HAN’S ROBOTS S20 Alternatives & Competitors

Ranked Nr. 64 of 207 Cobots

Top 10 S20 Alternatives

- UNIVERSAL ROBOTS UR30

- DOOSAN M0617

- HAN’S ROBOTS S25

- PRODUCTIVE ROBOTICS OB7 MAX 8

- TECHMAN ROBOT TM25S

- DOBOT CR20A

- Neura Robotics MAiRA L

- FANUC CRX-25iA

- KASSOW ROBOTS KR1205

- ELITE ROBOTS CS66

- JAKA ZU 12s

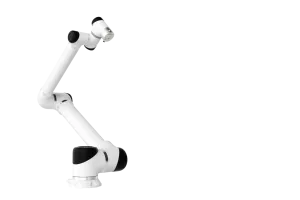

UNIVERSAL ROBOTS UR30

Payload 30kg | Reach 1300mmThe UR30 can lift heavy loads while maintaining a small footprint in a collaborative environment.

With a lifting capacity of 30kg and a reach of 1300mm, this robot can handle larger machines, palletize heavy products and effectively support high-torque screwdriving.

DOOSAN M0617

Payload 6kg | Reach 1700mmDoosan's M0617 cobot is an advanced collaborative robot designed to help workers perform tasks with ease and precision. This cobot has a maximum reach of 850 mm and a payload capacity of up to 6 kg, making it perfect for a wide range of applications, including assembly, testing, and packaging.

The M0617 cobot is equipped with six high-tech torque sensors in every joint, ensuring superior safety and collision sensitivity while providing human-level dexterity in automation. It offers a range of safety features, including emergency stop buttons, safety barriers, and collision detection technology, to protect workers and prevent accidents.

This cobot is also designed to be user-friendly and intuitive, with an easy-to-use programming interface and the ability to quickly switch between tasks. The M0617 cobot can be programmed to work alongside human workers in a variety of settings, increasing productivity and efficiency while reducing the risk of injury.

In addition to its standard capabilities, the M0617 cobot can be customized to meet specific industrial automation needs. It is compatible with a range of software systems, including Doosan's proprietary control software, and is capable of operating in extreme temperatures, making it suitable for use in harsh environments.

HAN’S ROBOTS S25

Payload 25kg | Reach 1800mmThe Han's Robot S series collaborative robot is a powerful industrial automation tool, designed to handle heavy loads with ease. With an impressive payload capacity ranging from 20kg to 25kg and a working radius of 1700mm to 1800mm, it's well-suited for tasks such as machine loading and unloading, palletizing, assembly, and heavy load handling. What sets the S series apart is its emphasis on performance, safety, and versatility. It boasts a rapid response time, with real-time control refresh frequencies of 1000/5000 Hz, ensuring precision in complex tasks. Additionally, it offers advanced safety configurations, making human-machine collaboration more secure and reliable.

This collaborative robot offers a low barrier to entry, enabling users to quickly learn and implement programming methods, making it accessible for a wide range of applications. Its modular design allows for easy customization to meet specific customer needs, facilitating flexible deployment and straightforward maintenance. The Han's Robot S series is an ideal choice for industries seeking to enhance productivity and efficiency while ensuring the safety of their workforce. Its heavy payload capacity and long reach make it a versatile tool for addressing various industrial automation challenges.

TECHMAN ROBOT TM25S

Payload 25kg | Reach 1902mmThe Techman Robot TM25S is a heavy-duty collaborative robot (cobot) belonging to the TM AI Cobot S series. With a remarkable payload capacity of 25 kg, it stands out as an ideal choice for industrial automation tasks that require lifting and moving heavy objects. Its impressive 1902 mm reach allows it to access a wide workspace, making it suitable for a range of applications such as massive pick and place operations, machine tending, high-volume packaging, palletizing, and more.

One of the standout features of the TM25S is its significantly enhanced speed and precision. It operates 25% faster than its predecessor, with the 6th axis joint speed increased from 225 °/s to 450 °/s. This boost in speed translates to a 25% reduction in cycle time, improving overall production efficiency. Moreover, the cobot offers exceptional repeatability accuracy, boasting a best-in-class ±0.03 mm precision, which is up to 70% more accurate than previous versions.

In terms of safety, the TM25S is equipped with up to 31 safety functions certified by TÜV, prioritizing safety in various automation scenarios. These functions align with the latest ISO standards, ensuring compliance with ISO 10218-1 and certification as PL d, Cat.3 according to ISO 13849-1. The cobot also holds safety certifications such as UL and CSA for North America and CE for Europe, making it a versatile and safe choice for industrial automation across different regions. Its flexibility in safety functions reduces the need for additional safety PLC, simplifying safety control configuration and assessments while enhancing overall workplace safety.

DOBOT CR20A

Payload 20kg | Reach 1700mmThe Dobot CR20A is a collaborative robot designed for heavy-duty industrial tasks, featuring a 1,700 mm working radius and a maximum payload of 20 kg. Its robust build makes it suitable for applications like picking, packing, palletizing, and welding across industries such as automotive, home appliances, logistics, and metal processing. The robot's ability to handle larger and heavier objects enhances its effectiveness in demanding environments.

One notable feature of the CR20A is its dual-channel end effector design, which supports multiple end tools simultaneously, allowing for greater operational flexibility. The robot includes a visual status indicator at its base, providing real-time monitoring of its operational state and simplifying performance tracking. This design facilitates faster deployment and easier user interaction.

The CR20A integrates advanced motion control algorithms that reduce residual vibrations by 50% during high-speed stops, ensuring stable and precise operations. Its extensive connectivity options include 24 interface ports supporting Profinet and Ethernet/IP, along with 24 digital IO ports for PNP and NPN switching, making it highly adaptable to various applications. The robot also features high protection levels (IP54) and safety mechanisms like an electromagnetic brake protection system, ensuring safe operation even during power failures.

Neura Robotics MAiRA L

Payload 12kg | Reach 1600mmThe Neura Robotics MAiRA L is a collaborative robot designed for versatility in complex automation tasks. It features a reach of 1,600 mm and a payload capacity of 12 kg, making it suitable for applications requiring extended reach and substantial handling capability. The robot's precision is notable, with a repeatability of 0.01 mm, supporting high-accuracy operations across various industrial tasks.

Equipped with advanced artificial intelligence, including AI-based object recognition through an integrated 3D camera, the MAiRA L can autonomously handle and process objects. This capability enhances its effectiveness in dynamic environments where real-time decision-making is crucial. The robot is also built for flexibility, able to be mounted in any orientation and adapted to a range of tasks with its intuitive programming interface.

Applications for the MAiRA L include machine tending, where it efficiently manages the loading and unloading of machines, and quality assurance, where its precise control facilitates detailed inspections. Its robust design and AI integration make it a strong candidate for sophisticated prototyping tasks that demand high precision and adaptability.

FANUC CRX-25iA

Payload 25kg | Reach 1889mmThe CRX-25iA Collaborative Robot from Fanuc is an industrial robot designed for collaborative applications with humans. It has a 25 kg payload capacity and a reach of 1889 mm, making it suitable for handling heavier parts and end-of-arm tooling.

One of the key advantages of the CRX-25iA is its ease of use. The robot features a user-friendly interface that allows even those with little to no robotic experience to program it quickly and easily. The FANUC programming interface is intuitive, and users can drag and drop instructions on a tablet teach pendant to teach the robot new tasks. This feature allows manufacturers to quickly integrate the robot into their production line without having to invest significant time and resources into programming.

The CRX-25iA's safety features are also notable. The robot is designed to work safely alongside people, and its sensitive contact detection allows it to stop moving as soon as it encounters an obstacle. The robot also fully complies with ISO 10218-1 safety standards, ensuring that it is safe to use in a variety of industrial and manufacturing environments.

In addition to its ease of use and safety features, the CRX-25iA is also highly durable. It has an IP67 rating, which means it is protected against dust and liquid ingress, making it suitable for use in harsh industrial environments. This durability, combined with FANUC's world-renowned technology and proven reliability, makes the CRX-25iA an excellent choice for manufacturers looking to automate their production line.

KASSOW ROBOTS KR1205

Payload 5kg | Reach 1800mmFast and flexible industrial cobot with a reach of 1200 mm and a payload of 5 kg. Simple programming thanks to our special intuitive Kassow user interface.

ELITE ROBOTS CS66

Payload 6kg | Reach 914mmThe Elite Robots CS66 is a 6-axis collaborative robot notable for its compact design and high flexibility. With a reach of 914 mm and a payload capacity of 6 kg, it is well-suited for tasks such as material transfer, machine loading, and light assembly. The robot's compact size makes it effective in environments with limited space, while its 0.03 mm repeatability ensures precision in operations.

This robot features advanced safety functions complying with ISO 10218-1 and 13849-1 standards, including configurable safety features to adapt to various applications. Its IP65 rating indicates strong protection against dust and water ingress, suitable for diverse working environments.

The CS66's connectivity options include multiple Ethernet ports and support for various communication protocols like MODBUS TCP/RTU and EtherNet/IP. This facilitates easy integration into existing systems and remote control capabilities through a Java-based interface or a Python-based programming language.