- 3D Vision Systems

- fruitcore robotics

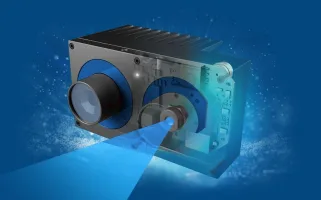

- horstVISION 3D

- Specifications

fruitcore robotics horstVISION 3D Specifications

Ranked Nr. 36 of 97 3D Vision Systems

fruitcore robotics’ horstVISION 3D interface enhances HORST robots by integrating 3D camera systems for advanced automation. This system enables robots to detect, identify, and process components adaptively, eliminating the need for predefined paths. It supports various 2D and 3D cameras, making the HORST robots more intelligent and versatile.

A key capability of horstVISION 3D is its position detection for disordered or irregularly shaped parts. The system creates a 3D image of the work environment, allowing HORST robots to reliably handle components from containers like wire mesh boxes or small load carriers. It manages to pick and place parts with precision, even from chaotic environments, ensuring correct orientation for further processing.

Additionally, horstVISION 3D facilitates intelligent parts handling and automatic depalletizing. Using CAD data, the system determines optimal gripping positions and calculates collision-free robot paths. It allows for precise detection and handling of components, even from inaccurately positioned pallets or stacks, improving efficiency and flexibility in manufacturing processes.

horstVISION 3D Alternatives

See all 174 3D Vision Systems

iRAYPLE 3D Cameras

Color | Monochrome

Basler blaze Time-of-Flight 3D Camera

Near-infrared | Working distance 940mm4.6/5 (1)

Basler RGB-D Solution

Color | Monochrome

COGNEX 3D-A1000 Dimensioning System

Monochrome | Near-infrared

COGNEX In-Sight 3D-L4000

Monochrome | Multispectral | Near-infrared | SWIR | Working distance 92-180 mm

COGNEX 3D-L4000 with VisionPro

Monochrome | Multispectral | Near-infrared | SWIR | Working distance 92-180 mm