No reviews yet, be the first to leave a review.

Photoneo Bin Picking Studio Pricing & Product Details

Ranked Nr. 59 of 85 Robot Software

Bin Picking Studio Overview

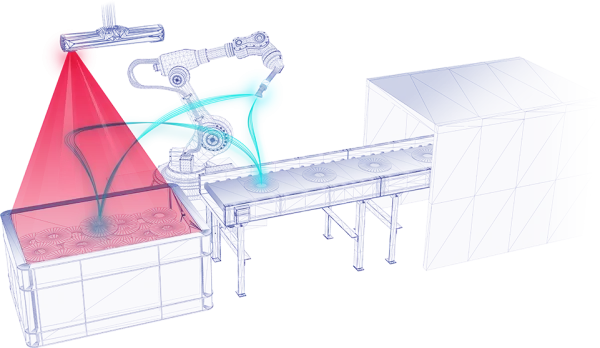

What is Bin Picking Studio?

How does it work?

- Select the robot- For you and your projects, we have developed the largest database of robots. We are supporting great amount of robot models from various brands. And if you have a robot that is not in our list - get in touch and we will gladly provide assistance and integrate it into our Bin Picking Studio.

- Upload the gripper- Upload the CAD model of your gripping tool. The model of the gripper is used for tool point configuration in the virtual environment.

- Upload your object- All you need to start planning your bin-picking gripping points is a CAD model of the product you want to pick. Upload it into the Bin Picking Studio and immediately start working with it in a virtual environment.

- Set up gripping & tool points- The setup of bin picking begins with the selection of points where and how will the gripper grasp the object. Bin Picking Studio offers you full support also in this task. Thanks to the simple visual process you no heavy math involved.

- Load your environment- In this step, we will let the Bin Picking Studio know where will the picking take place. It is done again in the easiest fashion possible - by loading a CAD model of your picking cell. Immediately after the upload, the Studio offers you a 3D visualization available for work.

- Setup your part localization-Bin Picking Studio implements a built-in engine for setting up an object localization algorithm. The algorithm based on the CAD matching approach was developed by Photoneo to suits the use for bin-picking with a focus on speed and robustness.

- Robot to camera calibration- Robot calibration was never easier. With Photoneo’s Bin Picking Studio you no longer need expensive and specific objects or specially prepared calibration sheets. One round object in the shape of a sphere is enough. Calibrate and synchronize your scanner and robot via the intuitive guided program. You will immediately receive visual feedback that you are able to validate and evaluate throughout the entire calibration.

- Interactive debugging- And finally, it is time to pick. Utilize the ultimate advance debugging tools within the virtual environment. These will allow you to see how well was the solution prepared.

What applications is Bin Picking Studio product best for?

Integrate the Bin Picking Studio to your projects instantly with these robotic brands: ABB, KUKA, YASKAWA, FANUC, Stäubli, Kawasaki, UNIVERSAL ROBOTS, MITSUBISHI ELECTRIC, NACHI, DENSO, DOOSAN

What are the specifications of Bin Picking Studio?

| Software type |

|