Onexia PalletizHD Specifications

Ranked Nr. 49 of 61 Turnkey Robot Solutions

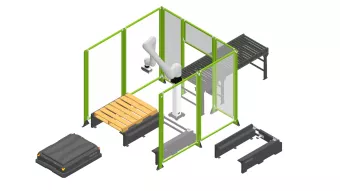

Minimal footprint, end of line packaging automation.

This is more than just a collaborative robot placing boxes on a pallet.

Why choose a PalletizHD for your packaging line?

Designed and built by a robotics integrator specializing in cobots, the "HD" is a fully automated palletizer that can easily be added to existing packaging lines.

WHAT IT MEANS TO BE "HD"

The PalletizHD is one of the most robust collaborative palletizers on market. Built on a durable and portable welded frame, the "HD" easily automates palletizing applications that are typically done by human labor.

High payload cobot - featuring a 38 lb payload, the "HD" can handle heavy cases that are difficult for humans to consistently stack.

Increased pick rate - using a custom end-effector, multiple lighter weight cases can be picked at once.

Vertical reach - the "HD" is capable of stacking pallets up to 105 inches in height by utilizing the built-in collaborative lifter.

PALLETIZING SOFTWARE

Automate palletizing without writing a line of code.

Every PalletizHD comes with our custom palletizing software preloaded on the embedded touchscreen interface.

Drag-and-drop user interface.

Custom designed by ONExia, end-users can easily add and edit pallets with no programming required!

| PalletizHD |