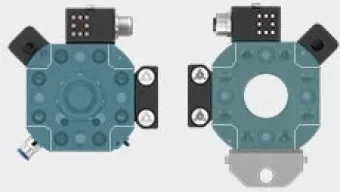

STÄUBLI MPS 080, 130, 260 Specifications

Ranked Nr. 82 of 116 End of Arm Tools

Robotic tool changing systems from the MPS product line are impressive due to their multifunctional technology applications and cover the entire bandwidth of customer-specific applications.

The MPS 080 - 260 is an extremely flexible solution for medium payloads. This automatic, very compact tool changer offers numerous module variations for various components within media, data and energy transmission, such as pneumatics, vacuum and cooling, signal and power supply and primary current.

Choose your model:

MPS 015, 025, 035, 055

Payload 10-55 kg

MPS 631,1530, 2531

Payload 630-2500 kg

MPS 080, 130, 260

Payload 80-350 kg

| Payload | 80-350 kg |

| Repeatability (mm) | 0.01 mm |

| Extra info | Transmission Modules: Electrical modules for signal and servo power transmission / Transfer modules for fluid, pneumatic and vacuum connectors / Primary circuit modules for welding power transmission / Integrated IDA bus module for condition monitoring / Ground pin modules for shielding and earth connection / Active Docking safety modules Performance Level d, Category 3 / |