Mitsubishi Electric RH-3CRH4018-D-S15 Alternatives & Competitors

Ranked Nr. 2 of 164 SCARA Robots

Top 10 RH-3CRH4018-D-S15 Alternatives

- Mitsubishi Electric RH-6CRH6020-D-S15

- Epson LS3-B SCARA Robot - 400mm

- Mitsubishi Electric RH-6CRH7020-D-S15

- TM Robotics TH180

- TM Robotics THL400

- Epson Synthis T3 All-in-One SCARA Robots

- Janome Servo SCARA JS3 Series

- EVS 4 Axis High Speed High Rigidity SCARA Robot EVS3-400H

- EVS 4 Axis Universal SCARA Robot EVS3-400

- DENSO LPH-040

- Turin Robotic automation SCARA STH100

Mitsubishi Electric RH-6CRH6020-D-S15

Reach 200-600 mm | Repeatability 0mm | Payload 6kgIndustrial Robot; RH-6CRH-D; 4-axis; +/- 0,02mm; 6kg; 600/200mm; incl. CR800

Epson LS3-B SCARA Robot - 400mm

Reach 400mm | Repeatability 0mm | Payload 1-3 kgPerformance, speed, payload up to 3 kg and a 400 mm reach.

Ideal for high-precision, small-parts assembly, the LS3-B SCARA Robot provides a high-performance solution with features including proprietary Residual Vibration Technology and intuitive Epson RC+® development software. Epson’s powerful servo system allows for low residual vibration, high acceleration and deceleration rates, and high-speed cycle times. Available in an ISO 4 Clean version for critical, dust-free applications, the LS3-B delivers a payload up to 3 kg and a reach of 400 mm. It also supports integrated options including parts feeding, vision, fieldbus interface solutions, RC+ 7.0 API software, teach pendants and customizable GUIs.

Residual Vibration Technology

Intuitive Epson RC+ development software

Smooth start/stop with high accel/decel rates

Fast cycle times to optimize part throughput

Up to 3 kg payload, reach of 400 mm

Mitsubishi Electric RH-6CRH7020-D-S15

Reach 200-700 mm | Repeatability 0mm | Payload 6kgIndustrial Robot; RH-6CRH-D; 4-axis; +/- 0,02mm; 6kg; 700/200mm; incl. CR800

TM Robotics TH180

Reach 180mm | Repeatability 0mm | Payload 2kgThe smallest model of our SCARA robot line, the TH180 boasts a compact body with 180mm arm span and a maximum payload of 2kg, making it ideal for use in high precision applications.

This tiny robot has the capability of handling several parts at the same time.

Product Features & Benefits:

Heavy duty arm

Rigid arm structure

Highest payload in its class

Up to 20kg payload

Arm lengths from 180 to 1200mm

Ideal for end of line packaging and assembly work

TM Robotics THL400

Reach 400mm | Repeatability 0mm | Payload 5kgTHL series SCARA robots include the THL300 and THL400 with arm lengths of 300mm and 400mm respectively.

Each THL offers a payload of 5kg. Cycle times (with 2kg load) are 48s for the THL300 and 47s for the THL400. All THL robots feature a working envelope of 4 axes, with a Z-axis rotation of 360°.

Maximum speeds range from from 5.1m/s to 6.3m/s overall.

Product Features & Benefits:

Low Cost

Light to Medium Duty

Up to 10kg Payload

Arm lengths from 300 to 1000mm

Ideal for loading and unloading applications

Epson Synthis T3 All-in-One SCARA Robots

Reach 150-400 mm | Repeatability 0mm | Payload 1-3 kgThe Ultimate Slide Alternative:

Efficient operation and seamless integration

Faster installation vs. linear-slide systems

Compact design; built-in controller

Powerful Epson RC+ programming software

400mm arm length; 3Kg max payload

Looking to automate your factory without wasting time or money on complex slide-based solutions? Now you can — with the Synthis T3 SCARA robot from Epson, the #1 SCARA robot manufacturer in the world. This innovative all-in-one offers fast, easy integration and takes less time to install than most automation solutions available. What about space constraints? The T3 virtually eliminates that issue. With a built-in controller, 110 V (or 220 V) power and integrated vision guidance, as well as other options, this space-saving robot has it all — and installs in minutes. Plus, it includes the same intuitive software and powerful features found in Epson’s high-end robots.

Janome Servo SCARA JS3 Series

Reach 350-550 mm | Repeatability 0mm | Payload 3-6 kgFeatures

Make operation settings without writing a new robot language

Dedicated Pick & Place software prepared with all the command types you need. Just choose the robot movements from the menu.

Pre-programmed software shortens setup and teaching time.

Top Class High Speed Movement and Short Standard Cycle Time

Maximum Speed: 8,300mm/sec Standard Cycle Time: 0.29sec

Enhanced high speed movement and continuous operability for increased productivity.

Cable and Tube Passage Inside the Robot Mechanism

Internal wiring and air tubing to minimize interference from peripheral devices and cables.

Expanded Pivot Axis Operating Range

The area behind the robot is accessible, eliminating wasteful extra movement and increasing robot installation flexibility.

Additional Robot Maintenance Functions

Use the robot's running data record as a guide for when to perform maintenance or replace consumable parts.

Comprehensive External Interfaces

LAN (Ethernet) port, USB memory port, 6 Field Network options, add up to 2 optional auxiliary axes.

Making Programs Is Easy

Use our original PC software or our teaching pendant.

Optional Teaching Pendant II

Our interactive input method makes direct teaching easy.

Optional "JR C-Points II" PC software

Large icons on the software screen make program creation easy.

Create, edit and save teaching data and customizing data.

We also offer a convenient point graphic editing function*.

①Programming Area

Directly input and edit program data.

②Basic Operation Area

Program just by choosing the icons you want.

③Robot Operations Area

Use the operation icons to make JOG movements.

Built-in Simple PLC Function

Handles simple communication with external devices; no need for an external PLC.

Multilingual Compatibility

Switch among 5 display languages with our PC software and 11 display languages on our teaching pendant.

EVS 4 Axis High Speed High Rigidity SCARA Robot EVS3-400H

Reach 400mm | Repeatability 0mm | Payload 1-3 kgScara robot with compact and flexible structure, fast running speed, high transmission accuracy and low noise

Robotic automation highly rigid arm design realizes high load and high speed in one package

Available in 600 to 1000mm arm span; 1kg to 20kg payload

Adapt to G3 control cabinet, provide 23 input and 23 output custom IO; support serial port, network, USB and other interface forms

Cnc robot suitable for handling, palletizing, assembly, 3C and other application fields

EVS 4 Axis Universal SCARA Robot EVS3-400

Reach 400mm | Repeatability 0mm | Payload 1-3 kgScara robot with compact and flexible structure, fast running speed, high transmission accuracy and low noise

Robotic automation highly rigid arm design realizes high load and high speed in one package

Available in 600 to 1000mm arm span; 1kg to 20kg payload

Adapt to G3 control cabinet, provide 23 input and 23 output custom IO; support serial port, network, USB and other interface forms

Cnc robot suitable for handling, palletizing, assembly, 3C and other application fields

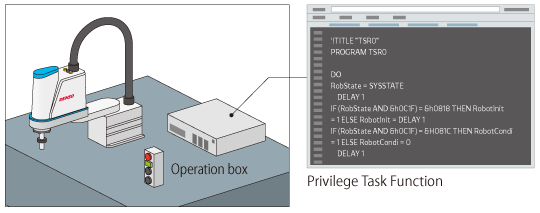

DENSO LPH-040

Reach 400-1000 mm | Repeatability 0mm | Payload 3-20 kgHigh-performance, low-priced, compact and light weight SCARA Robot!

Total arm length|400mm

Maximum payload|3kg

Position repeatability|±0.02mm

EVP2 can be built into the controller

Easy Setting of Image Processing Operations without Programming

EVP2 is an image processing application specially developed for use with a “pick & place” robot.

This software offers enhanced functionality and several times greater processing power than the previous EVP application, while maintaining the same ease of operation.

Gripper Design with High Degree of Freedom

The maximum moment of inertia of the T-axis is large in order to provide a gripper design with a high degree of freedom.

* Also supports use in other configurations including in an overhanging position.

Reduction in Work Time without the Use of PLC

The robot and surrounding equipment can be controlled together according to the purpose through use of the high-performance controller RC8 function. This feature realizes a total cost down for equipment.

Enables Control from PLC with No Programming Knowledge Required

Utilizing the command-slave function provided as a free option enables the direct control of the robot from PLC through the Function Block (FB) feature that supports 130 types of robot commands that can be openly programmed from PLC.

This feature allows adjustments to be performed with only PLC knowledge without needing to create programs on the robot side, to realize a reduction in work time for initial adjustments at the start of use.