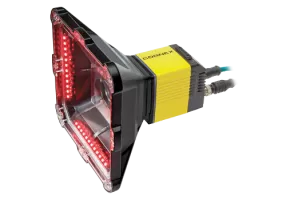

COGNEX DataMan 7905 Barcode Verifier Specifications

Ranked Nr. 293 of 126 2D Vision Systems

The COGNEX DataMan 7905 Barcode Verifier is a versatile solution that combines powerful vision technologies with proven verification methods, allowing users to perform inspections and grade the quality of codes simultaneously. It eliminates the need for multiple devices or custom solutions by offering integrated dimensioning, optical character recognition (OCR), and verification tools. This enables users to automate multiple tasks with ease, making it ideal for various applications requiring code quality control.

One of the standout features of the In-Sight 7905V is its ISO compliance, supporting ISO/IEC standards 15415, 15416, 29158, 15426-1, and 15426-2. This compliance ensures that the verifier meets the most demanding application requirements, making it suitable for highly regulated industries like medical devices and pharmaceuticals. The pre-configured lighting, calibration card, and robust grading algorithms contribute to accurate and repeatable grading results, enhancing its reliability and efficiency.

Additionally, the In-Sight 7905V offers advanced verification, vision, and diagnostic tools, providing a flexible all-in-one solution. Users can grade 1D and 2D codes, decipher human-readable text, and confirm correct code placement on parts. This combination of capabilities not only streamlines operations but also allows for the identification and resolution of quality issues. Furthermore, the verifier supports 21 CFR Part 11 compliance, crucial for the pharmaceutical and medical industries, by generating reports that detail data changes and user logins, ensuring accountability and traceability in managing electronic documents.

| Industry |

|

| Type |

|