Elephant Robotics Adaptive Gripper Pro Specifications

Ranked Nr. 7 of 235 Grippers

领先的先进机器人解决方案提供商 Elephant Robotics 最近推出了其最新产品 Adaptive Gripper Pro。该产品是该公司之前自适应夹持器型号的升级版,具有出色的夹紧力和多功能性,是各种工业自动化应用的理想解决方案。

Adaptive Gripper Pro 最显著的特点之一是其夹紧力增强。这款夹持器的最大夹紧力可达 1000g,能够处理各种物体,从精密部件到较重的物品。夹持器夹紧力增强是由于采用了新的齿轮减速机构,可提供更好的扭矩和夹紧力。

除了增强的夹紧力外,Adaptive Gripper Pro 还支持多种编程环境,使其与各种工业机械臂兼容。这款夹持器可以使用行业标准软件进行编程,包括 ROS、Python 和 C++。这种灵活性使用户能够轻松地将 Adaptive Gripper Pro 集成到现有的自动化系统中,使其成为各种应用的经济高效的解决方案。Adaptive

Gripper Pro 的另一个显著优势是其适应性。夹持器采用模块化设计,允许用户根据特定需求快速轻松地更换不同的夹持模块。这种模块化设计使 Adaptive Gripper Pro 成为需要处理多个不同形状和大小的物体的应用的绝佳选择。

Choose your model:

Electric Parallel Gripper

Payload 0.1kg | Angular | Parallel

Pneumatic Gripper Pro with Air Compressor

Payload 1kg | Angular | Parallel

Pneumatic Gripper Pro without Air Compressor

Payload 1kg | Angular | Parallel

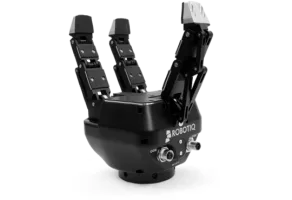

Adaptive Gripper Pro

Payload 1kg | "Angular | Parallel"

Adaptive Gripper

Payload 0.15kg | Angular | Soft

| Energy source |

|

| Operation type |

|

| Application |

|

| Industry |

|

| Payload | 1 kg |

| Max. Stroke | 90 mm |

| Gripper mass | 0.35 kg |