In the realm of industrial automation, SCARA robots have become quite popular due to their versatility and advantages. But what exactly is a SCARA robot, and how does it work? In this comprehensive guide, we will explore the fundamentals of SCARA robots, their benefits, drawbacks, and why they can be a wise choice for automating various tasks.

What is a SCARA Robot?

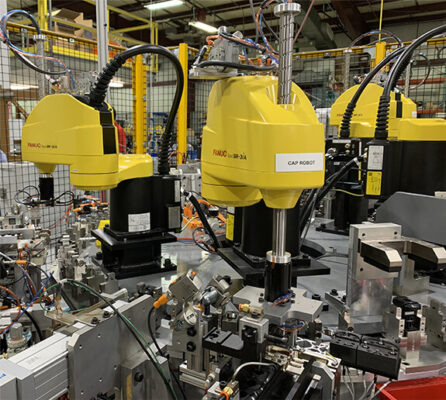

A SCARA robot is a special kind of robot that’s used in factories and other places to do tasks that need a lot of precision. Unlike regular robots, SCARA robots can move their arms in different ways, kind of like a human arm. They have four parts in their arm that can move, so they can go side to side (like left and right), up and down, and spin around in a circle.

The name “SCARA” might sound tricky, but it stands for “Selective Compliance Articulated Robot Arm.” What this means is that these robots are good at being flexible and can adjust how they move to fit the job they’re doing.

SCARA robots are really helpful because they’re fast, precise, and they can handle different tasks. For example, they can put together small electronic parts, move items around on a production line, or do things that require a delicate touch. Their ability to be flexible and move precisely makes them stand out and be useful in many industries. So, in simple terms, a SCARA robot is a special kind of robot that’s great at doing jobs with accuracy and speed.

How do SCARA Robots Work?

SCARA robots generally have four ways they can move, which allows them to do many different tasks effectively. These four movements are:

- X-direction: Imagine moving your hand left and right – that’s like the X-direction for a SCARA robot. It lets them reach out to the sides.

- Y-direction: If you move your hand forward and backward, that’s similar to the Y-direction for a SCARA robot. It helps them reach things in front of them or pull back when needed.

- Z-direction: Moving your hand up and down is just like the Z-direction for a SCARA robot. It lets them adjust their height, which is handy for picking things up or placing them down at different levels.

- Rotation around the Z-axis: Now, think about turning your hand in a circle without moving it up or down – that’s what SCARA robots can do when they rotate around the Z-axis. This helps them twist or turn things as required.

Applications of SCARA Robots:

SCARA robots are used in many industries, like making electronics, cars, metal products, plastic items, and more. They are also used in making food, medicines, and cosmetics. Basically, anywhere that needs things to be made very precisely and quickly, SCARA robots can be a big help.

Advantages of Using SCARA Robots:

SCARA robots have some benefits that make them a good choice in many workplaces:

1. Speed & Precision:

One of the main benefits of SCARA robots is their impressive speed and precision. Thanks to their simple movements, these robots can finish tasks quickly and accurately. This means things can be made faster, and there are fewer mistakes.

2. Compact Size & Cost-Efficiency:

SCARA robots are known for being small, which is great when there’s not much space in a factory. Also, they don’t cost as much as some other robots, so businesses can use them without spending too much money.

3. Easy To Fit In:

SCARA robots can easily fit into existing systems, so factories don’t have to change everything to use them. Also, they are getting smarter and can learn new things to help with production.

Disadvantages of Using SCARA Robots:

While SCARA robots are pretty amazing, they do have some limits:

1. Can’t Lift Heavy Things:

SCARA robots are best for jobs that don’t need to lift very heavy things. They are usually good with things that weigh from half a kilogram to 20 kilograms. For really heavy things, other types of robots are better.

2. Not for Big Spaces:

SCARA robots have a small working area because of how they move. This can be a problem if a job needs a lot of space to move around. In those cases, different robots are a better fit.

Why It’s a Good Time to Consider SCARA Robots?

Lately, there have been big improvements in how robots work, and SCARA robots are becoming even more helpful. They are getting better at doing different jobs, thanks to things like computers and the internet. This means they can be a big help in making things more efficiently.

Choosing the Right SCARA Robot for Your Needs:

When picking the right SCARA robot, there are a few things to think about:

1. What You Need:

Think about what you want the robot to do. Is it for making electronics, moving things around, or something else? This helps you find the right robot that can do the job.

2. Where It Will Go:

Consider where the robot will work. Is there enough space? Does it fit with other machines? This is important to make sure the robot can do its job well.

3. How It Will Learn:

Check if the robot can learn and change as needed. This is handy if the job changes or if you want the robot to do new things later.

4. Try Before You Buy:

It’s a good idea to test the robot in a simulator first. This helps you see if it works well before you spend money on it.

Market Insights & Trends:

1. Market Size:

The worldwide SCARA robot market is getting bigger, and it’s expected to reach “$10.4 billion by 2024”. This means more and more people are using SCARA robots.

2. Key Players:

Some of the big companies in the SCARA robot market include Seiko Epson Corporation, Kawasaki Robotics, ABB, OMRON Corporation, Mitsubishi Electric Corporation, KUKA AG, Fanuc Corporation, DENSO Corporation (DENSO Robotics), Yaskawa Electric Corporation, and Stäubli International AG (Allied Market Research, 2020).

3. Different Jobs:

SCARA robots are now doing all kinds of different tasks in many places. One area where they’re getting used a lot is in precision engineering and optics. In simple words, they’re good at handling tiny, delicate things and putting them together very carefully.

4. How Much They Can Carry and What They Can Do:

In the world of SCARA robots, robots come in different groups based on how much they can carry. Some can handle light things, while others can manage moderately heavy objects. People often use them for tasks like putting things together or taking them apart quickly and accurately.

5. Future Trends:

In the future, SCARA robots will work closely with people in factories. They will get better at seeing things and become smarter in learning new tasks. This will make them even more useful for various jobs. These changes indicate an exciting future for SCARA robots, confirming their significance in manufacturing.

Conclusion:

In conclusion, SCARA robots, with their unique features and versatility, have become indispensable in various industries. As the world of automation continues to evolve, SCARA robots are poised to play an even more significant role in shaping the future of manufacturing. Whether you are considering adopting SCARA robotics or simply want to stay informed about the latest trends in industrial automation, this guide has provided valuable insights into the world of SCARA robots.

To learn more about SCARA Robots.

Are you looking for a System Integrator?

Visit Qviro