Grip MGW Connector Specifications

Ranked Nr. 94 of 116 End of Arm Tools

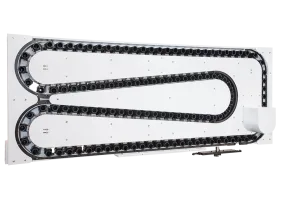

The MGW Connector is our universal quick changer for every application and we have made it even better! The new system is of higher quality and offers more safety and accuracy. The innovations are a response to the current requirements of our customers. A centering disc can be installed on both the upper assembly (robot side) and lower assembly (tool side) of the robot and ensures that the tools are correctly aligned with the robot arm.

MGW Connector advantages:

- Interface according to DIN EN ISO 9409-1

- Durable - 5,000/10,000 cycles*

- Withstands high loads

- No tool required due to integrated operating lever

- Intuitive operation

- Can be released and closed with one hand

- Protection against unintentional opening for dynamic applications

- Spring-loaded locking pin secures hand lever against self-releasing

- Lightweight made of high-strength aluminum, anodized

- Optional mounting surface for energy feed-through

*Cycles dependent upon the MGW material.

By turning the semi cylindrical bolt by 180°, the upper assembly and lower assembly are secured together. When locking, the lower assembly is pulled up by the lever action. A centering disc can be installed on both the upper assembly (robot side) and lower assembly (tool side) of the robot and ensures that the tools are correctly aligned with the robot arm.

| Payload | 10-120 kg |

| Product mass | 0-10.5 kg |

| Repeatability | 0 mm |