SOLOMON vision AccuPick 3D Specifications

Ranked Nr. 12 of 85 Robot Software

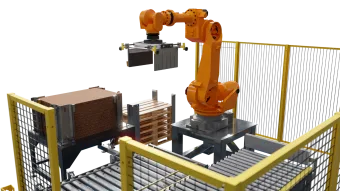

SOLOMON Vision AccuPick 3D utilizes AI-driven 3D machine vision to handle complex material handling tasks with high precision. It generates detailed point clouds to detect and manipulate random or unknown objects, regardless of their appearance, orientation, or spatial location. This technology is particularly effective in overcoming limitations associated with traditional vision systems, including issues with transparent, reflective, or irregularly shaped objects.

AccuPick 3D features advanced collision-free motion planning and a user-friendly graphic-based interface, which enhances its ability to execute complex pick-and-place tasks efficiently. Its compatibility with open platforms and auto-labeling capabilities streamline integration into various systems, eliminating the need for CAD files. This system is designed to handle soft, deformable, small, or overlapping objects with ease, making it suitable for diverse manufacturing and retail automation environments.

The system's key advantages include its ability to handle challenging conditions, such as transparent or reflective objects and complex backgrounds. By leveraging industry-leading AI and 3D vision technologies, AccuPick 3D provides a versatile and effective solution for automated bin picking and material handling.

| Software type |

|