Are you considering upgrading your manufacturing line? Cobot palletizing could be your solution. These robots are tailored for businesses like yours, looking to enhance efficiency while keeping costs down. In this guide, we’ll uncover five key benefits of adopting cobot palletizing. You’ll learn how these robots boost flexibility, ensure safety, and keep your costs in check.

By the end of this article, you’ll understand how cobots can streamline your operations and why they might be the smart choice for your production needs. Let’s get started on transforming your palletizing process!

What is a Cobot Palletizer?

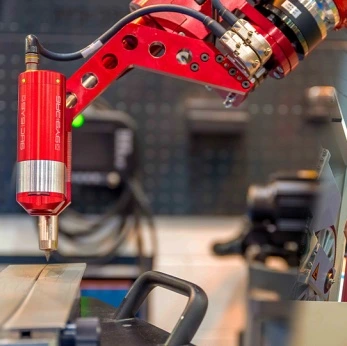

A cobot palletizer is a robotic helper specifically designed to assist with stacking boxes on pallets at your workplace. It’s built to work alongside your team, ensuring tasks are done safely and efficiently. With its smart sensors, the cobot adjusts to different box sizes and weights, making it incredibly adaptable to your needs. It’s also compact, so it fits right into your current setup without taking up much space. If you’re looking to speed up your packing process without a big overhaul, a cobot palletizer could be the perfect addition.

Want to see how a cobot palletizer can transform your production line? Explore our complete guide on the best solutions for stacking boxes in 2024.

Say Goodbye to Coding Headaches with Cobots!

Programming cobots is a breeze with three simple methods, and you don’t need to be a coding expert. You can manually guide the cobot’s arm to where you want it to go, and it will remember the movements for future tasks. This makes programming with cobots easy and stress-free.

No more dealing with complicated coding. The ‘drag and drop’ method allows you to easily move the cobot to your desired locations. It remembers the path and stops, making your work smooth and efficient.

The third and easiest way to program your cobot is with the ‘plug and play’ option. You can choose your pallet pattern from a user-friendly interface, even if you’ve never programmed a teach pendant before. Cobots are designed to be operator-friendly, making tasks easy for everyone.

5 Advantages of Cobot Palletizing:

1. Enhanced Flexibility:

Easily Adapt Your Setup:

Cobots are game changers when it comes to fitting into your current setup. You don’t need to overhaul your production area. Instead, the same cobot can handle different products—big or small—making it super flexible for whatever you’re packing today or tomorrow.

Quick Changes for New Tasks:

Need to switch tasks on the fly? No problem. Reprogramming your cobot is straightforward. If you’re rolling out a new product or need to adapt to a sudden change in order, your cobot can switch gears quickly. This means less downtime for you and a production line that keeps pace with market demands and seasonal shifts.

2. Improved Safety:

Built-in Safety Features:

Your cobot has safety sensors that are always on guard. If something gets in its way, it stops immediately—no bumps, no bruises. This ensures that your workspace is safer, helping prevent accidents before they happen.

Keeping Your Team Healthy:

With cobots doing the heavy lifting, your team won’t have to. This reduces the wear and tear on their bodies from repetitive tasks and heavy lifting, cutting down on injuries like back pain or muscle strains. Plus, less physical fatigue means your employees stay sharper and safer throughout their shifts.

3. Cost Efficiency:

Affordable Startup Costs:

Cobot palletizers are surprisingly affordable. Prices start around $24,000 and can go up to $50,000, based on the features you need. This is much cheaper than traditional robots, making cobots a great choice if you’re looking to automate on a budget. Plus, setting them up is straightforward—they integrate smoothly with your existing systems, saving you even more money on installation.

Save on Labor and Reduce Injuries:

Imagine cutting down on your labor costs dramatically. Cobots work non-stop—day and night—without needing breaks. This means you can keep your production line moving faster without extra hands. Also, cobots take over the heavy lifting and repetitive tasks, greatly reducing the chance of injuries at work. Fewer injuries mean fewer medical bills and compensation costs, keeping more money in your pocket.

Boost Your Output Without the Extra Costs:

Cobots don’t just work hard; they work smart. They use less electricity and need minimal maintenance, maybe just a few hundred dollars a year. This keeps their running costs low. By keeping production going 24/7, cobots ensure you’re always meeting demand, helping you make the most out of your investment in no time—often within a year or two

4. Increased Productivity:

Non-Stop Precision:

Your cobots work tirelessly—day in, day out, without taking a break. They deliver consistent accuracy around the clock, ensuring every pallet is perfectly stacked. This relentless operation not only speeds up your production but also cuts down on errors and waste. You can count on your cobots to keep things running smoothly, which means you can focus on other key aspects of your business without worrying about downtime or mistakes.

Boosting Team Morale and Efficiency:

When cobots handle the repetitive lifting and moving, your team can shift their attention to more engaging and thoughtful tasks. This change can make a big difference in how they feel about their work. Happier employees tend to be more creative and productive, leading to better job performance and potentially sparking new ideas for improving your processes. By letting cobots do the grunt work, you’re not just easing the physical load for your team—you’re also giving them a chance to shine in roles that require more skill and creativity.

5. Scalability & Future-Proofing:

Grow With Your Needs:

Your cobots are ready to grow with your business. As your demands change—maybe you’re handling more orders or introducing new products—your cobots can easily adjust. They’re designed to be reprogrammed quickly and moved wherever they’re needed most. This flexibility means you won’t have to buy new equipment every time your business goals evolve.

Stay Ahead with Updates:

Investing in cobot palletizing means you’re set for the future. Cobots get better over time, thanks to software updates that bring new features and improvements. This keeps your setup on the cutting edge, ensuring you maintain a lead in a competitive market. With cobots, you’re not just keeping up; you’re staying ahead, ready to adapt to whatever the future brings.

Conclusion:

Choosing cobot palletizing is a smart move for your production line. These robots not only handle tasks round the clock but also grow with your business, adapting quickly to changes. By integrating cobots, you’re setting up your operations to be safer, more efficient, and ready for future challenges. Interested in taking your production to the next level? Dive deeper into cobot solutions and discover how they can revolutionize your operations, making your workplace more dynamic and forward-thinking.

The information you shared in the blog is very much useful.

I like the helpful information you provide in your articles. I will bookmark your blog and check again here regularly. I am quite certain I will learn lots of new stuff right here! Best of luck for the next!