Industrial robots are a big help in lots of industries. Among them, articulated robots are the most important ones. They do great work and help with manufacturing.

In this article, we’ll talk about articulated robots, why they matter in industries, and how their importance is on the rise.

What is an Articulated Robot?

An articulated robot has multiple joints that move in different directions. These joints let the robot handle many tasks, just like your arm.

You can use articulated robots in various industries because they are flexible. They come with advanced sensors and precise controls. This technology helps them do complex and repetitive jobs accurately.

In your business, these robots can boost efficiency and precision, especially in manufacturing, automotive, and electronics industries. Using an articulated robot can help you stay competitive in today’s fast-changing world.

What’s the Difference Between an Industrial Robot and an Industrial Articulated Robot?

Industrial Robots:

Industrial robots are machines used for tasks like welding, assembly, and packaging. Types include Cartesian, SCARA, and delta robots, each designed for specific tasks in your operations.

Industrial Articulated Robots:

Articulated robots are a type of industrial robot with multiple joints. These joints allow them to move in various directions, making them ideal for complex tasks like assembly and material handling. You might use them in industries such as automotive and electronics.

Key Difference:

The key difference is flexibility. Articulated robots have more joints, which lets them move in a wider range compared to other types of industrial robots. This flexibility helps them perform tasks that require precise and varied movements.

Need Free Advice For Your Robot Project?

How Does Industrial Articulated Robots Work?

Industrial articulated robots use mechanical parts, sensors, and smart control systems. They follow instructions to do tasks accurately. Here’s a simple explanation of how they work:

1. Giving Instructions:

Skilled operators or engineers use special software to tell the robot what to do. They say how fast it should move and provide all the details needed to finish the job.

2. Gathering Information:

These robots have sensors, like force sensors and vision systems, to find out what’s around them. These sensors help the robot see objects, measure distances, and adjust its movements.

3. Planning the Moves:

Once the robot knows what to do, its control system figures out how each part should move. It calculates the angles and positions to guide the robot from one place to another, making sure it avoids obstacles.

4. Turning On:

The robot’s joints are powered by strong electric motors or hydraulic systems, depending on how it’s built. These motors give the force needed to move the robot’s arm and tool correctly.

5. Doing the Job:

The robot follows the steps it was told and keeps an eye on its sensors. It changes its position, speed, and force based on what it senses in real-time.

6. Using the Tool:

This means doing things like grabbing, welding, painting, or whatever the task requires.

7. Staying Safe:

These robots come with safety measures, such as emergency stop buttons, barriers, and safety sensors. These are in place to keep human operators safe and avoid accidents.

By sticking to these steps, industrial articulated robots can do lots of jobs with accuracy. They are great at tricky movements and can handle different tasks, which is why they are really important in today’s industry.

Common Applications:

Articulated robots are super versatile and can do lots of different jobs in various industries. Here are some examples:

1. Assembly:

These robots often work on assembly lines, putting things together, welding, and checking products for quality. They work fast and don’t make many mistakes, which helps factories do more and better work.

2. Moving Objects:

In warehouses and factories, articulated robots are great at moving things around. They can sort, stack, and pack items, making the whole process of moving things much easier.

3. Painting & Coating:

Some of these robots have special tools for painting and coating jobs. They do this very carefully, especially in industries like making cars where getting the paint just right is super important.

4. Picking & Placing:

These robots are also really good at picking up things and putting them down in different places. They can load and unload stuff from conveyor belts or organize products on shelves, making these jobs automatic and simple.

4 Benefits of Using an Articulated Robot:

Articulated robots offer several clear benefits that can enhance your operations. Here’s how they can help:

Improved Precision:

These robots give you precise control, reducing mistakes and improving the quality of tasks like assembly, painting, and welding.

Increased Productivity:

They work without breaks, handling repetitive tasks faster and boosting your production speed.

Enhanced Flexibility:

You can reprogram them for different tasks, making it easy to adjust to changing production needs in your business.

Better Safety:

Their built-in sensors allow them to make real-time adjustments, keeping your operations safer.

For more detailed insights, read the full article here: Benefits of Industrial Robots.

Market Outlook:

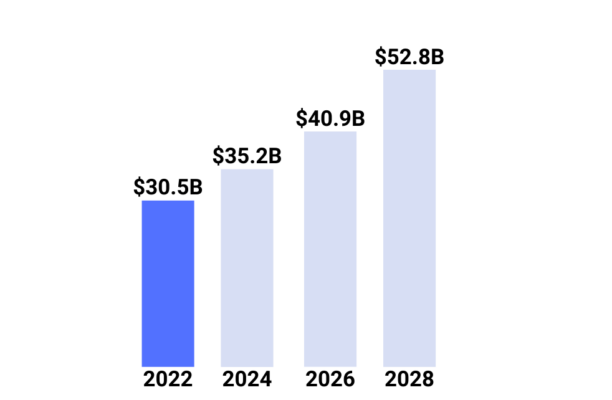

Articulated robots are getting more important in different industries. In 2021, they were worth $27.3 billion, and in 2022, it’s expected to be $30.5 billion. According to Statista, the market is predicted to reach $35.2 billion in 2024 and around $40.9 billion in 2026, possibly reaching nearly $52.8 billion by 2028.

This growth shows that more industries are using articulated robots for tasks like assembling, moving, painting, and handling things. As we look ahead to 2030 and beyond, articulated robots will keep growing as automation becomes more common worldwide.

Predicted Market Growth

Predicted Market Growth

Future of Articulated Robots:

As technology gets better, articulated robots will become even more important. Here are some exciting things we can expect:

1. Better Senses & Vision:

New sensors and vision systems will help articulated robots see better. This will make them better at working in tricky places and working well with people.

2. Using Artificial Intelligence & Learning:

Articulated robots will get smarter by using artificial intelligence and learning from machines. This will help them make better decisions and handle tough situations. This means they will get better at doing hard tasks.

3. Working with People:

In the future, articulated robots will work more closely with humans. They will be safer and easier to program, which will help people do their jobs better and be more productive.

Conclusion:

Articulated robots are important for improving your operations. With multiple joints, they can handle tasks like assembly, moving materials, and painting with precision. You can use them in industries like manufacturing, automotive, and electronics to increase efficiency. These robots follow specific instructions and use sensors to adjust in real time, ensuring accuracy and safety. In the future, they’ll get smarter with AI, better vision systems, and more ability to work closely with humans. This will make them even more valuable for automating your processes and staying competitive.