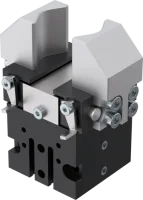

Zimmer SERIES MGD800 Specifications

Ranked Nr. 226 of 235 Grippers

- Gripper jaws may be almost 100% longer in comparison to the benchmark

The highest force and torque measurement enables flexible for maximum dynamics - Best price/performance ratio

Reduces your investment costs and speeds the ROI for your application - Failure-free continuous operation

Our uncompromising "Made in Germany" quality guarantees up to 10 million maintenance-free cycles

Choose your model:

SERIES GPD5000

Parallel

SERIES MGD800

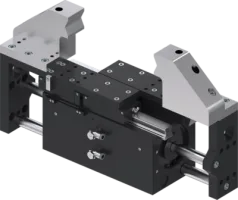

SERIES GD300

SERIES GD

SERIES GPD5000IL

Parallel

SERIES GED5000

Parallel

SERIES GED6000IL

HRC-07 Collaborative

Angular

| Number of fingers |

|

| Extra info | Stroke per jaw: 1[mm]- 12[mm] / Gripping force in closing: 30[N]- 1420[N] / Gripping force in opening: 34[N]- 1200[N] |