AGS Attendance Check Specifications

Ranked Nr. 48 of 235 Grippers

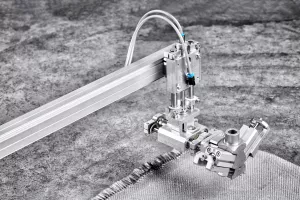

The AGS Automation Attendance Check is a specialized system designed for industrial automation that provides accurate and efficient attendance monitoring. It is equipped with advanced sensors and cameras that are capable of detecting and identifying individuals, making it ideal for a variety of applications in manufacturing, logistics, and other industries. In this section, we will discuss some of the key features and applications of the AGS Automation Attendance Check.

One of the standout features of the AGS Automation Attendance Check is its ability to accurately identify and track individuals. The system uses advanced facial recognition technology that can quickly and accurately identify individuals and record their attendance. This makes it an ideal solution for applications where attendance tracking is essential, such as in manufacturing plants, warehouses, and other industrial settings.

The AGS Automation Attendance Check is also designed to be highly customizable and flexible, allowing it to be tailored to specific applications and requirements. It can be integrated with a variety of software systems, making it easy to integrate into existing automation workflows and processes. The system can also be customized to support a wide range of sensors and cameras, allowing it to be adapted to different environments and applications.

Another key feature of the AGS Automation Attendance Check is its ability to operate in a wide range of environments and conditions. It is designed to be highly durable and rugged, making it suitable for use in harsh industrial environments. It is also capable of operating in extreme temperatures, making it an ideal solution for applications in environments where temperature fluctuations are common.

In addition to its primary application in attendance monitoring, the AGS Automation Attendance Check can also be used for a variety of other applications in industrial automation. For example, it can be used for flow monitoring, allowing it to accurately track the movement of materials and goods through a manufacturing process. It can also be used for security monitoring, providing real-time monitoring of critical areas and detecting potential security threats.

In conclusion, the AGS Automation Attendance Check is a highly advanced and customizable system that provides accurate and efficient attendance monitoring in industrial automation applications. Its advanced facial recognition technology, flexibility, and durability make it an ideal solution for a wide range of applications, including attendance monitoring, flow monitoring, and security monitoring. Its ability to operate in extreme temperatures and compatibility with a wide range of sensors and cameras make it a unique and valuable option for industrial automation.

| Repeatability | 0.01 mm |

| Max. Force | 200 N |

| Min. Force | 10 N |

| Max. Stroke | 60 mm |

| Energy source |

|

| Operation type |

|