Zimmer SERIES GED5000 Specifications

Ranked Nr. 226 of 235 Grippers

- Approximately the same gripping force as a comparable pneumatic gripper

- Self-locking mechanism in case of power drop

- Same connection hole patterns as a comparable pneumatic gripper

- Plug and play – single-cable solution, supports incredibly easy control using I/O signals or IO-Link

- Integrated ACM control module - option of configuring gripping force, travel time and switching points

- Protected from corrosion and sealed in accordance with IP64

- Brushless DC motor – up to 30 million cycles without maintenance

Choose your model:

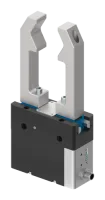

SERIES GPD5000

Parallel

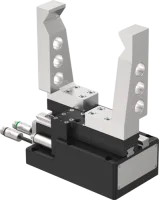

SERIES MGD800

SERIES GD300

SERIES GD

SERIES GPD5000IL

Parallel

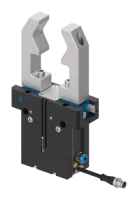

SERIES GED5000

Parallel

SERIES GED6000IL

HRC-07 Collaborative

Angular

| Number of fingers |

|

| Operation type |

|

| Energy source |

|

| Max. Stroke (mm) | 60 |

| Protection (IP) | 54 |

| Gripper mass | kg |

| Extra info | Stroke per jaw: 6[mm]- 10[mm] / Gripping force: 960[N]- 1520[N] / Weight: 1.09kg- 2.33kg / IP class: IP64 |