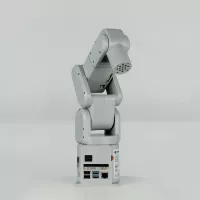

HITBOT Z-Arm 1832 Specifications

Ranked Nr. 272 of 207 Cobots

HITBOT Z-Arm 1832, is a cutting-edge robotic arm designed for precision, flexibility, and collaboration. This robotic arm has a compact design, measuring only 500mm in height and weighing 11KG, making it easy to deploy in various application scenarios.

The HITBOT Z-Arm 1832 is a 4-axis collaborative robotic arm with a maximum payload of 1KG and a rated payload of 0.5KG. It has a linear velocity of 1017mm/s and a repeatability of ±0.02mm. The J1 and J2 axes have an arm reach of 160mm and a rotation range of ±90° and ±143°, respectively. The Z-axis has a reach of 180mm, while the R-axis has a reach of ±1080°. This range of motion enables the robotic arm to perform various tasks with great precision.

One of the standout features of the HITBOT Z-Arm 1832 is its ease of use. It is designed to be simple but versatile, with a handheld teaching programming system that makes it easy to program and use. Additionally, it supports SDK secondary development, allowing users to customize its functionality according to their needs.

Another essential feature of the HITBOT Z-Arm 1832 is its collaborative and safe design. It supports collision detection, which ensures smart human-machine collaboration and prevents accidental collisions. This makes it safe to use in various settings, including those where humans are present.

The HITBOT Z-Arm 1832 is compatible with a range of HITBOT grippers, including the Z-EFG-8S, Z-EFG-12, Z-EFG-20, and Z-EFG-20S. It also has I/O ports for digital input and output (isolated) and customizable Z-axis height, with drag-to-teach capabilities.

In conclusion, the Hatbox's 832 Collaborative Robotic Arm, the HITBOT Z-Arm 1832, is a top-of-the-line robotic arm that is both compact and precise. Its flexibility, simplicity, and versatility make it an ideal choice for various applications, while its collaborative and safe design ensures that it can be used safely in various settings.

| Robot mass | 11 kg |

| Number of Axes | 4 |

| Repeatability | 0.02 mm |

| Payload | 1 kg |

| Extra info | J1 Axis: Arm Reach: 160mm / Rotatoin Range: ±90° J2 Axis: Arm Reach: 160mm / Rotation Range ±143° Z Axis: Reach: 180mm R Axis: Reach: ±1080° Linear Velocity: 1017mm/s Voltage: 20V/110V 50-60Hz DC24V/Power 320W Communication: Ethernet Customizable Z-axis height: 0.1-0.5 meter Z axis drag to teach: Yes Supportable HITBOT Grippers: Z-EFG-8S / Z-EFG-12 / Z-EFG-20 / Z-EFG-20S Working Environment: Temperature: 0-45℃, Humidity: RH20-80 (No Frost) I/O Ports: Digital Input (Isolated): 9+3 I/O Ports: Digital Output (Isolated): 9+3 Height: 500mm Machine Base Size: Footprint: 200*200*10mm Machine base size: Machine fixing holes spacing: 160*160 (with 4 M5*12 screws) Collision Detection: Support Hand-held drag to teach: Support |