AGS Vacuum Pads Specifications

Ranked Nr. 48 of 235 Grippers

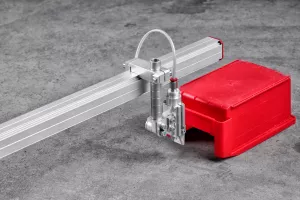

AGS Automation's vacuum pads, specifically the suction pad (vacuum cup) SG, are a reliable and cost-effective solution for handling components. With various designs, materials, and sizes available, these vacuum pads can be customized to fit the needs of any application. The suction pad SG can be attached directly to a profile, making it a great option for a range of industries.

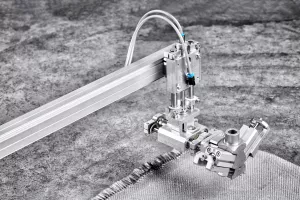

The simplicity of the suction pad SG is what makes it such an appealing option for many manufacturers. It works by creating a vacuum between the pad and the component being handled, allowing for a secure grip. This process is reliable and can be repeated over and over again without any loss of suction.

In addition to the standard design, there are various other designs available to suit specific needs. For instance, a rigid suction pad can be used for components that require a sturdier grip, while a twistable suction pad is ideal for components that need to be rotated during the handling process. There are also spring-loaded suction pads that can adapt to components with varying shapes and sizes.

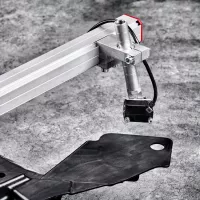

One of the key benefits of AGS Automation's vacuum pads is their ability to be used in conjunction with a lifting unit. This allows for components to be lifted and transported without the need for manual labor. The lifting unit can be controlled by a remote, making it easy to maneuver the components into the desired position.

The materials used to make these vacuum pads are also customizable. This allows them to be used in a range of environments, from cleanrooms to harsh manufacturing settings. Different materials can be used for different applications, ensuring that the suction pad SG is a versatile solution for a variety of industries.

In summary, AGS Automation's vacuum pads are a reliable and cost-effective solution for handling components. The suction pad SG is the simplest and most common type of vacuum pad, with various designs, materials, and sizes available. It can be attached directly to a profile or used in conjunction with a lifting unit, making it a versatile option for a range of industries.

| Payload | 100 kg |

| Industry |

|

| Application |

|

| Operation type |

|

| Energy source |

|