Impaqt Robotics PQ9020 Specifications

Ranked Nr. 164 of 116 End of Arm Tools

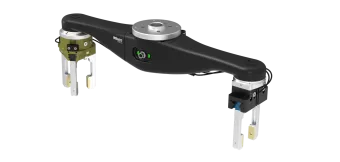

The Impaqt Robotics pneumagiQ PQ9020 stands out as a universal pneumatic End-Of-Arm Tooling (EOAT) interface that enables the mounting of two pneumatic EOATs at a 90° offset, enhancing versatility and efficiency in automated setups. Its design is specifically tailored for seamless integration with various robots, including a direct connection to Universal Robots via URCap for plug-and-play functionality, and for other robots or machinery through Modbus RTU (RS-485), supporting widespread compatibility. The PQ9020's mechanical configuration facilitates the simultaneous operation of different pneumatic tools, maximizing the utility of robotic arms in diverse applications such as machine tending, without the clutter of excessive wires or tubes.

With a payload capacity of up to 20 Kg and a compact weight of 1100 grams, the PQ9020 optimizes robot payload utilization, allowing for the handling of substantial loads without compromising the robot's operational efficiency. The unit boasts an IP66 rating, signifying its resilience in harsh environments, and includes four sensor ports that simplify the integration of sensors by eliminating the need for long wiring, further streamlining the setup. The incorporation of an air blow-off port offers additional functionality, facilitating easy cleaning of oil and burrs from workpieces, which is particularly beneficial in precision tasks.

The PQ9020 is engineered with features like built-in silencers in the exhaust port for quiet operation, and the ability to connect a single pneumatic tube to operate two tools and an air-blow-off port, which significantly reduces the complexity of the robot's pneumatic system. The interface's design considerations extend to ease of use, with tool mounting faces that accommodate different types or brands of pneumatic tools, and an inline air port for a hose-free connection, underscoring its adaptability across a range of industrial applications. This strategic combination of features positions the pneumagiQ PQ9020 as a valuable tool for enhancing the flexibility and efficiency of robotic systems in a variety of settings.

| Industry |

|

| Application |

|

| Product mass | 1.1 kg |

| Payload | 20 kg |

| Type |

|