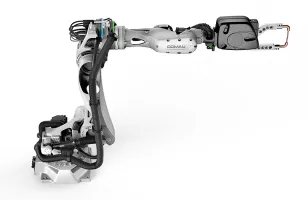

FANUC M-20iB/25 Specifications

Ranked Nr. 11 of 408 Industrial (Articulated) Robots

The FANUC M-20iB/25 is a versatile industrial robot designed for a wide range of manufacturing applications. It features a 25 kg payload capacity and a reach of 1853 mm, making it suitable for various tasks requiring precision and agility. The robot is equipped with six controlled axes and boasts a repeatability of ±0.02 mm, ensuring high accuracy in operations. Its fully enclosed construction adheres to the IP67 standard, providing robust protection against wet, dirty, and harsh environments, which is particularly beneficial for applications such as automatic deburring.

One of the standout features of the M-20iB/25 is its lightweight hollow upper arm and wrist, combined with advanced servo technology. This design innovation allows for faster cycle times and increased throughput, enhancing overall performance. Compared to its predecessor, the M-20iA, the M-20iB/25 offers a 25% increase in payload capacity and a 21% increase in axis speeds. The fully encapsulated design ensures that cables and motors are not exposed, reducing interference and enhancing reliability. Additionally, the connectors are streamlined along the arm, further minimizing potential disruptions.

The M-20iB/25 is well-suited for demanding environments and various industrial applications. Its flexibility in mounting options, including floor, upside-down, and angle, allows for easy integration into different setups. This robot is ideal for tasks such as assembly, arc welding, pick/pack/palletizing, load/transfer, material removal, and dispensing. Furthermore, it integrates seamlessly with FANUC's ROBOGUIDE offline programming software, enabling users to design cells, systems, and motions efficiently before actual deployment, thus optimizing planning and implementation processes.

| Application |

|

| Industry |

|

| Payload | 25 kg |

| Reach | 1853 mm |

| Repeatability | 0.02 mm |

| Number of Axes | 6 |