Diving into industrial automation? Let’s talk about End of Arm Tooling (EOAT) – your robot’s hand. It’s what grabs, holds, or manipulates your products. If you’re aiming to boost your manufacturing line or just exploring automation options, getting to know EOAT is essential.

This guide is designed for you. It breaks down the types of end effectors and gives you tips for picking the right tooling. Focused on your specific needs, we’re here to help you choose smartly, enhancing efficiency and productivity on your floor.

What is an End of Arm Tool?

An End of Arm Tool (EOAT) is like the hand for your robot. It’s the part that touches, holds, or moves your products. Each EOAT is made for a specific job, making your robot flexible and ready for any task.

Why is this important for you? The right EOAT boosts your line’s speed and precision. Whether you’re moving fragile items or heavy parts, there’s an EOAT built for that job.

You’ll find EOATs in many shapes: grippers that grab things, suction cups that stick to items using vacuum, and tools made for welding, cutting, or painting. The best part? You can switch EOATs to make your robot do different jobs, making your automation system super versatile.

Knowing about EOATs is key to automation. They’re not just tools; they’re your way to more productivity, better quality, and faster operations. Choose the right EOAT, and watch your robot work smarter and faster.

3 Basic Types of End of Arm Tooling:

Let’s break down the three main types of end effectors you’ll encounter, making it easier for you to pick the right one for your job.

Mechanical Grippers:

These grippers grip and hold items tightly, perfect for a variety of tasks. Whether you’re moving metal parts or plastic pieces, mechanical grippers are up for the challenge. They’re like the all-rounders on your team, ready to tackle most jobs you throw their way.

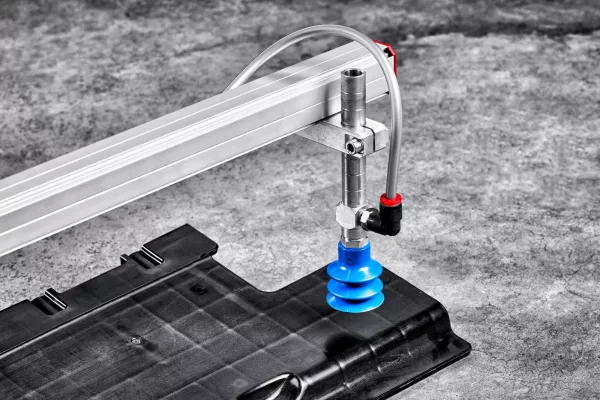

Vacuum Grippers:

Imagine a robot with suction cups. That’s your vacuum gripper. They’re best for picking up smooth, flat, or awkwardly shaped items that other grippers can’t handle well. Vacuum grippers stick to objects using air pressure. They’re gentle, making them ideal for moving delicate or light stuff. Quick and smooth, they keep things moving fast on your line.

Magnetic Grippers:

This gripper is a magnet strong enough to lift and move metal objects. Magnetic grippers are your go-to for handling anything made of ferrous metal. Heavy, bulky metal parts? No problem. Magnetic grippers grab them with ease, offering precise control and strength.

Choosing the right end effector is crucial. It’s about matching the tool to your specific needs. Whether you’re dealing with electronics, packages, or metal, the right end effector boosts your robot’s efficiency. Pick wisely, and watch your productivity soar.

3 Examples of End-of-Arm Accessories:

Let’s explore some key accessories that can supercharge your robot’s end effector, making your automation setup even more efficient.

Sensors:

Imagine giving your robot the ability to feel. Sensors do just that. They help your robot detect the presence of objects, measure force, or even identify the exact position of items. This means your robot can adjust its grip or know when it’s successfully picked something up, reducing errors and improving quality.

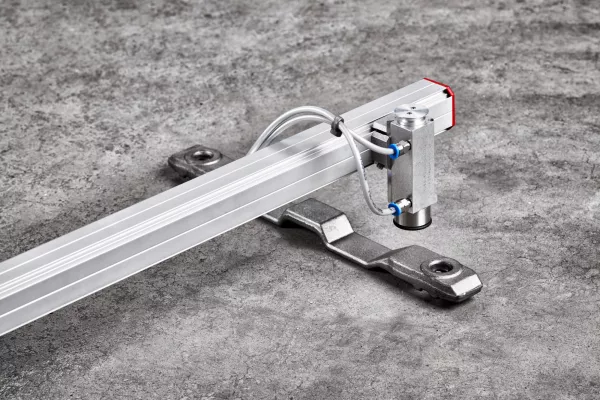

Tool Changers:

Tool changers are like quick-change outfits for your robot. They allow your robot to switch between different tools or grippers without manual help. This is perfect when your robot needs to perform multiple tasks, like picking up an item with a gripper and then switching to a drill. It’s all about versatility and speed, keeping your production line moving without delays.

Compliance Devices:

Think of compliance devices as shock absorbers for your robot. They let the end effector adjust its position slightly to fit perfectly with the part it’s working on. This is especially useful for precise tasks, like fitting a part into a tight space. Compliance devices help avoid damage to both the robot and the items it handles, ensuring smoother operations.

Adding these accessories to your robot’s end effector can significantly enhance its capabilities. Whether it’s sensing, switching tools on the fly, or making precise adjustments, these add-ons help you get more out of your automation investment.

4 Main Types of Tooling:

Let’s explore the tooling types for your robot and clarify how they’re different from the extra gadgets you can add on.

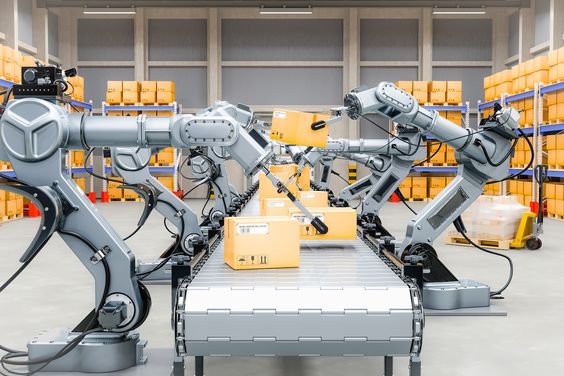

Gripping Tools:

These are your robot’s fingers. They help grab and move things. You’ll find ones that can gently hold delicate items or ones strong enough for heavy metal parts.

Cutting Tools:

Need to cut materials? Robots can have tools for precise cutting, like lasers or waterjets, and even simpler tools for sawing or shearing.

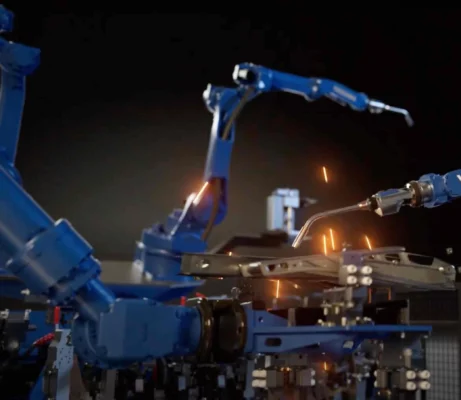

Welding Tools:

For joining metal parts, robots can be equipped with welding tools. They do the job quickly and precisely, whether it’s a small spot or a long seam.

Dispensing Tools:

Perfect for tasks that need a steady hand, like applying glue or paint. These tools make sure everything’s applied just right, every time.

Tooling vs. Accessories:

So, what’s the difference between these tooling types and the extra accessories?

The tooling types (like grippers or welders) decide what your robot does—its main job. The accessories, on the other hand, are like bonus features. They include sensors for extra precision, tool changers for quick swaps, and devices that let your robot adjust its grip or position. These extras don’t change what the tool does but make it work better. Understanding this helps you tailor your robot for the perfect balance of skill and flexibility, boosting your project’s success.

5 Tips To Help You Choose The Right End-of-Arm Tooling:

Picking the right End-of-Arm Tooling (EOAT) for your robot can really boost your project’s success. Let’s dive into the main points to consider, making sure you get the best fit.

Your Task:

Start by thinking about what job your robot will do. Will it be picking up items, putting things together, or painting? The task decides the type of EOAT you need. Each job needs a different tool, so identify your task first.

Look at Your Parts:

What will your robot handle? The size, shape, weight, and material of these items are key. For example, a tool good for metal might not suit soft materials. Knowing about your parts helps pick an EOAT that handles them right.

Robot Match-Up:

Make sure the EOAT fits your robot. It’s not just about physical size but also about how they communicate. They need to work well together for smooth operation.

Work Environment:

Where will your robot work? Hot, cold, dusty, or wet conditions can affect EOAT choice. Some tools are tough and can handle extreme conditions; others might need extra care. Pick one that’s reliable where you’ll use it.

Safety is Key:

Finally, think about safety. The EOAT should be safe for both the robot and people around it. Choose tools with safety features that meet your industry’s standards.

By focusing on these points, you’ll be able to choose the right EOAT, making your automation project more effective and safe.

Key Considerations Before Purchasing Any EOAT:

When picking the perfect End-of-Arm Tooling (EOAT) for your robot, remember these crucial points. They’ll help make your automation smooth and effective.

Pick Strong, Easy-Care Tools:

Choose tools that last. You need tough ones that won’t quit on you. Also, look for tools that are easy to fix and clean. Less hassle means your line keeps moving fast.

Think About Cost and Value:

Don’t just look at the price. Consider what the tool brings to your table. Sometimes, spending a bit more upfront gives you better quality and saves money down the road.

Safety First:

Your tool should be safe. Go for ones with safety features that meet your industry’s rules. Keeping your team safe avoids accidents and keeps costs down.

Make Sure It Fits:

Your EOAT needs to fit your robot perfectly. It should easily attach and talk to your robot’s system. A good fit means better work.

Consider Your Work Environment:

Where you work matters. If it’s really hot, cold, or wet, get a tool that can handle those conditions. The right tool works well, no matter where it is.

Keep these tips in mind to find the best EOAT for your robot. This way, you’ll boost your efficiency and keep things safe and smooth on your production floor.

Conclusion:

Picking the best End-of-Arm Tooling (EOAT) can really make a difference in your work. It’s all about choosing tools that last, offer good value, keep everyone safe, match your robot perfectly, and suit your work environment. This careful selection ensures your automation does exactly what you need, making your process smoother and safer. So, take your time to think about these important points.

The right EOAT will help your robots do their jobs better, making your production line more productive and safe. It’s about working smarter and getting the best results for your effort.

Want to learn more about End of Arm Tooling and boost your automation efficiency? Join our community at Qviro Community to connect with experts and get the insights you need!