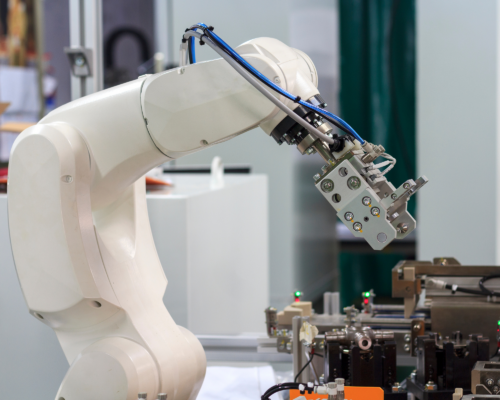

Cobots need grippers on their arms to grab and move things. Grippers come in different types, like air-powered, electric, vacuum, and magnetic ones. Each type has its own strengths and weaknesses, and the choice depends on what you need to do.

Understanding these gripper options is crucial. Grippers can handle different tasks and objects, but they also have limits. Some are great for small, delicate things, while others work well with big, heavy stuff.

Consider where the robot will work, the cost, maintenance, and the expertise required. But first, let’s talk about the main types of cobot grippers.

10 Types of Cobot Grippers:

In industries, there are various cobot grippers, each made for specific jobs and having special strengths. This variety lets users pick the right gripper for their needs, making smart choices based on what they want. Some top cobot gripper types are pneumatic, electric, vacuum, and hydraulic grippers.

Now, let’s dive into these different types of cobot grippers:

1. Hydraulic Grippers:

Hydraulic grippers use pressurized oil to grab things with strong force. A pump sends the oil to parts inside the gripper, making it open and close with a lot of power. These grippers are awesome for heavy jobs like metalwork, building, and moving stuff because they’re super strong for their size.

But there are a few things to consider. Hydraulic grippers are usually bigger and heavier than other types. They also need more upkeep to work well over time, unlike some other grippers.

2. Vacuum Grippers:

Vacuum grippers are unique tools that use suction to grab and move things. They work by making a strong sucking force in their cups or pads, which holds the object really well.

People often choose these grippers for fragile, odd-shaped stuff, or when they need super-precise work. They’re also great for things with holes or a smooth surface that regular grippers can’t handle.

Usually, vacuum grippers use an outside suction pump, and the robot has a vacuum controller to control them.

An example of a vacuum gripper is AGS’s Vacuum Pads.

3. Pneumatic Grippers:

Pneumatic grippers, which are one type of cobot gripper, work with air pressure to move their fingers. They are usually crafted from aluminum or steel and feature a simple, compact design. These grippers are good for tasks with light stuff and not too much gripping force.

Pneumatic grippers have some benefits, like being fast, accurate, and not too expensive. They’re also easy to put in and take care of. But they’re not the best for heavy things, and they might not be as precise as some other grippers.

4. Servo-Electric Grippers:

A servo-electric gripper, also called an electric gripper or electric actuator gripper, uses electric motors and servo drives to control its fingers. This helps it open and close very accurately. These grippers are famous for their accuracy and cooperate effectively with other automation gear.

You can program servo-electric grippers to do things like picking up and putting down stuff or sorting parts. They’re great for tasks with heavy things and strong gripping. They’re really good at being accurate and fast, and they can handle heavy stuff. But they might be a bit expensive to buy and take care of.

5. Angular /Parallel Grippers:

Angular grippers, also known as parallel grippers, are a type of robotic gripper that are designed to grip an object at a fixed angle. They are typically used to grip objects that have a symmetrical shape and require a specific orientation for proper handling.

This type of gripper use two parallel jaws to grip an object, and the jaws move in opposite directions to open and close the gripper. They are often used in manufacturing and assembly applications, such as pick and place, packaging, and material handling. They can be pneumatic, hydraulic or electric and the payload capacity of angular gripper can vary depending on the manufacturer.

6. Soft Grippers:

Soft grippers are a special type of robot gripper designed for gentle handling. These grippers are typically crafted from bendable materials such as silicone, rubber, or soft plastics. These grippers find use in various tasks such as working with food, electronics, or assembling medical devices.

Manufacturers create soft grippers to match the shape of the objects they hold perfectly. This design ensures a secure and effective grip, making them valuable in a wide range of applications. They are suitable for situations where regular grippers might be too rigid or could damage the object. You can control them using air or electricity, and their holding capacity varies depending on the manufacturer. They are useful in many industries, such as delicately handling food in the food industry or working with sensitive electronic components in factories.

7. Magnetic Grippers:

A magnetic gripper is a tool that uses magnets to hold and move metal things. It has strong magnets that stick to materials like iron and nickel. These grippers are often used in jobs like moving metal parts in manufacturing or packing materials. They help handle metal objects easily and dependably in various workplaces.

8. Adaptive Grippers:

An adaptive gripper can change its shape or size to fit different objects. This means it can handle various items without needing manual adjustments or different specialized grippers.

Industries like manufacturing, assembly, and packaging benefit from adaptive grippers, making robotic systems more flexible and efficient. They allow automation of tasks that used to be hard or impossible.

9. Jamming Grippers:

A jamming gripper, also called a “jamming finger,” uses a flexible material like foam or sand. This material becomes hard when you blow air into it, allowing the gripper to shape itself around an object and hold it securely.

Jamming grippers are great because they’re light, cost-effective, and can handle all sorts of objects with different shapes and sizes. They’re useful in industries like manufacturing, assembly, packaging, and shipping, where you work with various items.

10. Mechanical Grippers:

A mechanical gripper is a device that uses mechanical means, like jaws or fingers, to grab and hold things. You often see them in industrial robots and automation systems, where they handle and move objects during manufacturing or assembly.

You can customize these devices to match different types of objects and working conditions. Whether you’re dealing with delicate items, large heavy objects, or a clean environment, you can adjust the grippers to the task. They use different methods, like air, water, or electric power, to do their job well.

Advice:

When you’re checking the risk assessment of a cobot gripper, there are some important things to think about:

1. Safety Standards: Make sure the gripper follows safety rules like ISO 10218-1 and ISO/TS 15066. These rules talk about cobots and keeping them safe.

2. Risk of Crushing: Look at the risk of the gripper’s jaws crushing or pinching something between them and other robot parts or stuff around it.

3. Risk of Impact: Check how likely it is for the gripper or the thing it’s holding to bump into a person or another object.

4. Risk of Entanglement: Think about the chance of hair, clothes, or other stuff getting stuck in the gripper.

5. Risk of Dropping Objects: Consider the risk of the gripper accidentally dropping what it’s holding, which could cause harm or damage.

6. Risk of Electrocution: Check if there’s a chance of getting an electric shock if the gripper isn’t insulated properly or touches electrical things.

7. Risk of Fire: Look for the risk of fire, especially if the gripper isn’t insulated well or touches things that can catch fire. Also, consider where the gripper will be working. If it’s in a dangerous place, think about those risks too.

It’s smart to get help from a professional risk assessor. They can find all the possible risks and suggest the right safety steps.

Conclusion:

In a nutshell, cobot grippers come in different types, each with its strengths and weaknesses. When choosing one, consider size, movement, safety, weight capacity, reach, speed, ease of use, and extra features.

Safety is vital with cobot grippers. Get professional help to spot risks and make things safer.