REECO RB1200 Palletizer Alternatives & Competitors

Ranked Nr. 45 of 61 Turnkey Robot Solutions

Top 10 RB1200 Palletizer Alternatives

- Peeters Robot palletiser

- Peeters GoBot Palletise Solution

- Lorenscheit Automatisierungs Flex Series Palletizer

- Onexia ROBOTIC PACKAGING MACHINERY

- Onexia PalletizHD

- Indeva Cobotics PalFlex

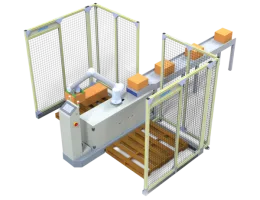

Peeters Robot palletiser

Robot Palletiser

Palletising with a robot palletiser is the automatic loading of pallets. A palletiser stacks pre-packaged items such as boxes, cans and bags onto a pallet, according to a specified pattern. We supply robot palletisers from the brands ABB, Fanuc, Yaskawa and Kuka.

Robot Palletiser stacking patterns

A palletising robot effortlessly keeps track of multiple production lines simultaneously. It’s simply a matter of creating multiple stacking patterns. Each robot palletiser is custom programmed for each client.

Take your production to the next level with our Robot palletiser!

Robot Palletiser features:

Product name: Robot palletiser

Application: Modular robot cell for industrial palletising

Capacity: up to 12 strokes per minute

Maximum stacking height: 2.5 metres

Voltage: 400 V

Cage: yes

Force sensors: no

Change over time: minimum

Maintenance: low

Vision and line tracking: optional

Energy consumption: low

Extra options:

> Malfunction data can be read out via Remote Support Router

Peeters GoBot Palletise Solution

The cobot palletiser is the palletiser robot’s little brother. The cobot also automatically loads pallets with pre-packed products but is half the size of the larger version and easy to move around. We developed this cobot palletiser, named GoBot Palletise Solution, in-house.

COBOT PALLETISER IDEAL FOR SMES

Our GoBot Palletise Solution is the ideal (and often first) robot solution for small and medium-sized industrial companies that no longer want to manually stack goods coming off of the production line.

THE COBOT IS EASY TO HANDLE

(Pre)programming makes it easy for any employee to work with this cobot. No programming knowledge is required to set stacking patterns, for example. The cobot palletiser also stores each stacking pattern in its memory.

The cobot is equipped with motion sensors so people can work safely in its vicinity (changing pallets, for example, is not a problem)

Cobot Palletiser features:

- Product name:

- Application: Standard turnkey palletising cobot for light industrial palletising

- Capacity: up to 6 strokes per minute

- Maximum stacking height: 2 metres

- Voltage: 230 V

- Dimension: < 4 m2

- Cage: no

- Installation time: 1 day

- Force sensors: yes

- Change over time: minimum

- Maintenance: low

- Vision and line tracking: optional

- Energy consumption: low

- Delivery time: 4-6 weeks

- Programmed according to the ISO/TS-15066 standard

- Extra options:

> Malfunction data can be read out via Remote Support Router

> Lift unit for stacking up to 2 metres

Lorenscheit Automatisierungs Flex Series Palletizer

The Flex Series Palletizer from Lorenscheit Automation Technology is an all-in-one palletizing solution combining a cobot, a vacuum gripper and Lorenscheit’s proprietary software. This complete solution allows you to easily automate your end-of-line packing. With the Universal Robots UR10e and an additional vertical axis, packages weighing up to 7.5 kg can be palletized to heights up to 2.20 m.

Onexia ROBOTIC PACKAGING MACHINERY

Automate the dull and ergonomically unsafe tasks associated with end-of-line packaging operations. Our robotic packaging solutions are turn-key and designed to fit into both new and existing operations.

Turn-key Automation

Robotic solutions for every step in the packaging process! Featuring a modular design, all of our solutions can be added to both new and existing lines.

Fully automated packaging lines

Robotic case erectors & case packers

Collaborative robotic palletizers

Quality control vision integration

Custom conveyor configurations

COLLABORATIVE PACKAGING ROBOTS

By integrating collaborative robots into our packaging systems, we can provide solutions that are modular and easily added to both new and existing packaging lines.

Case Erector & Case Packers

Automate an existing line within the same footprint! By using cobots, case erectors and case packers are easily integrated into existing lines.

SYSTEM FEATURES

Multiple flat shipper magazines

Top and bottom taper options

Custom end-of-arm tooling

No caging or guarding needed to operate

Onexia PalletizHD

Minimal footprint, end of line packaging automation.

This is more than just a collaborative robot placing boxes on a pallet.

Why choose a PalletizHD for your packaging line?

Designed and built by a robotics integrator specializing in cobots, the "HD" is a fully automated palletizer that can easily be added to existing packaging lines.

WHAT IT MEANS TO BE "HD"

The PalletizHD is one of the most robust collaborative palletizers on market. Built on a durable and portable welded frame, the "HD" easily automates palletizing applications that are typically done by human labor.

High payload cobot - featuring a 38 lb payload, the "HD" can handle heavy cases that are difficult for humans to consistently stack.

Increased pick rate - using a custom end-effector, multiple lighter weight cases can be picked at once.

Vertical reach - the "HD" is capable of stacking pallets up to 105 inches in height by utilizing the built-in collaborative lifter.

PALLETIZING SOFTWARE

Automate palletizing without writing a line of code.

Every PalletizHD comes with our custom palletizing software preloaded on the embedded touchscreen interface.

Drag-and-drop user interface.

Custom designed by ONExia, end-users can easily add and edit pallets with no programming required!

Indeva Cobotics PalFlex

Modular and ready-to-use solution for any palletizing need of boxes, cans or other objects up to 16 kg (after checking the applied tool).

Speed up to 14 pieces/min (guaranteed rate with box weight of max 8 kg and with non-collaborative working mode and multiple gripping head).

The large color panel mounted on the machine assists the user in a clear and fast way, allowing him to optimize the palletizing process automatically without the need of additional programs.

Possibility of managing interlayers, thanks to the special warehouse module and the creation of particularly high pallets by means of a telescopic column.

PalFlex advantages:

- Easily transportable with a simple pallet truck

- Motorized telescopic column for Cobot to reach different heights

- Plug & Play: just a standard 220V and AC outlet to get started

- Ballasted base, possibility of working without having to anchor it to the floor and flexibility in positioning

- Secure: Immediate lockout upon obstacle detection, safety level Cat.3 PL d, guaranteed by the CE marking in accordance with the Machinery Directive 2006/42/EC

- Versatile: gripping hand can be customized according to the customer’s specific needs. Realizable in different shapes depending on what is to be handled (16-20 kg after verification of the cobot payload)

- Quick and easy task configuration using dedicated palletizing software, with just a few steps, allows the creation and optimization of palletizing configurations