective for many tasks.

- Adhesive Grippers: Often the least expensive, with prices as low as $50 to $300. They’re cost-effective and versatile for light tasks.

Operational Costs: Think Long-Term

Don’t forget to consider how much it costs to run your gripper.

- Hydraulic and Pneumatic Grippers may have higher ongoing costs because they need air or oil, which adds up over time.

- Electric Grippers tend to have lower operational costs since they just use electricity.

- Adhesive Grippers have minimal running costs, making them a good choice for saving money in the long run.

Making the Smart Choice

Your budget isn’t just about buying the gripper; it’s also about keeping it running. Think about both the initial price and what you’ll spend over time. Sometimes spending a bit more upfront can save you money down the road. Choose the gripper that fits both your needs and your budget to get the best value.

Conclusion:

Choosing the right gripper is a big decision. You need to think about what you’re handling, how much it weighs, and where you’re working. Don’t forget to consider how much the gripper costs, both upfront and over time. Each type of gripper—hydraulic, electric, pneumatic, and adhesive—has its own benefits and costs. By understanding your needs and how each gripper fits into them, you can make a smart choice. Pick a gripper that does the job well without breaking your budget. The right gripper will make your work smoother and more efficient.

Do you want to compare different Grippers?

Want to dive deeper into the world of robot grippers and find the best fit for your needs? Join our community at Qviro Community to connect with experts and explore comprehensive insights and comparisons!

Are you looking for a System Integrator?