Choosing the right CNC (Computer Numerical Control) machine can be a crucial decision for your work. CNC machines are like computer-controlled helpers that use tools to make things from materials such as metal and wood. In this article, we will guide you step by step on how to select the best CNC machine for your specific needs.

But before we begin,

What is a CNC Machine?

A CNC machine is a smart tool that follows computer instructions to do tasks with great accuracy. It can cut, shape, and make things exactly as planned. Unlike older machines operated by people, CNC machines work by themselves, making manufacturing more efficient and error-free.

So, let’s explore how to choose a CNC machine.

Understanding Your Needs:

1. Know Your Materials:

Before you decide on a CNC machine, it’s essential to think about the materials you’ll be working with. Different machines are designed for different materials. Some are great for handling metal, while others excel at working with wood.

2. Decide on the Size:

Consider the size of the items you want to create. If your projects involve making large objects, then you’ll need a larger machine. On the other hand, if you’re mainly interested in crafting smaller items, a smaller machine may be more suitable for you.

3. Think About Complexity:

Think about how complex your designs are. If your projects require intricate details, look for a CNC machine that can work with precision and handle intricate designs.

Types of CNC Machines:

Now, let’s explore the various types of CNC machines available to help you decide which one suits your needs best:

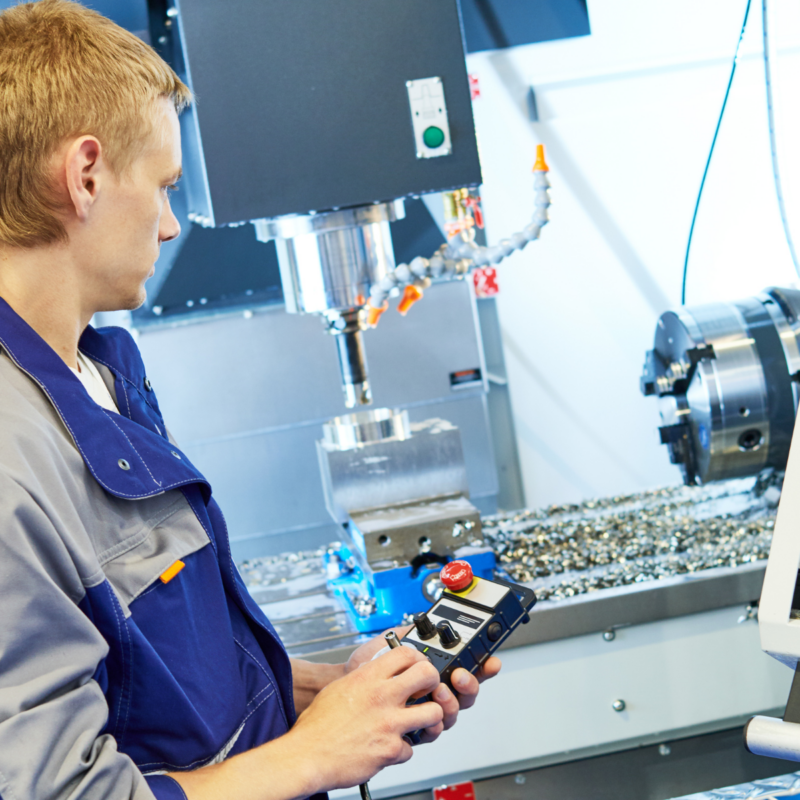

1. CNC Mills:

CNC mills are quite common and versatile. They can cut and shape materials in many different ways, making them suitable for a wide range of tasks. Whether you need to create prototypes or intricate parts, CNC mills can be a valuable asset.

2. CNC Lathes:

CNC lathes are specialized for crafting round objects, such as machine parts. They work by spinning the material while cutting it, making them ideal for projects that involve cylindrical shapes.

3. CNC Routers:

CNC routers are primarily used for cutting wood and plastic. They are excellent for crafting items like signs and other objects made from these materials. If your work primarily involves wood and plastic, a CNC router may be the right choice.

4. CNC Plasma Cutters:

CNC plasma cutters use hot plasma to cut through metal quickly and efficiently. They are especially useful for tasks that involve cutting thick metal. If metalworking is your focus, a CNC plasma cutter might be the perfect fit.

To learn more about the different types of CNC Machines on the market.

3 Budget Considerations:

1. Initial Cost:

CNC machines can be a significant investment, so it’s crucial to determine your budget before starting your search. Knowing your budget will help narrow down your options and prevent you from overspending.

2. Maintenance Costs:

Keep in mind that all machines require maintenance. However, the level of maintenance and associated costs can vary from one CNC machine to another. Be prepared for potential maintenance expenses when planning your budget.

3 Training Costs:

Using a CNC machine can be challenging, especially if you’re new to it. You may need to budget for training to acquire the necessary skills and knowledge to operate the machine effectively.

4 Important Features:

As you search for the right CNC machine, consider the following important features:

1. Power & Speed:

Think about how fast and powerful you need the machine to be. Machines with more power and speed can complete tasks more quickly, but they may come with a higher price tag. Carefully weigh your needs against your budget.

2. Size and Space:

Evaluate the available space in your workspace to ensure that the chosen CNC machine can fit comfortably. It’s essential to have enough room for both the machine and your work materials.

3. Software Check:

Whether the CNC machine comes with user-friendly software. Easy-to-understand software will make it simpler for you to control and program the machine effectively.

4. Support & Warranty:

Research the warranty offered with the machine and the availability of customer support. A good warranty and responsive customer support can be invaluable if you encounter any issues or need assistance.

Try Before You Buy:

If possible, consider trying out the CNC machine before making your final decision. This hands-on experience can give you a better understanding of how the machine operates and whether it meets your specific needs and preferences. Some sellers may even offer the opportunity to test the machine before making a purchase.

Conclusion:

Choosing the right CNC machine is a significant decision that can impact your work greatly. To make an informed choice, take the time to think about the materials you’ll be working with, the size and complexity of your projects, and the associated costs. Pay close attention to crucial features like power, size, software usability, and available support. Whenever feasible, test the machine before making your purchase. Armed with this knowledge and careful consideration, you can confidently identify the ideal CNC machine for your specific needs.

Do You Need To Compare Different CNC Machines?

Hi there, I just came across your blog through Google and found it really informative. I’m going to keep an eye out for more updates. I’d appreciate it if you continue sharing such content in the future. A lot of people will benefit from your writing. Cheers!