OMRON Linear Axis (Cartesian) - Accurax Alternatives & Competitors

Ranked Nr. 54 of 33 Linear Motion Systems

Top 10 Linear Axis (Cartesian) - Accurax Alternatives

- YAMAHA GF type Long stroke, High payload

- YAMAHA GX10

- YAMAHA GX16

- YAMAHA B type - Timing belt drive model

- YAMAHA Basic model LBAS

- Cobotracks LMK30-S-B Linear Motion Kit for Universal Robots UR30

- YAMAHA GX20

- YAMAHA GX07

- YAMAHA GX05L

- YAMAHA Advanced model LGXS

- YAMAHA F type- High rigidity frame model

YAMAHA GF type Long stroke, High payload

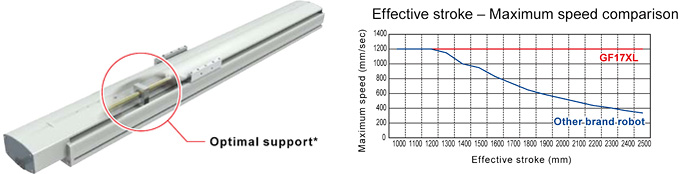

Max. Stroke 2500mmYamaha's GF type is a high-performance linear actuator that features a long stroke length of 750 to 2500mm and a maximum payload of 90kg. This linear actuator is designed to provide maximum velocity throughout the full range of stroke, without any speed deration. The actuator is capable of a maximum speed of 1200mm/sec and has a repeatability of +/- 0.01mm.

One of the key features of the GF type linear actuator is its multiple "optimal supports" that eliminate speed deration. Yamaha has implemented these optimal supports at multiple points to ensure optimal ball screw support, providing a stable and reliable linear motion. The optimal supports have been patented, showcasing Yamaha's dedication to innovation and technology.

The GF type linear actuator is suitable for various industrial applications that require high precision, speed, and a large payload capacity. For example, it can be used in the automotive industry for welding, painting, and assembly processes. It can also be used in the semiconductor industry for wafer transfer and inspection systems. The GF type linear actuator's excellent performance and reliability make it a versatile and valuable addition to any industrial automation system.

Multiple “optimal supports”* eliminate speed deration

Equipped with YAMAHA's “optimal supports”* at multiple points to ensure optimal ball screw support.

*Patent pending

4-row circular arc groove type 2-point contact guide that is resistant to large moment load is adopted.

4-row circular arc groove type 2-point contact guide with less differential slip is used for the linear guide. This guide has less ball differential slip due to its structure when compared to the 2-row Gothic arch type 4-point contact guide and maintains a satisfactory rolling movement even if a large moment load is applied or the installation surface precision is poor. The guide has characteristics that are difficult to malfunction, such as unusual wear and provides excellent reliability.

●F/N/B type

For the F type, N type, and B type, two guide frames are laid out on the high rigidity aluminum extruded material frame. Two bearing units per rail, four bearing units in total, support a large load firmly. As a large moment load is mainly converted into vertical force, the moment applied to one bearing unit becomes small to ensure excellent durability.

●F8 series

The F8 series uses a newly developed module guide to greatly reduce the crosssectional area (70 % when compared to F10). The rail is laid out in the full width of the frame to ensure the high rigidity even with compact design. Of course, this series also uses the 4-row circular arc groove type 2-point contact guide.

Note 1. Note 1. Except for T4L/T4LH and T5L/T5LH

Note 2. Except for F8 series/F10/B10.

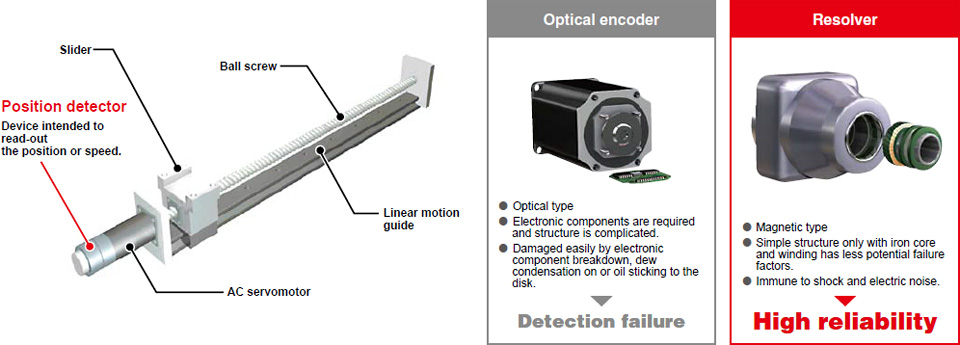

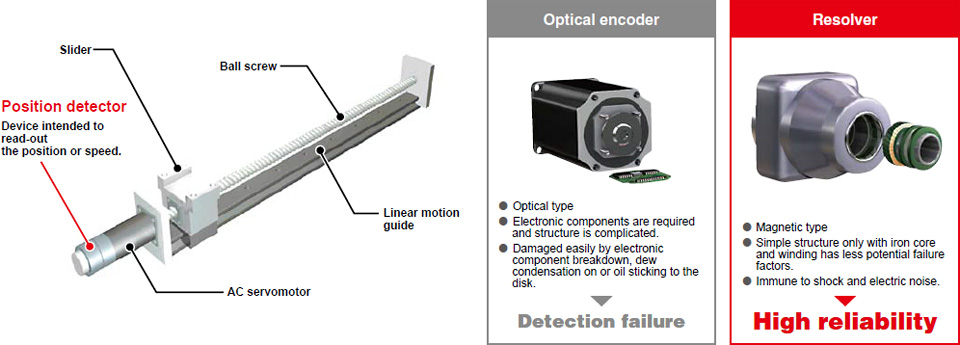

Resolver with excellent environment resistance is used for the position detector.

A resolver is used for the position detector. The resolver has a simple and rigid structure without using electronic components and optical elements. Detection problems due to electronic component breakdown, dew condensation on or oil sticking to the disk that may occur in optical encoders do not occur in the resolver. The resolver provides excellent durability. Additionally, as the absolute specifications and incremental specifications use the same mechanical specifications and common controller, desired specifications can be selected only by setting parameters. Furthermore, even when the absolute battery is consumed completely, the robot can still operate as the incremental specifications. So, even if a trouble occurs, the line stop is not needed to ensure the safe production line. Furthermore, the backup circuit has been completely renovated and now has a backup period of one year in the non-energizing state.

Long service life greatly reduces the maintenance cost.

As the acceleration is determined by the weight parameter, the service life can be assured when the weight and position of center of gravity are known.

YAMAHA's robot uses high rigidity ball screw or guide, it provides excellent durability. This greatly contributes to reduction of the customer's maintenance cost.

Controllers suitable for applications are prepared.

In addition to the robot program operation and pulse train control, a positioner that is operated by specifying a point number was added to the product lineup. Additionally, multi specifications that control multiple robots using one controller are also supported. You can select an optimal controller suitable for your application.

*Clicking an image will jump to relevant controller page.

| Programs | I/O point trace (positioner) | Pulse-train control |

|---|---|---|

|  |  |

Various custom specifications are supported.

YAMAHA supports custom orders flexibility to meet the customers' various needs.

| Addition of free slider | Free slider is added. Various applications, such as rigidity increase or use of two heads are supported. |

|---|---|

| Wide slider | To increase the slider rigidity, the standard slider is processed to the wide slider. |

| Specified stroke | A stroke smaller than the minimum stroke may be supported. For details, please consult YAMAHA. |

| Lead beyond catalog | The lead may be changed to that not stated in the catalog. For details, please consult YAMAHA. |

| Origin non-motor specifications | Even when not stated in the catalog, the origin may be changed to the non-motor side. For details, please consult YAMAHA. |

YAMAHA GX10

Max. Stroke 1250mm | Vertical Payload 30kg | Horizontal Payload 100kgYamaha's GX10 series is a linear motor stage that comes with ground ball screws as a standard feature. All models comply with JIS Standard accuracy class C5, ensuring high precision and accuracy in positioning. The GX10 series has a positioning accuracy repeatability of ±5µm, which makes it suitable for applications that require high-precision positioning.

The GX10 series has a stroke range of 100 mm to 1250 mm, which makes it suitable for various applications. The compact design of the GX10 series makes it an ideal choice for applications where space is limited. The linear motor stage is capable of handling loads up to 70 kg and can achieve maximum speeds of up to 1000 mm/s.

The GX10 series is commonly used in applications that require high-precision and high-speed positioning, such as semiconductor manufacturing, inspection equipment, and laser processing. Its high-speed capabilities make it a great choice for applications that require fast and precise movements, while its precision and accuracy make it suitable for applications that require tight tolerances.

YAMAHA GX16

Max. Stroke 1450mm | Vertical Payload 55kg | Horizontal Payload 130kgThe Yamaha GX16 is a highly versatile electric linear slide actuator designed to provide precise linear motion in various industrial applications. One of the key features of the GX16 is the ground ball screws that come as a standard feature in all models. This ensures exceptional accuracy and consistency, which is further enhanced by compliance with JIS Standard accuracy class C5. These features make the GX16 an ideal solution for applications that require high precision, such as semiconductor manufacturing equipment and inspection machines.

Another significant advantage of the GX16 is its positioning accuracy repeatability of ±5µm. This feature makes it perfect for industrial settings where precision is critical, and accuracy cannot be compromised. The stroke range of the GX16 is also impressive, ranging between 100mm to 1450mm. This gives users a wide range of options when selecting a stroke length that suits their application. With such stroke lengths, the GX16 is suitable for industrial applications that require longer strokes.

In addition to its precision and stroke range, the GX16 is also highly rigid, making it capable of handling significant offset loads without compromising performance. This feature makes the GX16 an excellent choice for applications that require high load capacity. Despite its sturdy construction, the GX16 is compact and easy to install, making it a versatile solution for various industrial settings. The combination of precision, stroke range, load capacity, and ease of installation makes the Yamaha GX16 a top-performing electric linear slide actuator for industrial applications.

YAMAHA B type - Timing belt drive model

Max. Stroke 3050mmYamaha's B type-Timing belt drive model is an advanced linear motor system that offers exceptional performance in terms of speed, stroke length, and payload capacity. One of the key features of this model is its maximum stroke length of 3050mm, which makes it ideal for applications that require long-distance transport between job processes. With a stroke length that ranges from 150mm to 3050mm, this model can cover a wide range of applications.

Another important feature of Yamaha's B type-Timing belt drive model is its maximum speed of 1875mm, which makes it one of the fastest linear motor systems available in the market. This high speed enables the system to perform tasks quickly and efficiently, which can increase productivity in manufacturing processes. Additionally, this model has a maximum payload capacity of 10 to 30kg, which means it can handle heavy loads with ease.

The B type-Timing belt drive model also comes with a 4-row circular arc groove type 2-point contact guide, which is resistant to large moment loads. This guide is designed to provide excellent reliability and durability, even in harsh environments. The 2-point contact design of the guide ensures that there is less differential slip, which means that the system can maintain a smooth and accurate movement even under heavy loads.

The 4-row circular arc groove type 2-point contact guide used in this model is also highly resistant to wear, which ensures that it can last for a long time without requiring maintenance. This guide is designed to withstand large moment loads, which makes it suitable for a wide range of applications. In addition, the guide's structure ensures that it provides a satisfactory rolling movement, even if the installation surface precision is poor.

In conclusion, Yamaha's B type-Timing belt drive model is an advanced linear motor system that offers exceptional performance, reliability, and durability. With its long stroke length, high speed, and high payload capacity, this model is suitable for a wide range of applications, including those that require long-distance transport between job processes. Additionally, its 4-row circular arc groove type 2-point contact guide provides excellent resistance to wear and large moment loads, ensuring that the system can operate smoothly and accurately for a long time.

●F/N/B type

For the F type, N type, and B type, two guide frames are laid out on the high rigidity aluminum extruded material frame. Two bearing units per rail, four bearing units in total, support a large load firmly. As a large moment load is mainly converted into vertical force, the moment applied to one bearing unit becomes small to ensure excellent durability.

●F8 series

The F8 series uses a newly developed module guide to greatly reduce the crosssectional area (70 % when compared to F10). The rail is laid out in the full width of the frame to ensure the high rigidity even with compact design. Of course, this series also uses the 4-row circular arc groove type 2-point contact guide.

Note 1. Note 1. Except for T4L/T4LH and T5L/T5LH

Note 2. Except for F8 series/F10/B10.

Resolver with excellent environment resistance is used for the position detector.

A resolver is used for the position detector. The resolver has a simple and rigid structure without using electronic components and optical elements. Detection problems due to electronic component breakdown, dew condensation on or oil sticking to the disk that may occur in optical encoders do not occur in the resolver. The resolver provides excellent durability. Additionally, as the absolute specifications and incremental specifications use the same mechanical specifications and common controller, desired specifications can be selected only by setting parameters. Furthermore, even when the absolute battery is consumed completely, the robot can still operate as the incremental specifications. So, even if a trouble occurs, the line stop is not needed to ensure the safe production line. Furthermore, the backup circuit has been completely renovated and now has a backup period of one year in the non-energizing state.

Long service life greatly reduces the maintenance cost.

As the acceleration is determined by the weight parameter, the service life can be assured when the weight and position of center of gravity are known.

YAMAHA's robot uses high rigidity ball screw or guide, it provides excellent durability. This greatly contributes to reduction of the customer's maintenance cost.

Controllers suitable for applications are prepared.

In addition to the robot program operation and pulse train control, a positioner that is operated by specifying a point number was added to the product lineup. Additionally, multi specifications that control multiple robots using one controller are also supported. You can select an optimal controller suitable for your application.

*Clicking an image will jump to relevant controller page.

| Programs | I/O point trace (positioner) | Pulse-train control |

|---|---|---|

|  |  |

Various custom specifications are supported.

YAMAHA supports custom orders flexibility to meet the customers' various needs.

| Addition of free slider | Free slider is added. Various applications, such as rigidity increase or use of two heads are supported. |

|---|---|

| Wide slider | To increase the slider rigidity, the standard slider is processed to the wide slider. |

| Specified stroke | A stroke smaller than the minimum stroke may be supported. For details, please consult YAMAHA. |

| Lead beyond catalog | The lead may be changed to that not stated in the catalog. For details, please consult YAMAHA. |

| Origin non-motor specifications | Even when not stated in the catalog, the origin may be changed to the non-motor side. For details, please consult YAMAHA. |

YAMAHA Basic model LBAS

Max. Stroke 1250mmYamaha's Basic model LBAS is a compact and versatile linear conveyor module designed to meet the needs of various automation systems. The LBAS features a newly designed integrated guide rail/frame structure that provides improved moment load capacity while maintaining a compact frame size. This innovative design ensures high rigidity and stability, making it suitable for various industrial applications.

One of the LBAS's key features is its ability to accommodate motors from most leading manufacturers, making it a highly versatile and flexible solution. The LBAS has a maximum payload capacity ranging from 2kg to 100kg, making it suitable for a wide range of applications.

The LBAS also boasts impressive speed capabilities, with a maximum speed ranging from 300 to 1,800mm/sec. This makes it an ideal choice for applications that require fast and precise linear movement. Additionally, the stroke length of the LBAS ranges from 50 to 1,250mm, providing even more flexibility in its application.

In summary, Yamaha's Basic model LBAS is a highly versatile linear conveyor module that boasts an innovative integrated guide rail/frame structure, high moment load capacity, and the ability to accommodate motors from most leading manufacturers. With a range of payload capacities, impressive speed capabilities, and a flexible stroke length, the LBAS is an excellent choice for various industrial applications.

Cobotracks LMK30-S-B Linear Motion Kit for Universal Robots UR30

Max. Stroke 7000mmThe LMK30-S-B Linear Motion Kit is specifically designed to enhance the capabilities of the Universal Robots UR30 and UR30e cobots, extending their range by up to 50 meters. With a maximum stroke of 7000 mm and a speed of 250 mm/sec, this linear track provides the flexibility and efficiency required for various industrial applications. Offering a plug & play solution, Cobotracks ensures seamless integration with the UR software, simplifying setup and operation.

Featuring a robust construction and high-performance specifications, the LMK30-S-B Linear Motion Kit offers impressive capabilities for a range of tasks. With a duty cycle of 100% and a repeatability of 0.1 mm, it ensures consistent and precise movement over extended periods of operation. With an ambient temperature range of -10°C to 60°C and an electrical input of 380V, it is suitable for operation in diverse industrial environments, contributing to enhanced productivity and reliability.

Applications for the LMK30-S-B Linear Motion Kit are varied, spanning industries such as machine loading, palletizing, and packaging. Its long stroke, high-speed capabilities, and compatibility with UR30/UR30e cobots make it an ideal solution for tasks requiring extensive reach and quick movements. Whether in manufacturing, logistics, or other sectors, the LMK30-S-B enhances the efficiency and versatility of Universal Robots cobots, enabling them to tackle a wider range of tasks with precision and reliability.

YAMAHA GX20

Max. Stroke 1450mm | Vertical Payload 65kg | Horizontal Payload 160kgYamaha's GX20 electric linear slide actuator is a high-performance solution for industrial applications that require precise linear motion. With ground ball screws as a standard feature, all models of the GX20 comply with JIS Standard accuracy class C5, ensuring exceptional accuracy and consistency. The positioning accuracy repeatability of ±5µm means that the GX20 is ideal for applications that require high precision, such as semiconductor manufacturing equipment and inspection machines.

The stroke range of the GX20 is between 100mm to 1450mm, making it suitable for a wide range of industrial applications that require a longer stroke length. Despite its impressive stroke range, the GX20 remains compact and easy to install, making it a versatile option for various industrial settings.

The ground ball screw construction ensures smooth and accurate linear motion, while the highly rigid design of the GX20 allows it to handle large loads with ease. This makes it an excellent choice for applications that require both high precision and high load capacity, such as precision assembly systems and inspection machines.

In summary, the Yamaha GX20 electric linear slide actuator is a high-performance solution for precise linear motion in industrial applications. With ground ball screws as a standard feature, JIS Standard accuracy class C5 compliance, a stroke range of 100mm to 1450mm, and exceptional load capacity, the GX20 is a versatile option for a wide range of industrial settings.

YAMAHA GX07

Max. Stroke 1100mm | Vertical Payload 16kg | Horizontal Payload 85kgThe Yamaha GX07 is a high-precision linear slide table designed for use in various industrial applications. It features ground ball screws as a standard feature, ensuring smooth and precise motion. All models of the GX07 comply with JIS Standard accuracy class C5, which guarantees high positioning accuracy and repeatability of ±5µm.

With a stroke range of 50 mm to 1100 mm, the GX07 is suitable for a wide range of applications, including semiconductor and electronic manufacturing, medical equipment, and precision assembly. It is capable of handling heavy loads and offers excellent rigidity, ensuring stable and reliable operation even under high loads and high-speed conditions.

The GX07 is also designed for easy integration with other equipment, featuring a compact and lightweight design that allows for flexible mounting options. It also offers various options for motor and controller compatibility, making it easy to customize and optimize the system to meet specific application requirements.

YAMAHA GX05L

Max. Stroke 800mm | Vertical Payload 12kg | Horizontal Payload 32kgYamaha's GX05L is a high-precision linear slide table that offers excellent accuracy and repeatability for various industrial applications. One of its key features is the use of ground ball screws as a standard feature, which ensures smooth and precise motion control with minimal friction.

All models of the GX05L comply with JIS Standard accuracy class C5, ensuring consistent and reliable performance over extended periods of use. With a positioning accuracy repeatability of ±5µm, the GX05L is capable of handling precision positioning tasks with ease, making it an ideal choice for applications that require high accuracy and repeatability.

The GX05L offers a stroke range of 50 mm to 800 mm, providing flexibility in terms of the range of motion required for different applications. Its compact design and high rigidity allow for easy installation and maintenance, while its high load capacity ensures that it can handle a wide range of payloads.

Overall, the Yamaha GX05L is an excellent choice for industrial applications that require high precision and repeatability, making it well-suited for use in industries such as semiconductor, medical, and precision manufacturing.

YAMAHA Advanced model LGXS

Max. Stroke 1450mmYamaha's Advanced model LGXS is a high-performance electric linear slide actuator that offers higher efficiency, accuracy, and reliability from its ground ball screw. The use of a ball screw in its design ensures that the LGXS provides exceptional accuracy and consistency in its movements, making it an ideal choice for applications that require high precision.

The LGXS is specifically designed to be used as a base axis of multi-axis configurations, which makes it a popular choice in the automation industry. Its maximum payload capacity ranges from 2kg to 160kg, and it can achieve maximum speeds of 300 to 2,400mm/sec. Additionally, its stroke range varies from 50 to 1,450mm, providing ample versatility for a wide range of applications.

With its advanced features and precision capabilities, the Yamaha LGXS electric linear slide actuator is well-suited for applications in the automotive, semiconductor, and electronics industries, among others. Its high efficiency and reliability make it a popular choice for manufacturing and automation applications where accuracy and consistency are paramount.