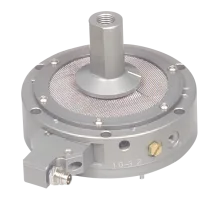

RAD Pneumatic High-Angle Specifications

Ranked Nr. 142 of 116 End of Arm Tools

The Pneumatic High-Angle Ultimatic™ Collision Sensor is RAD’s patented mechanical collision sensor that:

- Stops the robot* within 2 to 6ms of a collision to minimize costly damage to the robot and/or tooling. RAD’s collision sensor provides protection even if the robot itself is not moving.

- Offers a full 13° of angular compliance – 63% more than the original Ultimatic™ Pneumatic Collision Sensor model

- Absorbs the crash energy without releasing the air pressure in the unit thus preventing tooling ‘sag’ and eliminating the effects of compressed air being released into the environment.

- Automatically resets to within ± 0.0005″ (0.013mm) in x, y, and z dimensions and to within ± 0.017º rotationally to maximize uptime and eliminate the need for human intervention.

- Allows pneumatic adjustment so the user can easily change the amount of resistance the unit must encounter before signaling a collision.

- Has a compliance adjustment feature that lets the user determine the amount of deflection allowed before a signal is sent to your robot’s E-stop or controller.

Operating Principle

RAD’s Pneumatic High-Angle Ultimatic™ Collision Sensor works by establishing the minimal points of contact required to restrain all degrees of freedom (movement) in normal operation. When a collision occurs, external forces upset this balance thereby allowing angular, rotational, or compressive compliance. This motion opens a normally closed switch and sends a signal to your robot’s E-stop or controller.

Note: The Pneumatic High-Angle Ultimatic™ Collision Sensor can be used as a compliance (alignment) device by installing the unit without connecting the sensor switch. Please see the Compliance Devices section for more end-effector compliance options.

| Type |

|