Movu Robotics escala Specifications

Ranked Nr. 24 of 183 Mobile Robots

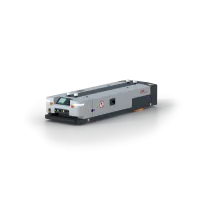

Movu Robotics' escala is a highly versatile and efficient robotic fulfillment system designed for industrial automation. It stands out for its scalability, with a low entry cost of less than $0.5 million, making it an accessible solution for businesses seeking warehouse automation. One of its key features is the ability to handle a broad range of products without the need for lifts, conveyors, or sequencers, ensuring a low total cost of ownership. Additionally, it can seamlessly integrate with existing industry-standard bins, minimizing disruptions in workflow and eliminating single points of failure.

escala's flexibility is a notable advantage, as it operates on a ramp system, allowing for rapid movement in three dimensions, saving space and maximizing speed. The system is easy to scale up by adding more ramps and robots as needed, making it ideal for businesses looking to expand quickly. It can adapt to various storage configurations, including up to 6-deep storage areas, providing access to all parts of the warehouse efficiently.

Efficiency and productivity are paramount with escala. It features state-of-the-art energy storage technology that enables on-the-fly recharging, eliminating downtime and ensuring 24/7 operational time. This boosts productivity by enabling consistent 100% performance. escala's affordability is also noteworthy, offering businesses a cost-effective initial setup and low total cost of ownership, thanks to rapid deployment and pre-built robots.

| Application |

|

| Industry |

|

| Payload | 50 kg |

| Type of Technology |

|

| Extra info | Storage containers: > 6, Charging: 24/7, Sound level: 10dB, Footprint: 50m2, Euro bin handling: >300 mm. |