Impaqt Robotics PQ90 Specifications

Ranked Nr. 165 of 116 End of Arm Tools

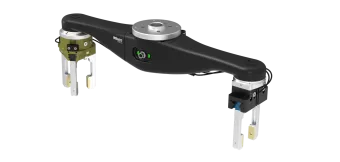

The pneumagiQ PQ90, a Red Dot 2023 Innovative Product award winner and UR+ certified device, represents a significant advancement in pneumatic EOAT interfaces for robotics. It is specifically designed to facilitate the attachment of two pneumatic EOATs at a 90° offset, optimizing the efficiency and flexibility of robotic operations. This compact unit, weighing just 580 grams, allows for a maximum payload of 5 Kg, making it an ideal solution for moderate payload collaborative robots. Its dual EOAT capability enhances the robot's functionality, enabling it to perform a wider range of tasks without the need for manual tool changes.

Featuring an IP66 rating, the pneumagiQ PQ90 is engineered to withstand harsh industrial environments, ensuring reliability and longevity in demanding conditions. It includes two sensor ports that simplify the connection and integration of sensors, reducing the complexity and clutter of wiring. Additionally, the inclusion of an air blow-off port facilitates the cleaning of workpieces or equipment, ensuring operational efficiency and the maintenance of quality standards in processes such as machine tending and spray painting applications.

Compatibility with Universal Robots through URCap and other robotic systems via Modbus RTU (RS-485) makes the PQ90 a versatile tool in the automation toolkit. This universal compatibility, coupled with the ability to use standard converters for various communication protocols, ensures that the PQ90 can be seamlessly integrated into a wide range of robotic applications. Its design focuses on enhancing operational flexibility, reducing setup times, and maximizing the utility of robotic systems in applications ranging from machine tending to light assembly and packaging.

| Type |

|

| Protection (IP) | 66 |

| Payload | 5 kg |

| Product mass | 0.58 kg |

| Energy source |

|

| Mountable grippers | 2 |

| Industry |

|

| Application |

|

| Extra info | Needs only one compressed air supply / Hose free direct connection to pneumatic grippers / Integrated air blow-off port / Built-in Silencer / Modbus RTU Communication/ Interchangeable gripper mounting / Switchable Gripper Orientation / Sensor Connectors / Status Indicators / IP66 / Quick Response TIme |