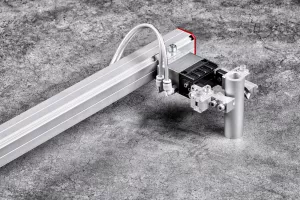

HIWIN XEG-16-C25L1-UR Specifications

Ranked Nr. 493 of 235 Grippers

| Gripper mass | 0.4 kg |

| Number of fingers |

|

| Gripper mass | kg |

| Energy source |

|

| Extra info | Stroke [both sides]:16 mm (We also have 32, 48 and 64mm stroke type) Gripping force: 25~50 N Moving speed: 1~60 mm/s Gripping speed: 1~10 mm/s Repeatability: ±0.01 mm Gripper weight: 0.4 kg Power supply: DC 24V±10% Total current: 0.5 A |