Choosing the right gripper is like picking the perfect tool for an application. It’s not just about grabbing or holding; it’s about precision, efficiency, and making sure your robots can handle whatever task you throw at them. With options ranging from soft silicone to sturdy metal, the price tags can vary widely.

But don’t worry, we’re here to break it all down for you.

Let’s dive into understanding how these differences affect the cost and what that means for you, making sure you get the best bang for your buck.

Understanding Grippers:

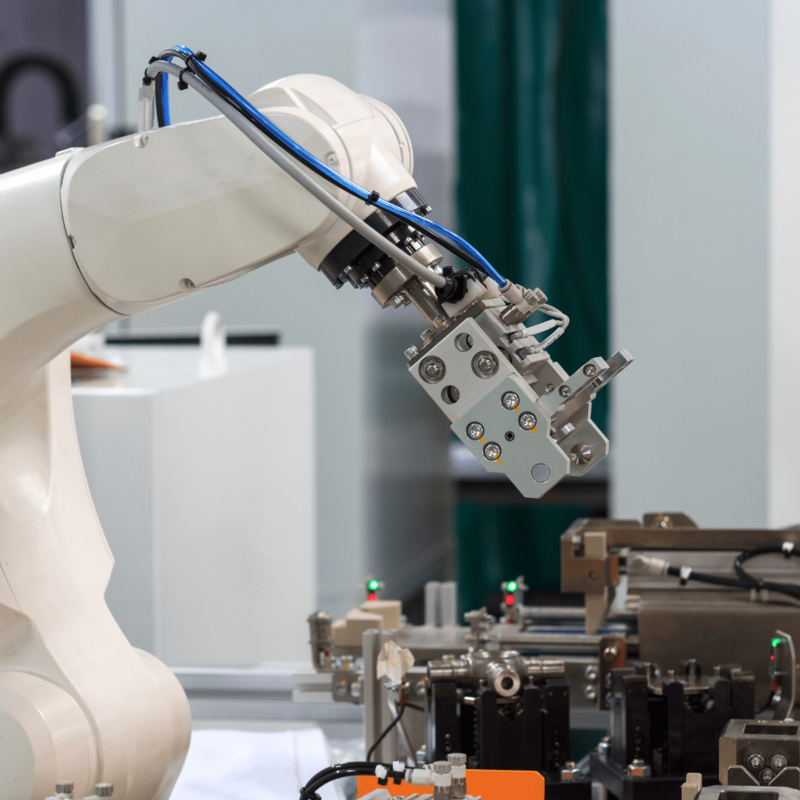

Robotic grippers are like the hands of a robot. They’re what make robots so handy in factories and workshops, letting them pick up, move, and manipulate all sorts of items with amazing accuracy. These grippers are key players in making tasks like putting things together, packing them up, or checking them over both fast and flawless. Think of them as the ultimate multitaskers, adaptable enough to switch from one job to another without breaking a sweat.

How Grippers Get the Job Done:

Grippers come in all shapes and sizes, designed to do just about anything you need. Whether it’s assembling tiny electronics with pinpoint precision, boxing up products at lightning speed, or sorting and inspecting parts with an eagle eye, grippers are up to the task. They’re the reasons robots can work so efficiently, often doing jobs faster and with fewer mistakes than humans. Plus, they’re incredibly versatile. With the right gripper, a robot can handle delicate glassware just as easily as it can move heavy metal parts. This flexibility is a game-changer for businesses looking to boost their production lines.

Types of Grippers:

Let’s break down the main types of grippers you’ll come across and what they’re best at.

- Pneumatic Grippers: These grippers are powered by air pressure. They’re like the strong, silent types—powerful yet simple. Pneumatic grippers are great for jobs that need a firm grip, like holding onto car parts as they’re assembled. They’re popular because they’re reliable and cost-effective, making them a go-to for many manufacturing tasks.

- Electric Grippers: These are the tech-savvy cousins of pneumatic grippers. Powered by electricity, they offer more control and precision. This makes them perfect for delicate or intricate tasks, such as picking up and placing small electronic components. Electric grippers are a bit pricier but worth the investment for jobs that require a gentle touch.

- Hydraulic Grippers: Think of hydraulic grippers as the heavy lifters. They use fluid power to operate, giving them the strength to handle big, heavy objects. If you’re moving large engine parts or steel beams, hydraulic grippers are your best bet. They’re tough and powerful, designed for the heaviest tasks on the production floor.

- Servo-Electric Grippers: These grippers are all about precision and versatility. They use servo motors to control their movement, allowing for very precise grips. This makes them ideal for tasks that need a delicate hand, like handling fragile items or performing complex assemblies. Servo-electric grippers are the high-tech option, offering the best in control and flexibility.

Material Matters: From Silicone to Metal

Choosing the right material for your robotic gripper is crucial. It’s all about finding the perfect balance between what you need the gripper to do and how much you’re willing to spend. From the soft touch of silicone to the firm strength of metal, each material offers something special.

Let’s explore what silicone and metal grippers bring to the table, as well as peek into other materials that might catch your eye.

Silicone Grippers:

Silicone grippers are the go-to when you need a light, gentle touch. Their flexibility and softness make them ideal for handling items that are delicate or easy to damage.

- Characteristics: Silicone is all about flexibility and safety. It can conform to the shape of the object it’s gripping, reducing the risk of damage.

- Typical Applications: These grippers shine in the food industry where handling without harming is key. They’re also stars in electronics assembly, where precision is absolutely important.

- Price Range: The price for silicone grippers can range from as low as $100 to $1,000 or more for highly specialized or custom models designed for specific applications.

Metal Grippers:

When you need a gripper that can take on heavy-duty tasks, metal is your best bet. Metal grippers are tough, durable, and built to last.

- Characteristics: Metal grippers are all about strength and precision. They can handle heavy loads and operate in environments that would wear down less sturdy materials.

- Typical Applications: Perfect for heavy manufacturing and the automotive industry, where moving large, heavy parts quickly and accurately is a daily demand.

- Price Range: Given their durability and the precision manufacturing required, metal grippers are generally more expensive. Prices can start from a few hundred dollars and go up to several thousand dollars, depending on the gripper’s complexity, precision, and strength. For industrial-grade metal grippers designed for heavy-duty or highly precise operations, costs can range from $500 to $5,000 or more.

Other Options:

While silicone and metal are popular choices, they’re not the only materials out there. Let’s look at a couple of other options:

- Plastic Grippers: Lightweight and cost-effective, plastic grippers are great for simple, repetitive tasks that don’t require a lot of force or precision. They’re often used in light assembly work and picking and placing small parts.

- Composite Material Grippers: These grippers combine materials to offer the best of both worlds. They can be as gentle as silicone but with the added durability of metal or plastic. This makes them versatile and suitable for a wide range of applications, from food handling to assembly lines where both strength and sensitivity are needed.

Each material has its own set of advantages and is suited to specific tasks. The key is to match the material to your needs, considering the nature of the items you’re handling, the environment in which the gripper will operate, and, of course, your budget. Whether you opt for the gentle touch of silicone, the sturdy reliability of metal, or something in between, the right material can make all the difference in your robotic automation setup.

![]()

Understanding Costs of Robotic Grippers:

Getting the right robotic gripper involves looking at price tags and understanding what goes into those costs. Let’s simplify how to see the price and make smart choices within your budget.

Price Factors:

- Materials: Grippers come in various materials, each with its own cost. Silicone grippers are usually cheaper, around $100 to $1,000. Metal grippers, known for their strength, can set you back $500 to $5,000.

- Tech Type: The technology behind the gripper affects the price. Pneumatic grippers are more budget-friendly, about $200 to $800. Electric ones, offering more control, start from $1,000 and can go up to $5,000.

- Brand Names: Sometimes, you pay extra for a well-known brand, but it might be worth it for the quality and support you get.

- Customization: If you need a gripper tailored for a specific job, expect to pay more. Custom features can increase the cost significantly.

Smart Budgeting:

- Match Needs with Costs: Define what you really need before shopping. This helps you avoid paying for fancy features you won’t use.

- Consider Long-Term Costs: A gripper’s purchase price is just the start. Think about maintenance and repair costs too. Sometimes, spending more at first can save money later.

- Check Compatibility: Ensure the new gripper works with your current robots to avoid extra costs for adjustments or new purchases.

By focusing on these points, you can pick a robotic gripper that does the job without overstretching your budget. It’s all about balancing what you need with what you’re willing to spend, considering both the initial cost and the long haul. This way, you invest in a solution that brings value to your operations for years to come.

Making an Informed Buying Decision:

Choosing the right robotic gripper isn’t just about price; it’s about ensuring it meets your specific needs and integrates seamlessly with your existing systems. Let’s guide you through the essential considerations and how to effectively assess the market for your perfect match.

Key Considerations:

- Robot Compatibility: Make sure the gripper you pick can easily connect with the robots you already use. This saves you from compatibility headaches or extra costs down the line.

- Operational Environment: Your work environment matters. Whether it’s hot, dusty, or wet, choose a gripper that can handle these conditions without faltering.

- Object Type: What are you planning to pick up? Different grippers excel with different materials. Ensure your choice is up to the task, whether it’s delicate electronics or heavy metal parts.

- Precision Needed: Accuracy is key for many tasks. If your work requires high precision, look for grippers known for their control and accuracy.

Assessing the Market:

- Compare Products: Don’t settle on the first option. Look around and compare different grippers. Pay attention to features, prices, and reviews to find the best fit.

- Emerging Technologies: Stay open to new advancements. The latest tech might offer better efficiency or capabilities at a good price point.

- Find Reliable Reviews: Research is your friend. Look for product reviews and benchmarks from trusted sources. Online forums, industry publications, and user testimonials can provide valuable insights.

Remember, choosing a robotic gripper is a significant decision that impacts your production efficiency and effectiveness. By considering these key aspects and carefully assessing your options, you can make an informed choice that not only fits your immediate needs but also positions you well for future advancements. The goal is to invest in a solution that delivers on performance, compatibility, and value, ensuring your manufacturing line runs smoothly and efficiently.

Installation and Maintenance:

Once you’ve picked the right robotic gripper, whether it’s made of silicone, metal, plastic, or a composite, the journey doesn’t end there. Setting it up properly and keeping it in good shape are crucial steps to make sure it keeps up with your demands. Let’s dive into the essentials of installation and ongoing maintenance.

Getting Your Gripper Up and Running:

- Face the Installation Challenge: Fitting your new gripper onto your robot can be tricky. It’s all about making sure they work together smoothly.

- Tips for a Smooth Setup: Always start with the manual—it’s there to help. Use any setup software provided to ease the process. If things get tough, don’t hesitate to call the manufacturer’s support team for help. For complex setups, considering a pro installer could save you time and headaches.

Keeping Your Gripper in Top Shape:

- Routine Checks: Like any tool, your gripper needs regular love and care. This means cleaning it, checking for parts that need oil, and keeping an eye out for signs of wear.

- Dealing With Wear and Tear: All grippers wear down eventually. Check yours often for any issues and replace parts as needed. For grippers made of softer materials like silicone or plastic, watch for splits or stretches. For those made of harder stuff like metal or composites, look out for rust or damage.

- Updates Matter: If your gripper uses software, keep it up to date. Updates can boost performance, introduce new features, and fix bugs.

Proper setup and regular maintenance are key to making sure your robotic gripper works well for a long time. By taking these steps, you’ll keep your production line moving smoothly and avoid unexpected downtime. A bit of effort in keeping things running right can save you a lot of trouble later on.

Conclusion:

Choosing the right gripper is about more than just today; it’s planning for the future. The type and material should fit your current needs and be ready for what comes next. Spending a little more now on the right choice can save you money and hassle later as technology changes. Ready to find your ideal gripper?

Do You Need to Compare Different Gripper Models?