AGS Parts Inspection Specifications

Ranked Nr. 48 of 235 Grippers

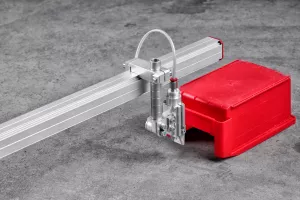

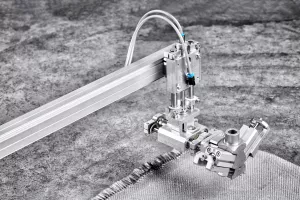

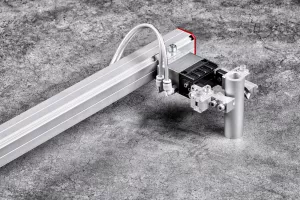

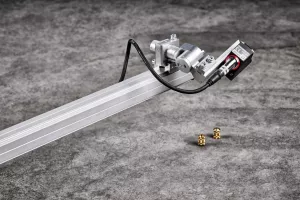

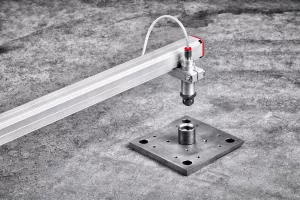

AGS Automation's part controls TEK is a useful feature for monitoring the presence of components in the gripper. When vacuum suction cup monitoring is not possible, the TEK system comes in handy. It ensures that the components are correctly in place before they are picked up, avoiding any potential issues in the production line.

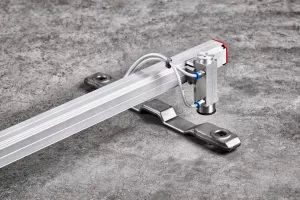

With a variety of accessories available in the program, including mounting material, cables, plugs, and distributors, the TEK system can be customized to fit the specific needs of different applications. This allows for easy integration with other components in the automation system and simplifies the installation process.

The TEK system is ideal for applications that require precise component placement and handling, such as in the electronics and semiconductor industries. It ensures that the right components are picked up and placed in the correct orientation, improving production efficiency and reducing the likelihood of errors.

Overall, AGS Automation's part controls TEK is a reliable and efficient solution for monitoring the presence of components in the gripper, providing added accuracy and precision to various manufacturing processes.

| Energy source |

|

| Operation type |

|

| Application |

|

| Industry |

|