Brovind Step-feeder Alternatives & Competitors

Ranked Nr. 101 of 98 Robot Accessories

Top 10 Step-feeder Alternatives

- Brovind Vibrating drive units for circular feeders

- Brovind Cylindrical bowls for vibrating feeders

- TAD Bowl Feeders Special configurations

- TAD Bowl Feeders Autonomy unit with elevation

- TAD Bowl Feeders Superimposed autonomy unit

- RNA Vibration Platform FlexType P

Brovind Vibrating drive units for circular feeders

FeedersBrovind's vibrating drive units are designed to generate the necessary vibration required for feeding and orienting parts inside prepared bowls. These units are essential components of circular feeders, which are widely used in various manufacturing and assembly processes to automate the feeding and orientation of small parts.

The vibrating drive units manufactured by Brovind are powered by an electromagnet and are controlled by an electronic controller. The controller allows for precise adjustments to the vibration frequency and intensity, ensuring that the parts are fed and oriented accurately and reliably. Additionally, these units can be fitted with a sensor, which allows for real-time monitoring and offsetting of vibration parameters, further enhancing their accuracy and reliability.

The standard power supply for Brovind's vibrating drive units is single-phase 230V, 50 Hz, which is compatible with most industrial power systems. However, these units can also be supplied with different voltages and frequencies to meet specific requirements.

One of the main advantages of Brovind's vibrating drive units is their versatility. They can be easily integrated into existing manufacturing and assembly lines and are compatible with a wide range of parts and feeders. They are also designed to be low-maintenance, with a long service life, ensuring maximum uptime and productivity.

In conclusion, Brovind's vibrating drive units are an essential component of circular feeders, providing reliable and accurate vibration necessary for feeding and orienting small parts. With their electronic controllers, sensor options, and versatility, these units offer a cost-effective and efficient solution for automating manufacturing and assembly processes.

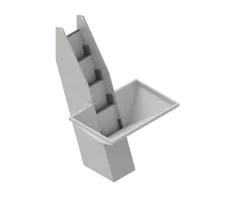

Brovind Cylindrical bowls for vibrating feeders

FeedersBrovind's Cylindrical Bowls are designed to contain and direct parts for feeding and orienting with their circular vibratory bases. Available in standard AISI 304 stainless steel or polyamide versions, these bowls can also be customized based on specific needs such as material (e.g., AISI 316 stainless steel) and dimensions (coil width, pitch, etc.). Additionally, they can be coated with wear-proof or oil-proof materials for added durability. These bowls are an essential component of Brovind's high-quality vibrating feeders, delivering reliable and efficient feeding and orientation of parts in various industrial applications.

RNA Vibration Platform FlexType P

FeedersFlexType P offers you a pre-configured feeding system adapted to your parts that is based on our FlexCube vibration platform with hopper, parts recirculation and camera system.

FlexType P features an integrated vibration platform. Specific movements can be programmed in the x, y and z directions on the vibration platform. Taking into account their properties, parts are therefore handled in such a way that a high number of parts are ready to be picked up. This enables higher feeding capacities compared to uncontrolled vibration platforms. By offering freely programmable flipping amplitudes, it even allows to place elongated parts upright, or to fill pockets mounted directly onto the platform.

Based on a modular system, RNA also offers dual systems, as illustrated, with two platforms operating independently in parallel. Models with hopper, quick emptying system and parts recirculation for short changeover times are optionally available. Possibility of combining different robot and control systems or handling gantries.