Photoneo Bin Picking Studio Alternatives & Competitors

Ranked Nr. 59 of 85 Robot Software

Top 10 Bin Picking Studio Alternatives

- Euclid Labs Moonflower Blue

- Delfoi ARC

Euclid Labs Moonflower Blue

Bin pickingRandom bin picking solution focused on the performances and predictability.

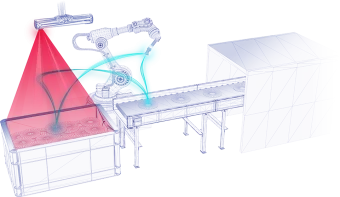

Moonflower Blue is our random bin picking solution. A bin picking process can be explained as follows: a robot (composed of six or more axis) has to pick from a box an object in a stable way to place it properly.

It generates trajectories to pick parts in a bin with a robot. Products are localized using 3D data provided by one of the supported scanners: fast and robust matching algorithms are exploited to find the 3D position and orientation of an object starting from its CAD model.

Moonflower Blue generates a picking trajectory starting from the pose of a localized product, checking for collisions between robot and surrounding environment. It can be configured to use multiple grippers and different picking strategies. In addition, when shape and distribution of products inside a bin are very complex, an automatic extraction strategy can be defined for a product model to allow the robot to take out the grasped part in a clean way.

Moonflower is focused on the performances and predictability of its solutions, as opposed to the latest year's trend in bin picking with the claim of „easy to use”.

Delfoi ARC

Offline programmingDelfoi ARC is a fast and user-friendly offline programming software for all major robot brands.

Based on selected parameters and features, the program can effectively utilise the features of the 3D CAD model and the internal WPS (Welding Procedure Specification) database of the software.

- Fast and easy: semi-automatic programming with user friendly user interface

- Multi-Robot System: supports programming of multiple synchronously co-working robots

- Jigless welding: a robot as the part positioner while another robot is welding

- High quality programs: integrated quality control and WPS (Welding Procedure Specification)

- Accurate tool paths: advanced calibration tools and trajectory management

- Generic: supports ABB, Fanuc, KUKA, Yaskawa, Motoman, Kawasaki, Panasonic, IGM, CLOOS, Reis etc.

Process features

- ‘Straight weld’ wizard

- ‘Curved weld’ wizard

- Seam searching in (1D, 2D or 3D), and auto-search

- Multi-pass welding and automatic generation of passes

- Stitch welding

- Sharp corner welding

- Copying and mirroring of welds

- Management of welding process settings and features (e.g. welding voltages, welding speeds and seam tracking)

- WPS welding parameter database

- Robot configuration management

- Tool change management

- Automated, unrestricted calculation/management of all external robot axes (e.g. gantry positioners, linear tracks and multi-axis workpiece positioners)

- Easy and fast fine adjustment of all weld paths and the robots via and moving points

- Fast validation and correction of paths

- Versatile calibration tools to ensure extreme precision in the programming of modelled cells

Advanced features

Solver Bundle is combined of advanced, automatic path planning solvers, that solve trouble-free tool paths, like weld paths, via paths and search paths. The solver bundle is included in Delfoi Auto ARC software.