When it comes to improving your manufacturing line, understanding linear motion systems is crucial. These systems are the backbone of many automated processes, ensuring precise and efficient movement along a straight path. From CNC machines to medical devices, linear motion systems play a vital role in various industries.

This article will guide you through the basics of linear motion, explore different types, and help you select the right system for your needs. By the end, you’ll have a solid foundation to make informed decisions and enhance your automation projects.

What are Linear Motion Systems?

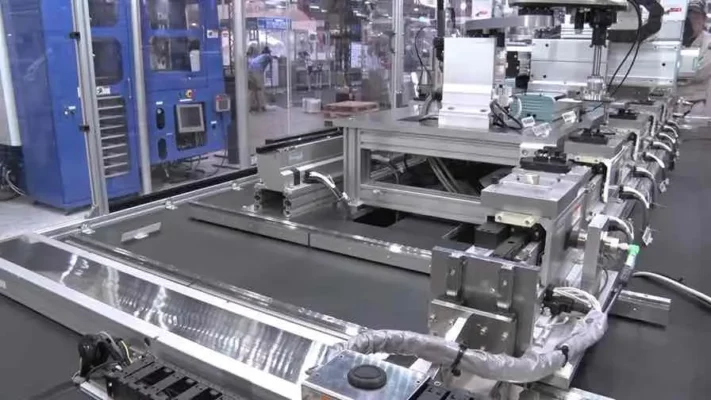

Linear motion is the movement of a load in a straight line. It’s vital for many automated processes in your manufacturing line. Linear motion systems include components like guides, rails, and actuators, which help achieve this straight-line movement.

Basic Principles & Mechanics:

Linear motion works by converting rotational motion into straight-line movement. This is often done with ball screws or belt drives that turn motor rotation into linear travel. Bearings and lubricated surfaces reduce friction, ensuring smooth and precise motion.

Difference between Linear & Rotational Motion:

Linear motion moves objects in a straight path, while rotational motion spins objects around an axis. You use linear motion for tasks like CNC machining or sliding doors. Rotational motion is for things like motor shafts or gears. Knowing the difference helps you choose the right system for your needs.

Types of Linear Motion Systems:

Ball Screw Systems:

Ball screw systems use a screw mechanism to convert rotational motion into linear motion. They are ideal for high-precision tasks like CNC machines and robotics.

Pros and Cons Pros: High accuracy, load capacity, and efficiency. Cons: Can be expensive and require regular maintenance.

Belt-Driven Systems:

Belt-driven systems use a belt and pulley to achieve linear motion. They are common in conveyor systems and low-load applications.

Pros and Cons Pros: Cost-effective and low maintenance. Cons: Limited precision and load capacity.

Linear Motors:

Linear motors provide direct linear motion without mechanical conversion. They are used in high-speed and high-precision applications like semiconductor manufacturing.

Pros and Cons Pros: High speed, precision, and minimal maintenance. Cons: Higher cost and complexity.

Components of Linear Motion Systems:

Rails and Guides:

Rails and guides are typically made from hardened steel or aluminum. They provide stability and precision to the system. It ensures smooth and accurate movement, essential for high-precision tasks.

Bearings:

Ball bearings and roller bearings. Bearings reduce friction, enhancing the efficiency and lifespan of your linear motion system.

Actuators:

Electric, pneumatic, and hydraulic actuators. Choose based on speed, load capacity, and environmental conditions. Electric actuators offer precision, pneumatic ones are cost-effective, and hydraulic actuators handle heavy loads.

Applications of Linear Motion Systems:

Manufacturing & Automation:

CNC Machines: You’ll find linear motion systems in CNC machines, ensuring precise cutting, drilling, and shaping.

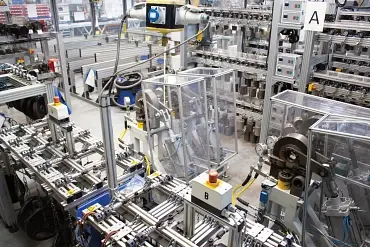

Robotics: Linear motion is crucial for robotic arms, providing accurate and repeatable movement in assembly lines and material handling.

Medical Equipment:

Imaging Devices: Linear motion systems enhance the precision of imaging devices like MRI and CT scanners, improving image quality.

Surgical Robots: In surgical robots, linear motion ensures precise and controlled movements, enhancing the accuracy of minimally invasive surgeries.

Transportation & Logistics:

Conveyor Systems: Linear motion systems are used in conveyor belts, moving products efficiently through your production line.

Automated Storage and Retrieval Systems: These systems use linear motion to quickly and accurately store and retrieve items in warehouses, boosting efficiency and reducing labor costs.

Benefits of Linear Motion Systems:

1. Precision & Accuracy:

Linear motion systems provide precise and accurate movements. This ensures your machinery operates with exact measurements, crucial for tasks like CNC machining and medical equipment where precision matters.

2. Efficiency & Speed:

These systems boost your efficiency and speed. By reducing friction, they allow for smooth and fast movements. In conveyor systems and automated storage, they help you complete tasks quickly, saving you time.

3. Versatility in Various Applications:

Linear motion systems are highly versatile. You can use them in a wide range of applications, from manufacturing and automation to medical devices and logistics. This adaptability makes them a valuable tool for many industries.

How to Select the Right Linear Motion System:

Assessing Application Requirements:

Load Capacity: Determine the load capacity you need. This is the maximum weight your system will handle. Make sure the system can support your heaviest loads to avoid issues.

Speed & Acceleration: Consider the speed and acceleration required for your application. High-speed tasks need systems that can move quickly without losing precision. Check the specifications to match your needs.

Environmental Conditions: Evaluate the conditions where the system will operate. If you’re working in extreme temperatures, dusty, or wet environments, choose a system designed to withstand those conditions. This ensures reliability and longevity.

Comparing Specifications:

Load Ratings: Check the load ratings to ensure the system can handle your required weights.

Travel Length: Ensure the system’s travel length fits your application’s movement range.

Maintenance Needs: Evaluate maintenance requirements. Choose systems that are easy to maintain to minimize downtime.

Key Manufacturers & Brands:

Vansichen:

Vansichen specializes in advanced linear motion solutions, offering high-quality single-axis systems designed for precision and reliability. Their products are well-suited for various automation applications.

Yamaha:

Yamaha provides robust and versatile linear motion systems, including electric actuators and linear guides. Known for their durability and performance, Yamaha’s products are ideal for demanding industrial environments.

ABB:

ABB offers innovative linear motion systems that integrate seamlessly with their automation solutions. Their products are known for high precision, efficiency, and ease of integration into complex manufacturing processes.

IGUS:

IGUS is renowned for its cost-effective and high-performance linear motion systems. They offer a wide range of products, including drylin® linear guides, known for their maintenance-free and lubrication-free operation.

KUKA:

KUKA is a leading provider of linear motion systems, known for their high-performance actuators and guides. Their solutions are designed to meet the rigorous demands of industrial automation and robotics.

Conclusion:

Linear motion systems are crucial for improving precision and efficiency in your automation processes. To select the right system, assess your needs like load capacity, speed, and environmental conditions. Compare specifications and consider maintenance requirements to ensure a good fit. Keep an eye on future trends and innovations in linear motion technology, as they promise enhancements in speed, accuracy, and versatility. By making informed choices, you can optimize your manufacturing processes and stay competitive in your industry.