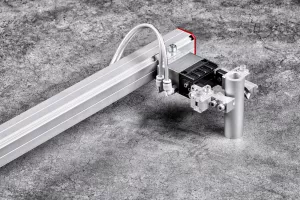

Robotiq 3-Finger Specifications

Ranked Nr. 62 of 235 Grippers

The Robotiq 3-Finger adaptive gripper is an ideal option for maximum versatility and flexibility: picks up any object of any shape. Adapts to the object’s shape for a solid grip, so you can focus on the task and not the grasping. With force, position and speed control for each individual and 4 different grip modes, the Robotiq 3-Finger gripper can pick almost anything.

| Max. Force | 70 N |

| Payload | 10 kg |

| Max. Stroke | 155 mm |

| Min. Force | 30 N |

| Gripper mass | 2.3 kg |

| Operation type |

|

| Energy source |

|

| Gripper mass | kg |

| Max. Force (N) | 70 |

| Min. Force (N) | 30 |

| Max. Stroke (mm) | 155 |

| Number of fingers |

|

3-Finger Downloads

Product sheet 3 F EN

You need to

register

to download this file.